RE: Buldge when print reaches "solid" layers

Just printing another test.

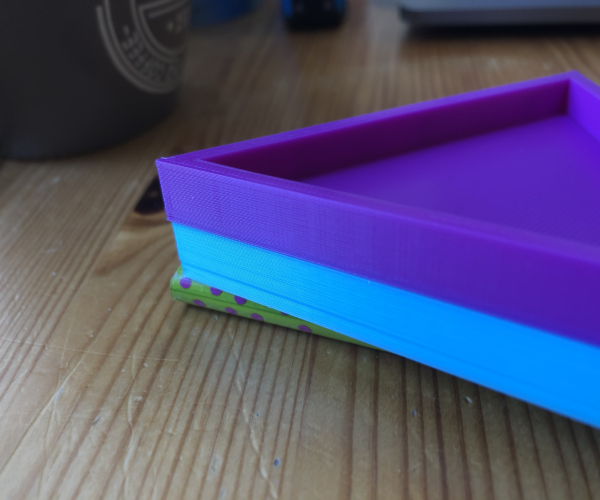

But the first two are done.

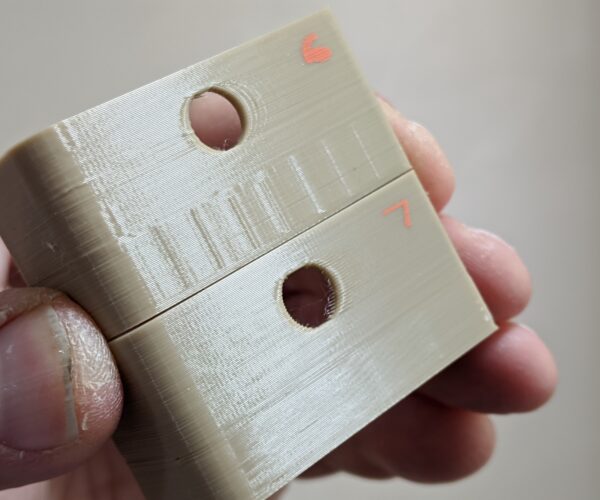

Light Blue = Prusa (Default Quality 0.2 Temp Bed 60 Filament 200) - Times 1h 3m

Purple = Qidi (Default Fine 0.2 Temp Bed 60 Filament 200) - Times 57m

Interestingly Prusa support has sent me an email acknowledging an issue with Prusa Slicer and the developers are working on this problem.

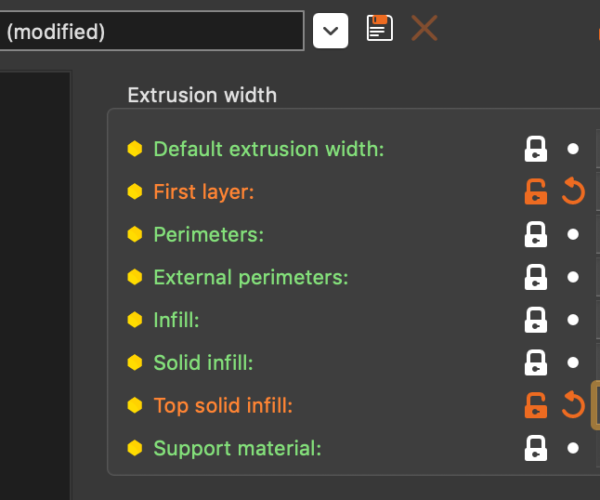

"What you can still try with the current version and works for my colleague is changing the extrusion width in PrusaSlicer for all options to the same value (for example 0.45), even for supports if needed. In some models where artefact like this happed, it might help resolving this issue. Thank you for giving it a shot, I really hope it helps to improve the quality of your prints."

So after my print has finished. I will do one with @lowfat's recommendations and with Prusa Supports.

If this little test comes out looking better I will do a full-size test that I used the photo of the two pots from above and report back. I dread to think how much filament I have gone through testing 🙂

RE: Buldge when print reaches "solid" layers

Just to be thorough: Put a brim (3mm or so) on the prints. In doing some of this testing, my print surface was slightly contaminated and in my rush to get results, I let up on the cleaning. The Prusa surface can be touchy in this regard. A bit of warping will definitely contribute to this issue.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

Interestingly Prusa support has sent me an email acknowledging an issue with Prusa Slicer and the developers are working on this problem.

"What you can still try with the current version and works for my colleague is changing the extrusion width in PrusaSlicer for all options to the same value (for example 0.45), even for supports if needed. In some models where artefact like this happed, it might help resolving this issue. Thank you for giving it a shot, I really hope it helps to improve the quality of your prints."

That is all of the information anyone here needs. Prusa has acknowledged the issue with PrusaSlicer. Any other tweaks and attempts to resolve the issue won't fix the root cause of the issue.

That is good news, and I expect it will be solved properly now.

Drew Read

RE: Buldge when print reaches "solid" layers

@drewread

“But I have consulted your issue with my colleagues and it seems to be related to PrusaSlicer not the printer itself. Our developers are working on this and I really hope they improve the behavior in the future releases”

RE: Buldge when print reaches "solid" layers

I really don't understand the motivations of people who hijack these threads and turn them into finger pointing and blamestorming. The reality is that, whatever the causes, there are (unsurprisingly) people on these forums who are using Prusa printers with PrusaSlicer who wish to get the best results possible. We're trying to discuss how to improve results, and yet some feel compelled to jump in and derail the discussion with "AHA! I KNEW it was Prusa!" posts that are unhelpful at best.

So far this week, we've seen assertions made that...

- The problem is clearly exclusively the fault of the Prusa i3 Mk3.

- The problem is exclusively the fault of PrusaSlicer.

If making one of those points is your only reason for being here, message received. Feel free to move on to more important things.

So far as the "admission" by Prusa, Team Prusa has indicated they are aware of a common FFF printing artifact and are working on improving the slicer. Peri0d. I see nearly identical discussions in the Cura and ideaMaker forums. FFF printing does not produce perfect parts, and slicer developers are constantly trying to improve results. That doesn't meant that ONLY their slicer has this or myriad other limitations. The entire issue of varying perimeter extrusion width was covered early on in this discussion, and (not surprisingly) impacts vertical wall finish. Stop putting words in peoples' mouths.

Working on an issue is not an admission that they are solely responsible for the problem. What is artfully being left out of the discussion is that Prusa is one of a handful of companies actually developing slicers that are used by people purchasing inexpensive clone printers from companies that provide almost no support. It takes very twisted logic to suggest that one of the few companies working on a slicer issue is responsible for a common problem shared by all printers of this type, even those produced by companies that are notoriously poor at support.

In the hope that there are some folks still trying to read this who are using a Prusa printer with PrusaSlicer and want to improve their results, I'm going to press on with actual suggestions for slicer and printer settings. Just so I don't get more words put in my mouth again, here's my take on the entire situation:

- Variations in vertical wall surfaces are a common artifact of FFF printing.

- Different technologies used in FFF printers often trade one issue off for another. Anybody using a 3D printer as the basis for a business or requiring a high degree of precision should investigate cartesian, corexy, delta and a host of other printer designs to identify what best meets their needs. For smoothest surfaces, FFF printing is not going to be an ideal technology and alternatives like resin should be considered.

- In any case, the Prusa Mk3 (and Artillery Sidewinder X1, Creality Ender 3) are bed slingers. If you bought one, you bought a bed slinger.

- Bed slinger designs such as Prusa and the majority of consumer-grade printers in the price range are moving a much larger mass around in the Y axis than other designs, so inconsistencies in walls are a concern, regardless of the slicer. Hotend weight can contribute to X axis defects, and extruder weight adds to this in direct drive designs. This is a physics challenge and not exclusive to Prusa printers.

- Those of us on this thread are presumably adults who made the conscious decision -- with or without research -- to purchase an i3-style bed slinger and want to use it to its maximum potential and have come here for assistance and discussion.

- Those of us on this thread are presumably adults who made the conscious decision -- with or without research -- to use PrusaSlicer (a decision I have absolutely no problem debating on a point-by-point basis) and want to use it to its maximum potential and have come here for assistance and discussion.

- Results will vary with printer, print and filament settings. Whether the results are "good enough" is ultimately up to the user, but anybody using the printer and slicer regularly is well served by understanding the impact of settings for their chosen printer and slicer.

- PrusaSlicer is under constant and frequent development, and has changed and can be expected to change rapidly.

With that, I'm going to continue on with suggestions for test prints and settings to pin point specific problems and identify possible solutions. With any luck, we may identify some issues that are useful for the Prusa development team as well as other slicer development teams, and ultimately benefit all users, regardless of chosen products.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

Just printing another test.

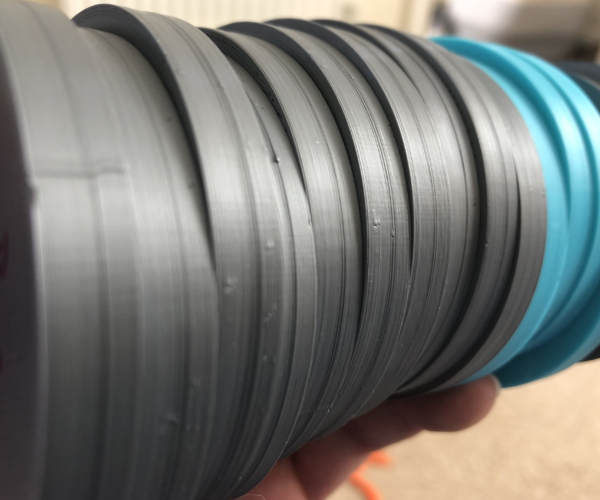

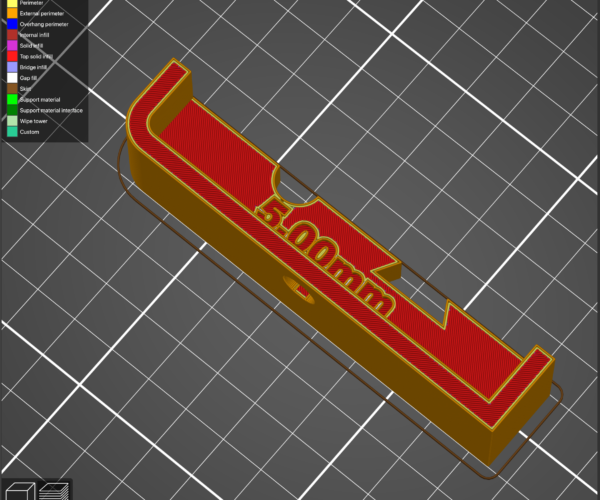

In the hopes that you're still interested in improving your prints and that we can move past the blamestorming, I'm working on some test pieces that we can all use as a baseline for identifying issues and improving results. I'm hoping to produce a 1 hour print that will trigger worst-case results. I've extended the length to 100mm to better show the effects of perimeter speed. The final will actually have 5mm thick walls to match your pot design... though I forgot to make them thicker than 3mm for this print (wups).

Again, for testing, I would add a brim to ensure warping is not part of the problem. That can really cause issues that can't be fixed in the slicer.

I'm also thinking about other physical factors. What size nozzle do you use on your Qidi? A larger nozzle will produce appreciably less back pressure, and back pressure might contribute to uneven filament flow. I'm going to mount a 0.4mm nozzle to reflect the Prusa default, try to develop a print that is consistently bad with the Prusa slicer defaults, then try a different nozzle and other settings.

I'll put up a full set of STLs once we get a good "worst case" result. I'm happy to share the Fusion 360 (amateurish) source files for anybody interested.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

Bob,

I was not blamestorming. I was adding the part from the email for clarification. Apologies if this is how it came across.

The photo - the part is not warped. bad photo maybe 🙂 but I was trying to get the light right so it showed the worse of both parts.

And yes I am still very interested in getting my Prusa to work the way I think it should. Since I want to print parts on it now not at some point in the future.

I have now printed test 6 parts off with various settings (not doing anything on Qidi as I think that point is now done).

I am trying to understand the Prusa Support message

"extrusion width in PrusaSlicer for all options to the same value (for example 0.45)"

So I see on your site you have some profiles which I grabbed and had a look at and you have your extrusion width to 0 which I understand to 0.4 (for my nozzle) does that mean the Quality Prusa profile is simply best guessing the over extrusion needed? and do I have to re-do filament calibration to change the extrusion width without over extrusion?

Why would Prusa over extrude when you know the width and calculate off that?

RE: Buldge when print reaches "solid" layers

I was not blamestorming. I was adding the part from the email for clarification. Apologies if this is how it came across.

Understood, and thanks for that clarification. For what it's worth, I don't think you're the individual trying to derail the conversation. I appreciate your insights into the Qidi as I came very close to ordering a Max myself.

The photo - the part is not warped. bad photo maybe 🙂 but I was trying to get the light right so it showed the worse of both parts.

I have had warping throw off my results and waste a LOT of time, so I will likely include a 3mm brim as the basic test. "Success" will be printing a part with good vertical finish without a brim.

And yes I am still very interested in getting my Prusa to work the way I think it should. Since I want to print parts on it now not at some point in the future.

I think (and hope) most of us in this thread are after the same. I appreciate your feedback and the discussion. I find different techniques work for different specific challenges and it's always interesting seeing what others are encountering. Yours is interesting because it's a "thick wall" issue, not just the "thin wall" problem, so things like gap fill are less of an issue than infill. I'm more than happy to concede that some things are simply limitations, but I do want to understand why.

I have now printed test 6 parts off with various settings (not doing anything on Qidi as I think that point is now done).

I am trying to understand the Prusa Support message

"extrusion width in PrusaSlicer for all options to the same value (for example 0.45)"

I believe what they are suggesting is using a consistent widty (e.g. 0.45mm for ALL feature types). Settings like this:

It's interesting to note that Prusa's profiles have changed over the years. When someone says "PrusaSlicer/Slic3rPE does this", you want to get the specific settings as the profiles do change over time. Unlike some of the other often-touted low-cost manufacturers, Prusa actually provides the slicer, functional profiles and updates at no additional charge. This is a strength, but can also add surprises. That's why I developed my profiles. I update them, but I know when they've changed, what's changed and why. I do peek at Prusa's changes now and then, and it's interesting watching them evolve.

So I see on your site you have some profiles which I grabbed and had a look at and you have your extrusion width to 0 which I understand to 0.4 (for my nozzle) does that mean the Quality Prusa profile is simply best guessing the over extrusion needed? and do I have to re-do filament calibration to change the extrusion width without over extrusion?

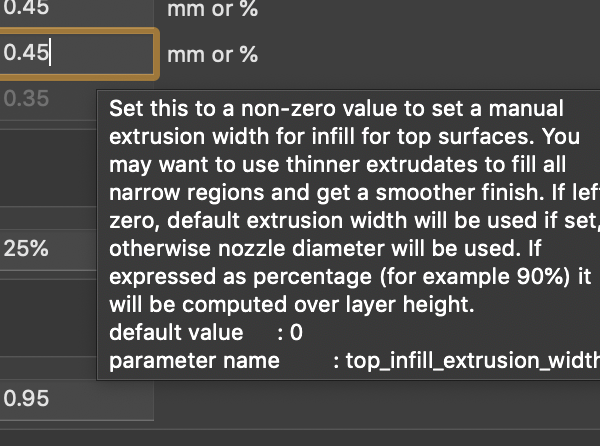

PrusaSlicer was originally based on Slic3r, and a lot of the underlying approach has not changed. By selecting 0, you are letting the slicer make a slice-time calculation based on your specified nozzle size. If you hover over those boxes, a small (and annoyingly fleeting) popup will explain.

The exact value will vary depending on the feature type being printed, but will range from the default extrusion width to something like 1.125% of the default. By setting 0 in my Print Settings profiles, I can use one profile with any nozzle size and save a lot of duplication when maintaining profiles. The results have been working very well for me, but Prusa's suggestion of using a fixed size (0.45mm) is definitely worth a shot.

Why would Prusa over extrude when you know the width and calculate off that?

IME, you run into finish quality issues with the slightest bit of over extrusion. On vertical walls, the inner perimeters are printed 1st, so if they over-extrude, that filament has to go somewhere. It can't go down. Any that goes up will get squished on the next pass of the nozzle. Some will go out the sides, impacting adjacent extrusions. As to the cause, again my experience, having slicer settings that don't accurately reflect your actual printer or filament settings can cause a mis-match between the slicer's understanding and the real world. Small over-extrusion is a common result, and this will contribute to vertical surface finish and stringing issues. I've put more of my notes on the topic here if you're interested. So while PrusaSlicer can produce very good results if the filament and printer mechanics are closely tuned -- a big part of the reason Prusa released Prusament is to control the filament part of the equation since they already control the printer mechanics -- it can't tell how closely any other filament matches your settings. I always recommend measuring and averaging the filament diameter and doing an extrusion multiplier calibration with a new brand and type of filament for this reason. The more closely your settings match the real world, the better the print will be and the less compensation (or "masking") will be required to work around issues.

We will never achieve perfection, but we can work on understanding our tools and getting the best results possible!

Thanks for sharing your issues and insights.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

@bobstro

Let me know when you have an STL happy to standardize on a test part.

Just wondering about a photo with settings as this would help everyone from repeating the testing.

RE: Buldge when print reaches "solid" layers

@bobstro

Let me know when you have an STL happy to standardize on a test part.

Just wondering about a photo with settings as this would help everyone from repeating the testing.

Good idea. I'm still adjusting for the "thick wall" challenge -- it's always hard to get something to break when you want it to -- but I'll upload a config file or bundle. I would be curious to see what results you get with either my SPEED (2 perimeter, faster speeds) or QUALITY (3 perimeter, slower speed) profiles.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

@bobstro

I have been using a 70mm x 10mm shelled to 5mm as a test (1-hour print) which gives me a good indication of a full-size print (pot). But I suspect the test is quite limited as its only testing for this issue I see. I am quite happy to go back to basics and have a more in-depth model

I then increase to 100 and 150mm to see how the results scale up if they look promosing.

I did some more today inc your profile to add to my collection. I need to print more blue then I can have a very big connect 4 set 🙂

Feedback on test print?

At 100x20mm, this prints in ~1h20m. I added some irregularities to the rear surface to see if rounded or cornered features impact the print. I suppose I should isolate those to specific layers (angles on one layer range, circular on another) but this is hopefully large enough to highlight artifacts without taking forever to print ... or at least break forever down into manageable chunks. I'd appreciate any feedback. Tim, any thoughts on what might be worth adding?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

@bobstro

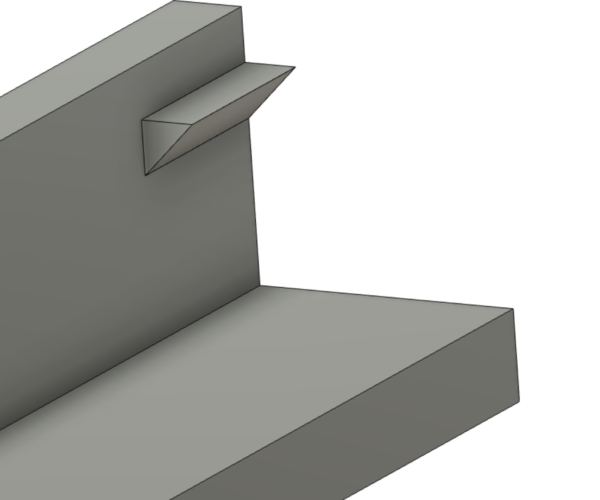

Can you add a lip section a few mm from the top like > but with a flat top. on a part of the model that sticks out by 3mm. Does not have to be long maybe 5mm?

RE: Buldge when print reaches "solid" layers

I have been using a 70mm x 10mm shelled to 5mm as a test (1-hour print) which gives me a good indication of a full-size print (pot). But I suspect the test is quite limited as its only testing for this issue I see. I am quite happy to go back to basics and have a more in-depth model

I then increase to 100 and 150mm to see how the results scale up if they look promosing.

Hmm. I may have to bite the bullet and go larger then. Was hoping to combine rounded and squared features into one fast test print, but that might not be effective. Let me plonk a big circular tower at the rounded end and see how that works.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

@bobstro

Can you add a lip section a few mm from the top like > but with a flat top. on a part of the model that sticks out by 3mm. Does not have to be long maybe 5mm?

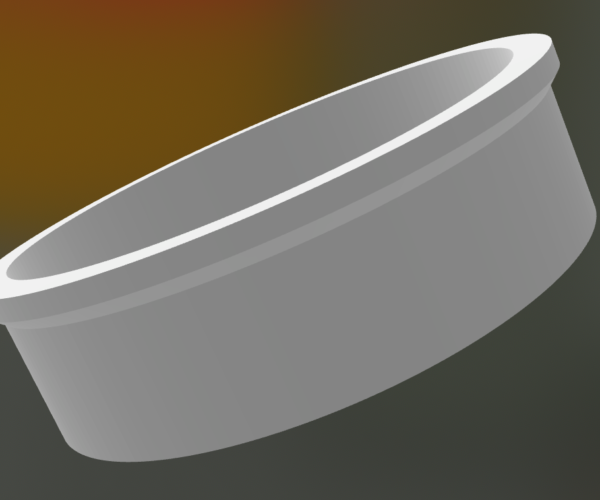

Like this? 75mm inner diameter, 5mm thick wall, 3mm overhang with chamfer at top.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

@bobstro

Kind of. Let me draw a picture

RE: Buldge when print reaches "solid" layers

I really don't understand the motivations of people who hijack these threads and turn them into finger pointing and blamestorming. The reality is that, whatever the causes, there are (unsurprisingly) people on these forums who are using Prusa printers with PrusaSlicer who wish to get the best results possible. We're trying to discuss how to improve results, and yet some feel compelled to jump in and derail the discussion with "AHA! I KNEW it was Prusa!" posts that are unhelpful at best.

So far this week, we've seen assertions made that...

- The problem is clearly exclusively the fault of the Prusa i3 Mk3.

- The problem is exclusively the fault of PrusaSlicer.

If making one of those points is your only reason for being here, message received. Feel free to move on to more important things.

So far as the "admission" by Prusa, Team Prusa has indicated they are aware of a common FFF printing artifact and are working on improving the slicer. Peri0d. I see nearly identical discussions in the Cura and ideaMaker forums. FFF printing does not produce perfect parts, and slicer developers are constantly trying to improve results. That doesn't meant that ONLY their slicer has this or myriad other limitations. The entire issue of varying perimeter extrusion width was covered early on in this discussion, and (not surprisingly) impacts vertical wall finish. Stop putting words in peoples' mouths.

Working on an issue is not an admission that they are solely responsible for the problem. What is artfully being left out of the discussion is that Prusa is one of a handful of companies actually developing slicers that are used by people purchasing inexpensive clone printers from companies that provide almost no support. It takes very twisted logic to suggest that one of the few companies working on a slicer issue is responsible for a common problem shared by all printers of this type, even those produced by companies that are notoriously poor at support.

In the hope that there are some folks still trying to read this who are using a Prusa printer with PrusaSlicer and want to improve their results, I'm going to press on with actual suggestions for slicer and printer settings. Just so I don't get more words put in my mouth again, here's my take on the entire situation:

- Variations in vertical wall surfaces are a common artifact of FFF printing.

- Different technologies used in FFF printers often trade one issue off for another. Anybody using a 3D printer as the basis for a business or requiring a high degree of precision should investigate cartesian, corexy, delta and a host of other printer designs to identify what best meets their needs. For smoothest surfaces, FFF printing is not going to be an ideal technology and alternatives like resin should be considered.

- In any case, the Prusa Mk3 (and Artillery Sidewinder X1, Creality Ender 3) are bed slingers. If you bought one, you bought a bed slinger.

- Bed slinger designs such as Prusa and the majority of consumer-grade printers in the price range are moving a much larger mass around in the Y axis than other designs, so inconsistencies in walls are a concern, regardless of the slicer. Hotend weight can contribute to X axis defects, and extruder weight adds to this in direct drive designs. This is a physics challenge and not exclusive to Prusa printers.

- Those of us on this thread are presumably adults who made the conscious decision -- with or without research -- to purchase an i3-style bed slinger and want to use it to its maximum potential and have come here for assistance and discussion.

- Those of us on this thread are presumably adults who made the conscious decision -- with or without research -- to use PrusaSlicer (a decision I have absolutely no problem debating on a point-by-point basis) and want to use it to its maximum potential and have come here for assistance and discussion.

- Results will vary with printer, print and filament settings. Whether the results are "good enough" is ultimately up to the user, but anybody using the printer and slicer regularly is well served by understanding the impact of settings for their chosen printer and slicer.

- PrusaSlicer is under constant and frequent development, and has changed and can be expected to change rapidly.

With that, I'm going to continue on with suggestions for test prints and settings to pin point specific problems and identify possible solutions. With any luck, we may identify some issues that are useful for the Prusa development team as well as other slicer development teams, and ultimately benefit all users, regardless of chosen products.

Bob, as this is pretty clearly directed at me I will gladly unsubscribe from this post so as to not bother your extremely sensitive nature. This will be resolved by Prusa when they fix the slicer anyway.

I have said from my first post that it was an issue with Slic3r and it's derivatives and I have not wavered from that fact, and now that Prusa has acknowledged that fact I'm confident they will resolve the issue.

For what it is worth: Nowhere did I ever say I expect a perfect print from my machines, nor that the issue was specifically with Prusa machines. So in regards to putting words in mouths, you should perhaps look in a mirror.

I wish you luck in your future endeavors.

Drew Read

RE: Buldge when print reaches "solid" layers

[...] I wish you luck in your future endeavors.

Thank you for your invaluable contributions in helping other identify and address these problems.

These were not sliced with PrusaSlicer/Slic3r:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

[...] I have some parts I printed on the same Railcore printer, printed in CF PETG it doesn't have the bulge but the part printed in pure PETG does have the bulge. I'm really stumped...

Sorry, didn't mean to ignore you in all the fun. Have you calibrated your slicer settings for the filament? I find averaging the filament diameter, determining a good extrusion multiplier for each filament type and entering those values in the slicer helps a lot. I'm assuming you're using PrusaSlicer. Is that correct?

CF PETG will certainly be more viscous than simple PETG. PETG is interesting in that it flows much more readily than PLA as optimal temps. Perhaps this is a hint? At some point, I'll switch over to PETG and try some of these prints. I happen to have Paramount PLA and PETG on hand.

Good data point on using another printer with similar results, thanks.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…