RE: Buldge when print reaches "solid" layers

@bobstro

I can't in all honesty say that I did, although I know I screwed with it at some point. I can run a test that just changes this and see what happens.

Did you have good luck with this?

RE: Buldge when print reaches "solid" layers

[...] Did you have good luck with this?

I can honestly say that the realization that the extrusion mutliplier is critical to quality prints has been the biggest epiphany of my (2 year) 3D printing experience. It impacts surface finish, stringing, filament snagging and likely other factors.

This of it this way: Your slicer produces gcode to move and extrude filament based on its understanding of your printer and filament. If your filament deviates from this "ideal" setting, your gcode doesn't match the real world. You likely get under- or over-extrusion, usually in small amounts. However, as a layer prints -- particularly solid layers -- any over-extrusion has to go somewhere. It can't go down. If it goes up, the next layer pushes it down. The path of least resistance is sideways. This means a solid layer may protrude slightly more than a hollow layer, possibly accounting for the lines and bumps we see on external walls.

I've realized that getting the filament diameter and extrusion multiplier right so the slicer settings most accurately models the real world makes a huge difference. The biggest improvment fror me has been reducing stringing. I can get by with 0.2-0.4mm retraction, 0.4mm z-lift and no wipe with minimal stringing once I calibrate for the filament. This has the added benefit of speeding up prints due to fewer retraction and wipe moves for each layer.

I also find that slowing down (for accuracy and reduction of ringing), and an additional perimeter (more wall thicknesses to isolate external surface from internal variations help.

I recently compiled my notes on filament calibration here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

Is there a github bug listed for this issue? It really seems like an issue with Slic3r - especially when switching to another slicer cures the problem with the same model.

Drew Read

RE: Buldge when print reaches "solid" layers

Apparently I cannot edit my post above, I found a myraid of Github posts, none of which actually acknowledge the problem or seem to be moving towards a resolution. This definitely seems like an issue with the Slic3r and its variants. A rather large issue (pardon the pun.) All of the tweaks listed above try to mitigate the problem, but it doesn't deal with the fact that this is a problem. If switching to another slicer (Cura) essentially eliminates the problem without all of the other tweaking (that may or may not cure the problem and may or may not cause other undesirable effects) then this is something that should be looked at pretty seriously by the developers.

I for one up-vote this a a relatively major issue that causes ugly flaws in prints, and it is most certainly not resolved.

Drew Read

RE: Buldge when print reaches "solid" layers

There a fine line between hacks, tweaks and calibration. My preference is for a slicer that is most accurate if I've used the correct settings for my printer and filament.

Unlessy you've spent time calibrating your printer and filament settings, I'm not going to consider PrusaSlicer broken unless you can demonstrate that the results you get with Cura are also more accurate. I've got PrusaSlicer producing good and accurate results. I can get 0.15mm tolerances to work, and dimensional accuracy is more than sufficient for my purposes. If implementing a "fix" to mask your issues causes problems for my prints, I'll be more upset! This isn't meant as a slight, but we see a lot of users suggesting that they have been granted the one true perspective and that other knowledge is false. Try slowing down and see if that fixes things, then go from there.

I started with Simplify 3D, tried and rejected early Slic3r, used Cura, wandered down the path of KISSlicer and ideaMaker, and finally have settled on PrusaSlicer for my purposes. There's nothing wrong with preferring Cura. Just be aware that unless you can explain why you're getting better results with Cura, you are just as likely to encounter problems if you move away from the defaults. Despite the claims of some YouTubers, there are no magic profiles that will work with any combination of layer heights and filaments. (Pet peeve, especially when said personality sells no-name generic filament with their label on it.) 3D printing is probably more like cooking than engineering.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

I have been fighting these issues and had no help from Prusa's support.

I have flipped over to Slicer++ which is giving me some very good results, but I have spent several hours tweaking to get it just right.

I have calibrated my printer to the best of my knowledge and understanding of the process and dimensionally all my prints are very good unless they need some internal floor (solid layer). Given the current issues with the printing, I don't think this is a printer I could recommend. I cannot reliably dimensional prototype anything with internal floors on the MK3s and tend to use my Chinese printer for those.

I can print the exact same object on my out the box Chinese printer and not have this issue at all - So I don't buy the "It physics" I have seen commented several times on several threads.

I even bought a copy of S3D to try and see if the issue would go away with another slicer other than Cura. It did not so I got a refund 🙂

I got very close with PS but I had to make some sacrifices to do so (As mentioned above "Hacked". So I keep coming back to this issue periodically.

I am very surprised that Prusa don't seem to be commenting more on this problem and annoyed that the support I thought I was buying into is simply not there.

I am very curious to see if this issue is present on the Mini.

I also think this is an issue at the firmware/hardware level and not at a slicer level. I see that you can minimize the issue to varying degrees but not eliminate it completely. I think I have it sussed and then a new dimensional object will then present the problem again.

RE: Buldge when print reaches "solid" layers

[...] I also think this is an issue at the firmware/hardware level and not at a slicer level. I see that you can minimize the issue to varying degrees but not eliminate it completely. I think I have it sussed and then a new dimensional object will then present the problem again.

Are you suggesting that the Mk3 is incapable of producing smooth surfaces on parts with internal surfaces? Is so, it should be impossible for anybody to print your part successfully. Can you zip and upload one of your parts so we can make this determination?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

@bobstro

Can you print them successfully without a step/line/bulge?

also I can only speak from the mk3s..

Seemed to me from Prusa support this was the normal.

But I would love it if it is a slicer setting issue or a tuning issue.

try making a cylinder 150mm by 20mm and shell to 5mm

Use 5 top layers 4 bottom and whatever perimeters and infill you usually use. Print at 0.2 with a 0.4 nozzle.

You can stop the print at 10mm as it’s usually quite obvious.

As I said before I thought I had this solved but then I made a triangle shelled to 5mm and the line appeared all the way through and onto a solid print on the plate at the height of the internal floor of the triangle. If I don’t print top layers then the issue never happens.

RE: Buldge when print reaches "solid" layers

Bob, everyone appreciates your scientific approach to this issue, and certainly tweaking all of those things you mention can help to make it less prevalent, but let's not ignore fact that the issue still manifests even after endless calibration and tweaking. Certainly there are many Prusa users that don't want to have to spend their days tweaking and calibrating until they turn blue in the face... they simply want to print with the best printer on the market and have good results.

I am telling you right now that I have calibrated my machines (I own 4 Prusa printers currently) and I have spent the time to get things as close to perfect as possible. I also exclusively use Prusa's slicer. I am also telling you that I have ignored this issue in my prints for quite some time, but that the issue still remains even though to some lesser degree and it is time for Prusa to acknowledge that this issue exists.

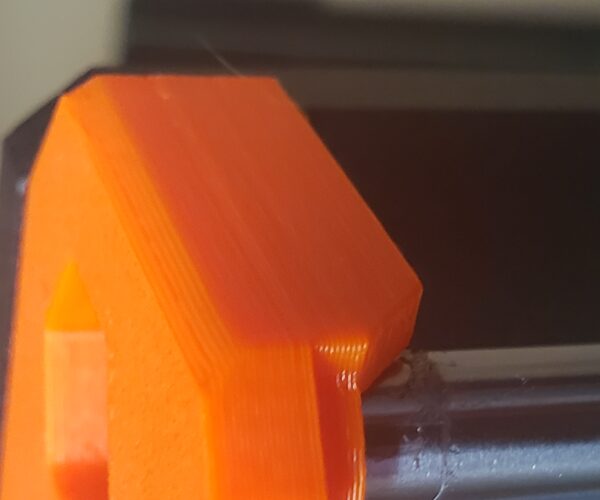

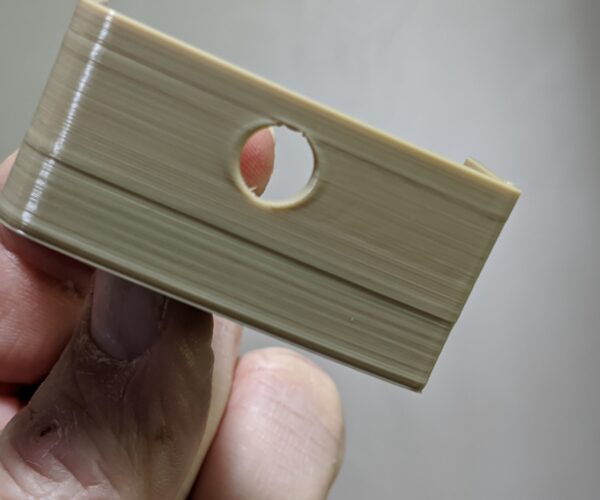

Once you notice the issue you see it everywhere... even on the printed parts that my Prusa printers are made of. See image attached. Are you suggesting that Prusa doesn't know how to calibrate their own machines for maximum effect?

I don't think that we can deny this artifact exists any longer and is potentially caused by either a slicing issue (most likely as using Cura reduces or eliminates the issue) or by firmware issues (possible, but less likely as it does transfer to other machines.)

Drew Read

RE: Buldge when print reaches "solid" layers

Bob, everyone appreciates your scientific approach to this issue, and certainly tweaking all of those things you mention can help to make it less prevalent, but let's not ignore fact that the issue still manifests even after endless calibration and tweaking.

I agree, it is an issue. I have been providing information on how to reduce the effect. My point is that there are things that influence the magnitude of the effect (e.g. wall thickness and other part design considerations). Results with default slicer profiles are also going to vary depending on how closely a user's filament and printer characteristics happen to match those defaults. Here are results of the same print done in PrusaSlicer with Prusa default profile at top and tweaked settings at bottom:

Certainly there are many Prusa users that don't want to have to spend their days tweaking and calibrating until they turn blue in the face... they simply want to print with the best printer on the market and have good results.

There are definitely some who expect toaster-like simplicity, and I'm certainly not suggesting that anybody should be forced to make adjustments. I am just pointing out to anybody that does want to address the issue that there are things that can be done simply -- and certainly not requiring calibrating until blue in the face -- that will improve results.

I am telling you right now that I have calibrated my machines (I own 4 Prusa printers currently) and I have spent the time to get things as close to perfect as possible. I also exclusively use Prusa's slicer. I am also telling you that I have ignored this issue in my prints for quite some time, but that the issue still remains even though to some lesser degree and it is time for Prusa to acknowledge that this issue exists.

I'm not sure why you're taking this tone. I've never implied that this isn't something that doesn't affect Prusa printers. Hell, I wouldn't be talking about adjusting slicer settings if that were the case. This problem, and many others, do exist. Where we may disagree is on whether things like surface inconsistencies, z-seams and other FFF printing artifacts are particularly unique to Prusa printers. Here's a print that shows the issue rather well:

The effects are particularly noticeable in light angled in from above. You can see layer lines, irregular walls corresponding to internal surfaces (the internal shelf) and features (the hole). This print very clearly suffers from a variety of defects. It was not, however, printed on a Prusa printer. Consumer-grade FFF technologies are not defect-free. I have no doubt that you are seeing degrees of these defects on your Prusa-printed parts. I have no doubt that I'll see the same effects with some variation on my Sidewinder, or on any complex parts printed with consumer-grade FFF technology. My goal is to identify techniques that might reduce the visual effects to a point that is acceptable to many users. If those results aren't acceptable to you, I have no concerns if you want to try another printer or slicer. I have done both myself... though not for these reasons.

Once you notice the issue you see it everywhere... even on the printed parts that my Prusa printers are made of. See image attached. Are you suggesting that Prusa doesn't know how to calibrate their own machines for maximum effect?

Again, I'm not sure why you're using this tone. Yes, I see these effects on FFF printed parts. I wouldn't be suggesting settings for PrusaSlicer otherwise.

I don't think that we can deny this artifact exists any longer and is potentially caused by either a slicing issue (most likely as using Cura reduces or eliminates the issue) or by firmware issues (possible, but less likely as it does transfer to other machines.)

The artifact is the result of the FFF printing process, undeniably. It can be mitigated by slicer settings. Different slicers will require different settings. Case in point:

These prints were all done using similar though not identical settings using the same filament. Some were printed on a Prusa i3 Mk3, others were printed on an Artillery Sidewinder X1. Most were sliced using PrusaSlicer, but some were sliced using default or widely available profiles for Simplify 3D or Cura. I don't think anybody will disagree that the issue with external wall consistency is present in all of these prints. I certainly see perceptible differences that can be attributed to some straightforward slicer settings and calibration effort. I also don't feel that simply the selection of slicer or printer is the biggest factor affecting print quality, and that some tuning is beneficial for any printer, slicer and filament combination.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

[...] But I would love it if it is a slicer setting issue or a tuning issue.

try making a cylinder 150mm by 20mm and shell to 5mm

Use 5 top layers 4 bottom and whatever perimeters and infill you usually use. Print at 0.2 with a 0.4 nozzle.

You can stop the print at 10mm as it’s usually quite obvious.

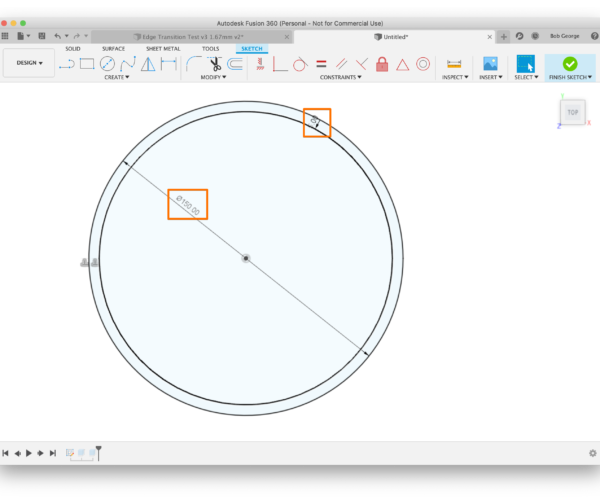

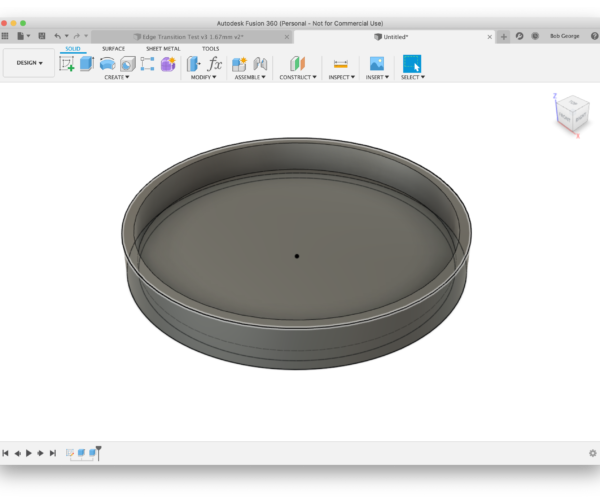

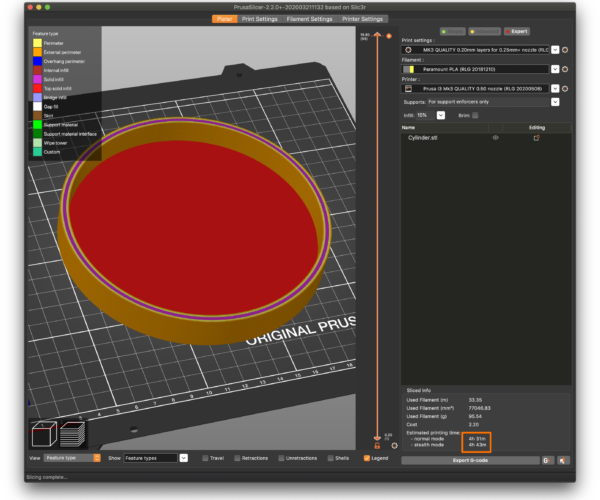

Just to make sure I've understood correctly, I created a part based on a cylinder with 150mm diameter and 5mm thick walls:

I extruded the floor 5mm to be consistent with the walls, and extruded the walls a further 15mm for a total height of 20mm:

I sliced the part using 5 top layers 4 bottom layers, 3 perimeters and 15% infill. Print at 0.2 with a 0.4 nozzle.

I'm game for testing, but unfortunately this is a 4+ hour print. If this is more-or-less what you're after, I'll work up a reduced version that will print more quickly for testing and upload it so you can verify it is still producing major defects. Does this sound like what you're after?

As I said before I thought I had this solved but then I made a triangle shelled to 5mm and the line appeared all the way through and onto a solid print on the plate at the height of the internal floor of the triangle. If I don’t print top layers then the issue never happens.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

Easy 1-2-3 to optimize for this ...

1: Detect Thin Walls.

2: Slow down print speeds to something nominal (not necessarily slow).

3: Minimize speed variation (e.g., minimize filament cooling adjustments).

4: Control seam positioning.

Doing these yields this level of improvement:

RE: Buldge when print reaches "solid" layers

I agree, it is an issue.

Bob, that is where this conversation could have stopped about 9 pages ago. I appreciate the effort you tried to put into fixing the issue with calibrations, but the fact of the matter is it simply doesn't fix the problem.

I also agree 100% that you should learn to calibrate your machines to the best of your ability, and that calibration can help to mitigate issues and potentially help to make them less pronounced. Calibration also ensures you are getting the best prints you can from your machine.

Unfortunately calibration doesn't fix the issue it helps to mask it in this case.

I'm sorry that you feel that my "tone" is terse or whatever, but in all honesty I stopped trying to infer someone's "tone" from typed word about 25 years ago. It can't be done.

Drew Read

RE: Buldge when print reaches "solid" layers

Doing these yields this level of improvement:

There may be "levels of improvement", but the issue still exists. These tweaks don't fix it... they help to mask it.

The problem needs to be investigated and fixed at the software level.

Drew Read

RE: Buldge when print reaches "solid" layers

Bob, that is where this conversation could have stopped about 9 pages ago. I appreciate the effort you tried to put into fixing the issue with calibrations, but the fact of the matter is it simply doesn't fix the problem.

I think that may be where you lost interest -- fair enough -- but there are many folks who do wish to get as good a level of finish as they can. My efforts here are on their behalf, not to try to convert anybody or deny that there's an issue. Calibration and fully understanding the slicer settings can make a big difference, often making the difference between success and failure for an individual user.

[...] Unfortunately calibration doesn't fix the issue it helps to mask it in this case.

That will be the case with any FFF printer available in the consumer space, but yes I agree. Everything we do in settings -- z-seam placement, retraction, z-lift -- is working around shortcomings of FFF printed parts. What I am trying to do is develop base settings that reduce the amount of "chasing the needle" I often see when people are unsatisfied with the results.

I'm sorry that you feel that my "tone" is terse or whatever, but in all honesty I stopped trying to infer someone's "tone" from typed word about 25 years ago. It can't be done.

I'll take you at your word then and not mince words. I feel that you are misconstruing and mis-stating my position. I have never contended that consumer grade FFF printers from Prusa or any other manufacturer produce prints that do not exhibit these characteristics. By using the phrase "Are you suggesting that Prusa doesn't know how to calibrate their own machines for maximum effect?" you turned this from a purely technical discussion to questioning my position based on something I never suggested.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

There may be "levels of improvement", but the issue still exists. These tweaks don't fix it... they help to mask it.

The problem needs to be investigated and fixed at the software level.

I believe that has been done and the result is resin printing. FFF printing has limitations. If you need better results, injection molding, different 3D printing technology or machining may be required.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Buldge when print reaches "solid" layers

... These tweaks don't fix it... they help to mask it.

The "problem" isn't a problem, it is a side effect of the technology, and it can't be fixed. And no - the measures I stated do not mask the issue, they reduce it.

If you think your $1,000 printer should be flawless, you probably bought into hype. You need to rethink your purchase strategy, ask for a refund, and consider purchasing a professional printer. And if you ever do find one that warrants flawless dimensionally accurate print (whatever that means), buy it.

RE: Buldge when print reaches "solid" layers

... These tweaks don't fix it... they help to mask it.

The "problem" isn't a problem, it is a side effect of the technology, and it can't be fixed. And no - the measures I stated do not mask the issue, they reduce it.

If you think your $1,000 printer should be flawless, you probably bought into hype. You need to rethink your purchase strategy, ask for a refund, and consider purchasing a professional printer. And if you ever do find one that warrants flawless dimensionally accurate print (whatever that means), buy it.

A "side effect of the technology" with the Prusa?

My other printer (Qidi) does not suffer from this issue and apart from bed leveling I have done nothing to it. I was on the fence for a long time about which second printer I wanted and I came very close to buying the Qidi Max. The Qidi is not perfect but it does not suffer these issues.

RE: Buldge when print reaches "solid" layers

A "side effect of the technology" with the Prusa?

My other printer (Qidi) does not suffer from this issue and apart from bed leveling I have done nothing to it. I was on the fence for a long time about which second printer I wanted and I came very close to buying the Qidi Max. The Qidi is not perfect but it does not suffer these issues.

Problem solved: ask for a refund on the Prusa and buy another Qidi: it seems to be working better for you.

Also - if you don't mind, print the same part on the Qidi and Prusa, and post a detailed image of the area of concern at the same scale and part size; and also let us know the print times for both. I'm always looking for a better printer.