Cannot solve my printing issue

Hi,

This this my first post on this forum so I would like to say hello to everyone.

I own a MK2S since 2 years and a MK3 since 6 months.

I usually manage to solve my printing issues by myself but I'm facing a problem I can't explain :

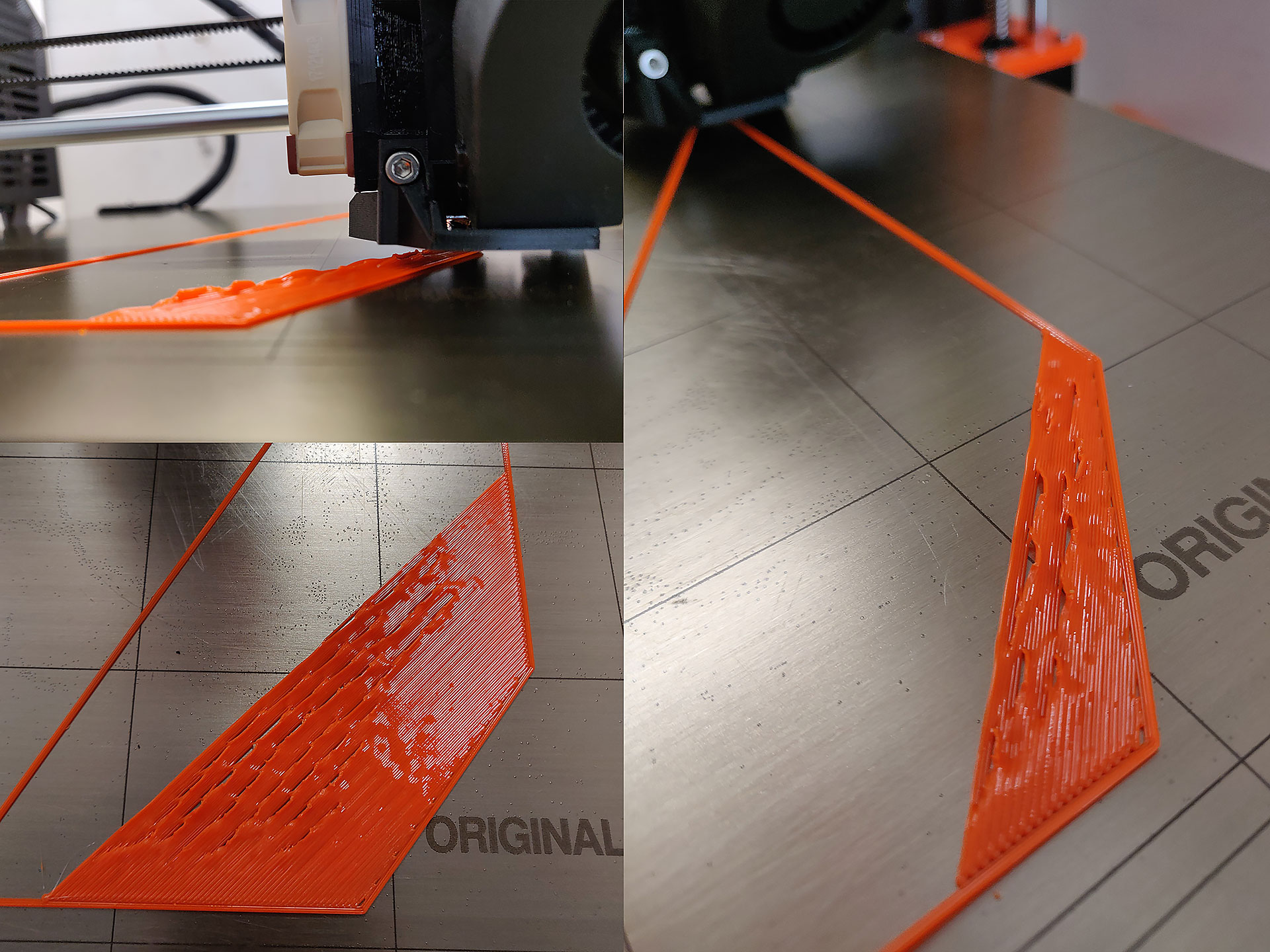

Here is a picture of the problem :

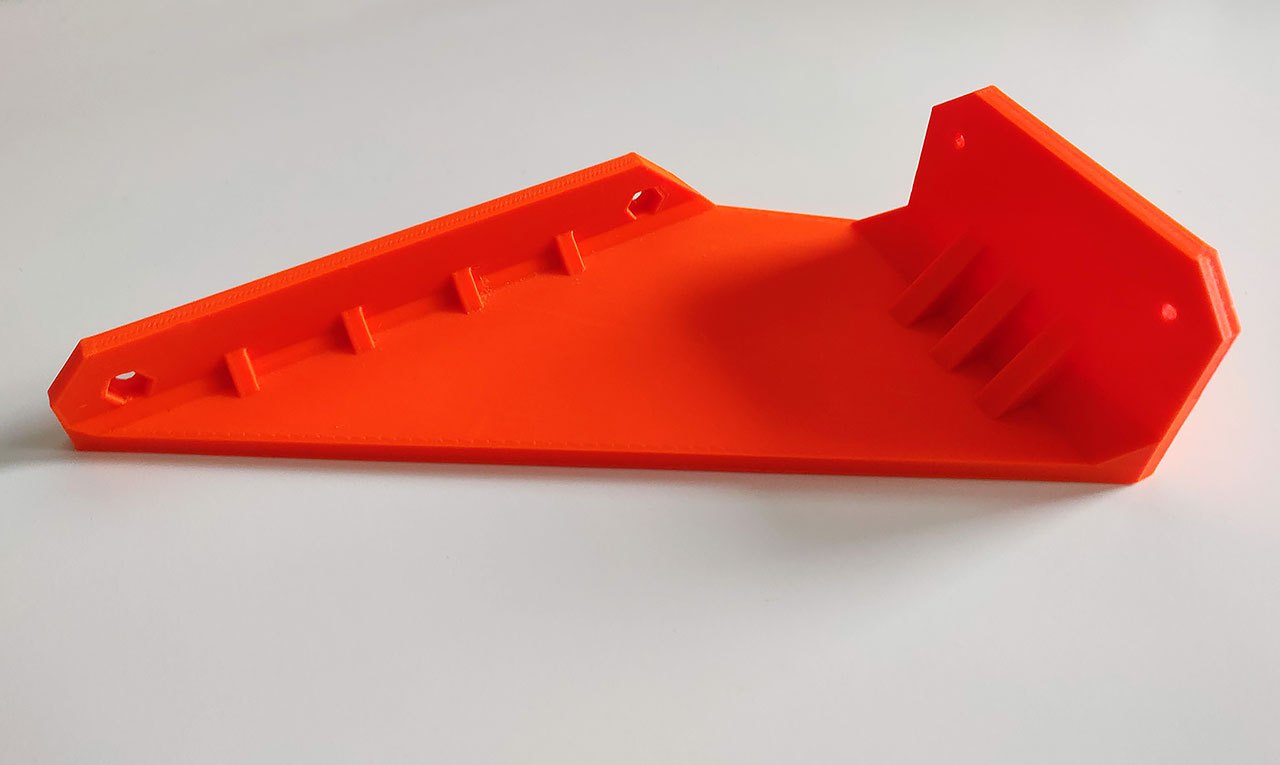

The printed part is the PSU_BRACE used for the official Prusa enclosure.

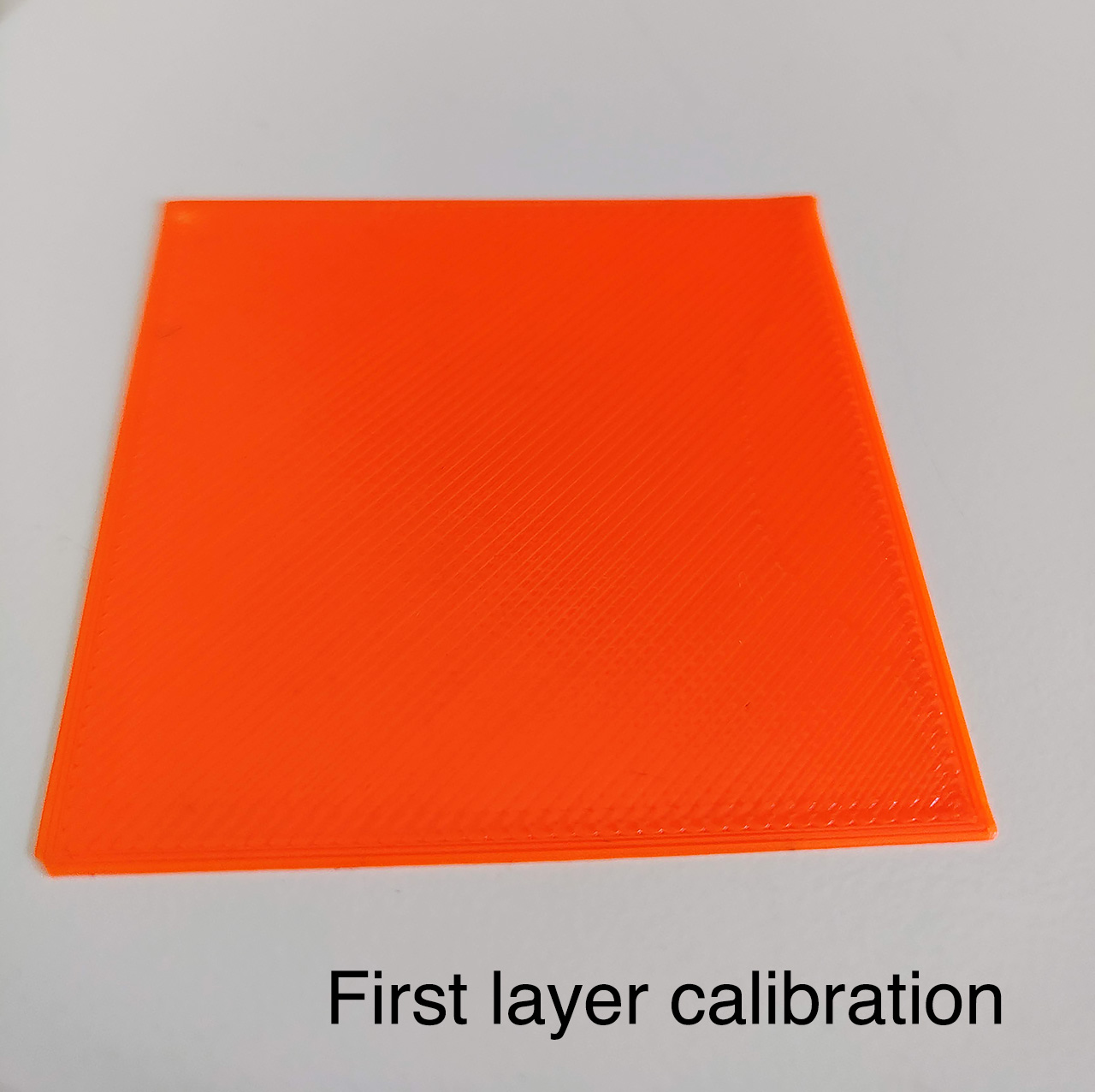

So I performed the XYZ calibration process again , recalibrate the extruder and set the first layer height. Everything seems to be ok

But I get the same problems when I try to print the PSU brace.

Filament used is Prusament orange PETG.

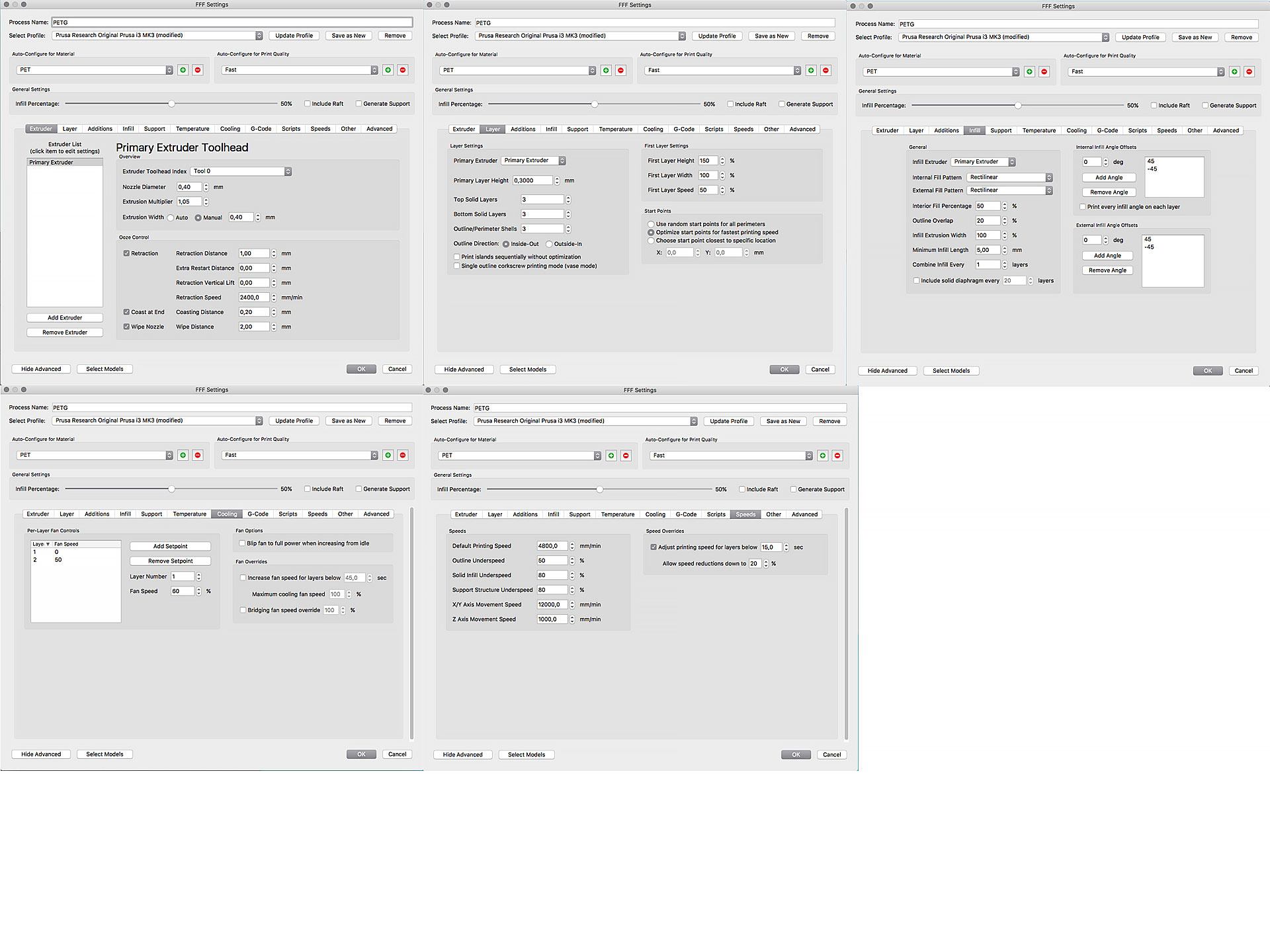

Slicer is simplify 3D with the following settings :

Does anyone have an idea of the problem ?

Thank you in advance.

Vincent.

Re: Cannot solve my printing issue

Looks to me like you have adhesion issues in this area of the plate. Try to roughen the surface/clean the bed/wash the bed/use glue stick.

You're printing with 0.4 nozzle and 0.3 layer height which is not recommended and might lead to this kind of issues. Try with 0.2 instead.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Cannot solve my printing issue

Hi Nikolaï,

You are right, i was an adhesion issue.

Following your advise I reduced the layer height to 0.2 mm and lower a bit more the distance between the nozzle and the bed via the live adjust Z.

This time the the print came out pretty well.

I'm suprised because I usualy print PETG with a 0.3 mm layer height without any problem. I assume that the difference here is the greater contact surface between the bed and the printed part ?

Thank you very much for your answer.

Regards.

Vincent.

Re: Cannot solve my printing issue

I'm glad it was helpful.

Correct. If you still want to print with 0.3, you need to make sure you have the best possible contact to the bed. You also need to pay attention to the speed as you're on the edge with 0.3 layer height for the 0.4 nozzle.

I would recommend to use 0.6 nozzle for this purpose, you would get much better layer bonding.

BTW: This part doesn't work well if printed in PETG. I did the same mistake. It's to flexible for this purpose (check the bending once installed). It's better to print it in PLA.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Cannot solve my printing issue

Hi Nikolaï,

I will consider switching to a 0.6 mm nozzle, thank you for the tip.

Considering the PSU brace, you are right, it is too flexible. I wanted to avoid PLA because temperature can get high in the enclosure when the printing bed is set to 110°C. I will print this part again 🙂

Thank you again.

Vincent.