Can't get PLA to stick well enough

Hi, I've had some warping in the past, but it really bothers me with the current PLA-filament I'm using: Orange PLA filament 1kg

I don't know if its because of the ambient temperature, which is getting colder due to the winter-season (The 3D-printer is in the garage) where its about 5 °C. However the the printer is inside my IKEA Lack Enclosure that I've isolated a little with some plastic bags. The ambient temperature inside the enclosure is around 18 °C. I have also used a 10mm brim and cleaned the plate with ISO-propyl alcohol before each run.

At first I had a decent print (object 1) with the filament -a little warped, but acceptable.

Then I had two failed prints (object 2) where I found the printer printing in mid air the next morning, because the scraping had made the filament stuck inside the extruder.

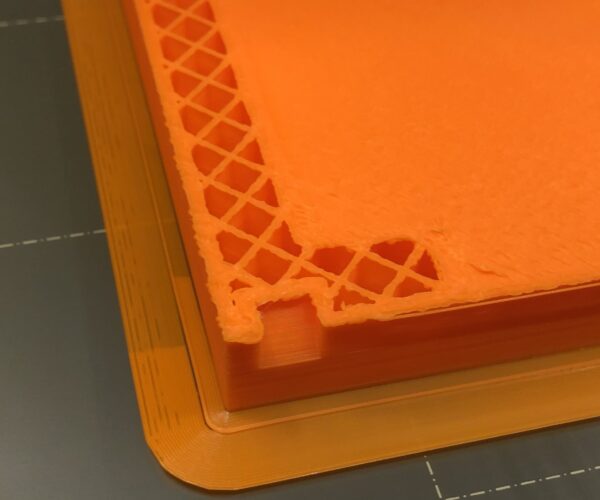

- By "scraping" I mean the corner of the print warped/snapped, so the nozzle was touching the previous layers, kind of dragging nozzle through the current layer. (Se Scraping-video) This makes the rest of the print, that was actually printed in the warped area very flattened and ugly:

Then I modified some stuff:

- I Isolated the Enclosure to get the ambient temperature inside to be around 18°C instead 12 °C.

- I set the elefantfoot-compensation to 0 (since I found that the brim was barely touching the object).

- I deleted the skirt, since it was messing a little with the brim.

- I read somewhere that users had more success with window cleaners, than Iso-propyl alchohol - so I tried that.

- I tried honeycomb-infill instead of the speed-mode's grid-infill (since I saw somewhere, that a guy got least warping with this).

- I reduced the vertical shells back to 2 (though I would prefer 3 -for a stronger part), for less plastic to shrink and pull the corner inwards)

- I also lowered the first layer z-axis a little since the brim lines wasn't connected everywhere (see left side on the image above).

Now the first layer seems better, though a little better adhesion would be nice. The print looks fine the first cm or so, then one of the corners warps a little and minor scraping happens above:

Also this little line (where the surface-layer is) appears and I don't know why.

I have ordered a little separate heater for the enclosure, so I can raise the ambient temperature even higher. It will be regulated so I can set it to 23 °C or something like that.

But is there other things I can do, in order to prevent warping?

- Does some of the modifications I did even matter in terms of warping?

- Can I somehow make the adhesion better (cheap and without making a mess each time I have to print).

- What's the ideal ambient temperature?

- Does infill/vertical layers matter that much?

- Is my brim big enough & should I make small pads in the corners too/instead?

- What causes the weird lines on the side?

- Also, my experience with warping before I used this filament, was that warping wouldn't block the nozzle the way it does now and the printer would simply just print "on top" of the warp and rest of the print would be fine/accurate. I haven't really experienced the scraping and rough surfaces before now.

Sorry for all the questions, I hope someone might be able to answer at least some of them 😀 Here's some specs:

Hardware and surroundings

Printer: Original Prusa i3 MK3s

Filament: Orange PLA filament 1kg

Ambient temperature outside enclosure: ~ 3-8 °C

Ambient temperature inside enclosure: ~ 16-19 °C

Software and print-settings

Printer Firmware: 3.9.1

Slicer: PrusaSlicer-2.2.0

Print settings: 0.15mm SPEED (modified)

- Elephant foot compensation: 0.2mm -> 0mm

- Brim width: 0mm -> 10mm

- Fill pattern: Grid -> Honeycomb

- Skirt Loops: 1 -> 0

Filament settings: Prusa PLA

Printer settings: Original Prusa i3 MRK3S & MK3S+

Best Answer by Neophyl:

Windex is an adhesion BARRIER, its used to reduce adhesion on the smooth sheet for materials that stick too well (like petg).

For cleaning the smooth sheet many of us use unscented/basic dish soap (like dawn/fairy) and LOTS of HOT water to rinse. Basically take your smooth sheet to the sink and using a clean paper towel and a few drops of dish soap detergent scrub the plate clean. Then rinse with lots of hot water. Dry with more clean paper towels and then avid touching the print surface, handle only by the edges. This will remove all trace of oils and grease from the plate. It works better than using IPA. This will give you the best bet of adhesion with PLA.

I've had similar large prints warp before but with a proper clean I found that the bed had bent up with the part and away from the magnets (which takes some doing). So on a reprint I added a couple of small binder clips on the edge placed to not get in the way.

Id say you need to adjust your live z slightly too as the picture of the brim is showing gaps between them but as you mention you already did that I'd assume you have already sorted that problem. Also if you haven't already make sure you have selected 7x7 mesh levelling from the printers LCD menu instead of 3x3. It gives a much better bed compensation as it probes 49 points instead of 9.

With that large a flat area in contact with the bed a brim is superfluous in my opinion. If its not sticking with that much surface area its not going to help.

Might also want to try cubic infill but more perimeters gives more strength than any corresponding infill.

The temp you have in your enclosure is fine for PLA, I regularly have around 20 degrees in winter (although my external isnt anywhere near as cold lol).

As well as the ambient temp you could also consider reducing your cooling % on the filament. That will reduce the chance of warping too. Something like 70% should still give enough cooling (except on bridges which has its own setting anyway).

The line around where interior flat areas are has been discussed lots on the forum. Its a combination of many things it seems, some of which is the slicer. Cant remember the threads title but a search for 'buldge' or 'bulge' should find it.

RE: Can't get PLA to stick well enough

Windex is an adhesion BARRIER, its used to reduce adhesion on the smooth sheet for materials that stick too well (like petg).

For cleaning the smooth sheet many of us use unscented/basic dish soap (like dawn/fairy) and LOTS of HOT water to rinse. Basically take your smooth sheet to the sink and using a clean paper towel and a few drops of dish soap detergent scrub the plate clean. Then rinse with lots of hot water. Dry with more clean paper towels and then avid touching the print surface, handle only by the edges. This will remove all trace of oils and grease from the plate. It works better than using IPA. This will give you the best bet of adhesion with PLA.

I've had similar large prints warp before but with a proper clean I found that the bed had bent up with the part and away from the magnets (which takes some doing). So on a reprint I added a couple of small binder clips on the edge placed to not get in the way.

Id say you need to adjust your live z slightly too as the picture of the brim is showing gaps between them but as you mention you already did that I'd assume you have already sorted that problem. Also if you haven't already make sure you have selected 7x7 mesh levelling from the printers LCD menu instead of 3x3. It gives a much better bed compensation as it probes 49 points instead of 9.

With that large a flat area in contact with the bed a brim is superfluous in my opinion. If its not sticking with that much surface area its not going to help.

Might also want to try cubic infill but more perimeters gives more strength than any corresponding infill.

The temp you have in your enclosure is fine for PLA, I regularly have around 20 degrees in winter (although my external isnt anywhere near as cold lol).

As well as the ambient temp you could also consider reducing your cooling % on the filament. That will reduce the chance of warping too. Something like 70% should still give enough cooling (except on bridges which has its own setting anyway).

The line around where interior flat areas are has been discussed lots on the forum. Its a combination of many things it seems, some of which is the slicer. Cant remember the threads title but a search for 'buldge' or 'bulge' should find it.

RE: Can't get PLA to stick well enough

@neophyl

Thank you very much for your answer! You pretty much answered all of them.

Windex is an adhesion BARRIER, its used to reduce adhesion on the smooth sheet for materials that stick too well (like petg).

Now it isn't the Windex brand, but I guess any window cleaner create a barrier then? I don't see a layer after the use of my window cleaner, but I stop using this and try the dish soap instead - Thanks!

Also if you haven't already make sure you have selected 7x7 mesh levelling from the printers LCD menu instead of 3x3. It gives a much better bed compensation as it probes 49 points instead of 9.

I haven't! Thankyou so much for telling me this, I haven't heard about this anywhere. I've read a lot of stuff in the manuals and other places by now. I had the feeling at one point that maybe 9 mesh-points wasn't enough, so I'm glad to hear this info.

The temp you have in your enclosure is fine for PLA, I regularly have around 20 degrees in winter (although my external isnt anywhere near as cold lol).

Glad to hear the temperature seems fine, I probably will increase the ambient temperature inside the enclosure by a few degrees to at least 20 °C

As well as the ambient temp you could also consider reducing your cooling % on the filament.

I haven't thought of the fan really, but I will try to set it a little down and see if it helps! I see the "Fan Speed -setting" has a Min & Max value, should I just turn both of those down to 70%? They are both currently 100%.

With that large a flat area in contact with the bed a brim is superfluous in my opinion. If its not sticking with that much surface area its not going to help.

I see what you mean, but if there's space for it I don't mind placing a brim around the object. Right now the middle of the object is what sticks to the surface, whereas the edges, well mostly the corners, are what lifts from the smooth sheet due to the warping. I fell that a brim can push that "edge" out a little and its also one of the first thing that pops up when searching about warping issues. So I think I'll keep using brims for now.

The line around where interior flat areas are has been discussed lots on the forum. Its a combination of many things it seems, some of which is the slicer. Cant remember the threads title but a search for 'buldge' or 'bulge' should find it.

Good thing to hear that the "line", "buldge" or "bulge" a common thing, I'll look a little into it, but its not my biggest concern atm. since I can just sand it of anyway.

- I'll try some of the things out and report back. I'll mark this topic "solved" when my prints has stropped warping. Thanks again, It's awesome to know there's small and easy fixes I can do now! 😉

RE: Can't get PLA to stick well enough

I know that some regularly poo-poo my suggestions of this, but I've found that it absolutely helps quite a bit when PLA does not stick as well as it should. I've found it's most helpful on small support footings (those small 'square waves') and on larger flat prints. For the latter, I'll dab a bit where the corners and/or edges will hit and it works quite well.

It's the Layerneer Bed Weld. It's not an alternative to a clean sheet, but it really helps on some of the tricky prints.

RE: Can't get PLA to stick well enough

@jsw

Alright -Thanks for the suggestion!

RE: Can't get PLA to stick well enough

I been struggeling with warping on large prints and the solution i found was clening the bed with acetone and a room temperature of 26C.

RE: Can't get PLA to stick well enough

The thing that works consistently well for adhesion for me on PLA, PETG and TPU is Blue painter's tape and glue stick.

With the painter's tape and glue I use the following zOffsets:

-0.023 for PLA

-0.043 for PETG and TPU

and for .2mm layer height I use a .3mm first layer. sticks every time. Just replace the tape every few prints.

RE: Can't get PLA to stick well enough

Consider Hair Spray! Cough, nudge.

--------------------

Chuck H

3D Printer Review Blog

RE: Can't get PLA to stick well enough

@cwbullet

I've not tried this yet. I probably should. I've done:

simply glue,

magigoo

the painters tape

and painter's tape + glue

The latter has produced best adhesion for me. I might have to break down and try the hair spray. I like that I don't have to worry about taking the plate somewhere I can spray it. I'm down in the basement so it means extra trips upstairs. Though admittedly I could use the exercise. I figure with the tape though, I never have to worry about pieces of the PEI sheet coming off with the model!

RE: Can't get PLA to stick well enough

I have found great adhesion and it is easy to apply.

If it does not work, you have either bad filament or your Z is not low enough.

--------------------

Chuck H

3D Printer Review Blog