Blobs and lifting plaguing Hatchbox PETG print with .6 nozzle

Reposted, I think my original title may not have been clear enough to pass inspection.

I'm pretty new, having only printed enough to run out the roll of Prusament that came with my printer. I've been trying to print the v2 Lack Enclosure parts before moving on to bigger projects but, big surprise, I can't seem to get PETG running smoothly. I put in a .6 nozzle for speed and sturdiness of upcoming prints, I've researched dozens of sets of recommended settings, and I spent the last 2 days tweaking things and still can't get past the 3rd layer without some major failure. I'm running out of patience, so I'm turning to the forums for help.

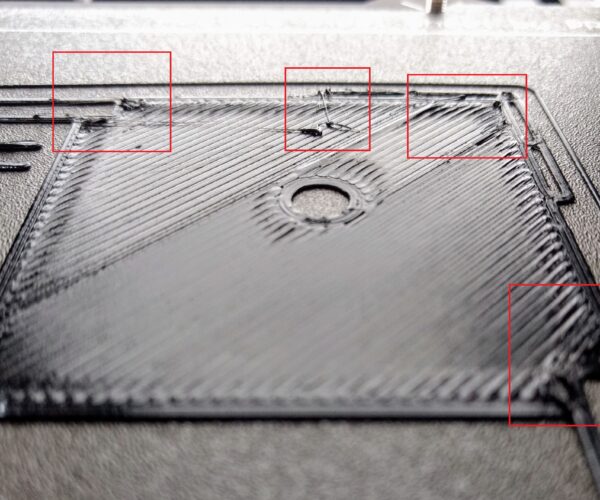

My 2 largest issues are, first, 'duck tails' when moving away from a portion of the print, where the nozzle appears to be lifting up the end of the last line laid down as it travels elsewhere. I see it most consistently around the circles for the screws in the 1st layer of the Enclosure_1 print - the circles are drawn and as the nozzle moves to start the perimeter of the box, it lifts a 'duck tail' where it pulls away from the circle. This commonly gets either pulled up or melted onto the nozzle later while drawing the bottom fill, where I then stop the print. Second, while stringing is relatively minor with my settings, globbing is not. When a line doesn't 'duck tail' at it's completion, a glob is commonly left instead. I've been worried that I'm not extruding enough, not having updated any setting other than what Prusa does when selecting the .6 nozzle config, but then I get these layer-wrecking globs at the end of lines which make me wonder whether I need to extrude less. Pictures of both are below.

Possibly also worth mentioning is that the filament semi-frequently *pops* while extruding. I thought that might be due to moisture, but the spool was just opened for the first time 2 days ago, and the humidity in my home is not very high.

Settings: Prusa i3 MK3s, Prusa textured steel sheet wiped with Windex, 0.6mm E3D nozzle, Live Z Adjust: -1.1mm, Hatchbox brand black PETG filament.

Print - Layers: First Layer: 0.45mm, Other Layers: 0.3mm, All 'Quality' settings enabled, Seam Position: Random

Print - Speed: First Layer: 15mm/s, Acceleration: All individuals set to 0 and Default set to 300mm/s2

Filament - Filament: Extruder Temps First Layer: 240, Other Layers: 250, Bed Temp First Layer: 95, Other layers: 90

Filament - Cooling: Keep Fan On: OFF, Auto-Cooling: ON, Fan Speeds: 0-70, Bridge Span Fan: 50%, Disable Fan for First 3 Layers

Filament - Override: Retract Length: 1.4mm, Lift Z: 0.6mm

Printer - Extruder: Nozzle: .6mm, Layer Height Min-Max: 0.15-0.4

Any suggestions would be greatly appreciated. Thanks!

RE: Blobs and lifting plaguing Hatchbox PETG print with .6 nozzle

First glance you are overextruding and have layer one a bit thick. Regarding the string, that coincides with the popping sounds. Surprised you aren't hearing sizzling, too. The pop and sizzle is PETG has absorbed water and you are boiling it off as you print.

You'll need to dry the filament before printing.

RE: Blobs and lifting plaguing Hatchbox PETG print with .6 nozzle

I tried it again this morning, after baking the filament for a couple of hours. Aside from causing the label to fall of of the spool, it was beneficial. I heard no more popping or crackling; odd because it was freshly opened, but so much for quality control.

I turned the extrusion down to .95 and printed at 230 for the first layer and it started out well other than being a bit thin. I moved the Live Z a bit lower to counter, but it still pulled the support base off of the plate as it moved away from it. I tried a second time with extrusion rate back at 1 and the original Live Z and then it failed while drawing the initial outline 😫

RE: Blobs and lifting plaguing Hatchbox PETG print with .6 nozzle

The other issue is bed adhesion is driven mostly by how clean the print sheet is. With PETG, the issue should not be as bad on the PC sheet as PLA is, but you want to make sure the sheet is clean. Try doing a serious alcohol clean to start, and print a test piece to see how well the PET is sticking (no release agent - keep the part small - freeze for 30 minutes to release if it actually grabs well).

Also - a couple hours may not be long enough. PrintDry recommends 65c/150f for >3 hours. It's been my experience these are absolute minimum times for even marginally damp filament. The fact you don't hear sizzling now is an indication you are on the right track - so thumbs up there.