Bevel gears are printing with blobs and PrusaSlicer is filling the hole

Hello,

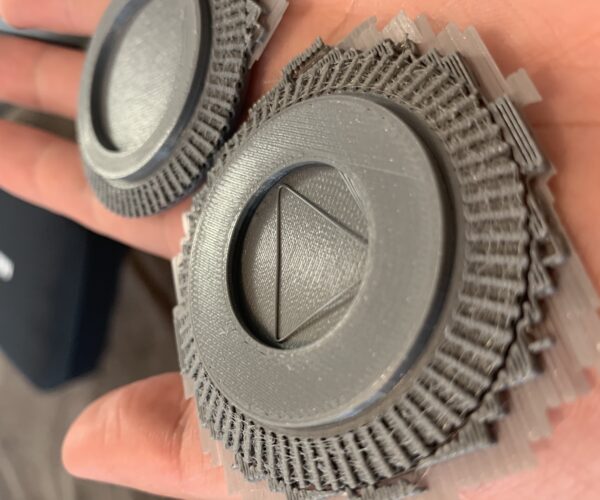

I've been trying to print out these bevel gears for a school project. The problem is the Slicer will fill in the holes and the bevel gear print out are unusable. I use the Slicer to repair the files and it still fills the hole. Please let me know what I can do or if someone call help me make the file printable.

Thank you!

Here is the zip folder of the files (Both the batch file of the gears and the individual): 3d

RE: Bevel gears are printing with blobs and PrusaSlicer is filling the hole

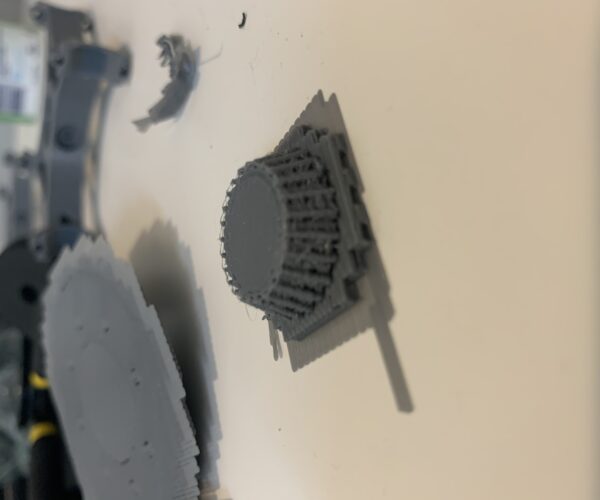

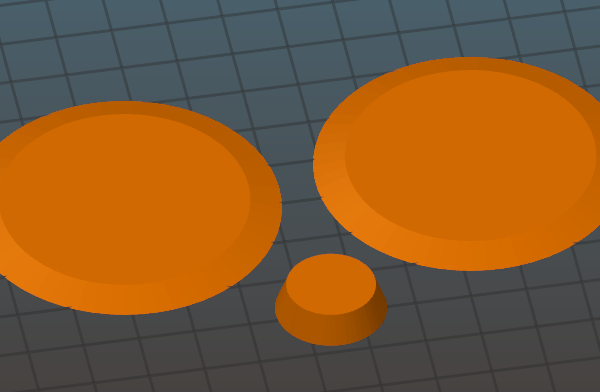

Here's another view showing your model -- it has stuff in the center holes. Correct the model before you try printing it - a repair tool can fix some minor vector errors (non-zeros, face normals, simple issues), but they do not repair parts that are simply not properly designed.

RE: Bevel gears are printing with blobs and PrusaSlicer is filling the hole

Hello devonpamilar,

How were the objects in the STL files created? Many of your object issues below seem to be due to the actual object creation process followed.

- All the STL files show issues with an extra thin wall about halfway up the tooth profile of the gears.

- The raw "Straight Bevel Pinion Gear.STL" is non-manifold with my PrusaSlicer 2.2.0 reporting that it had autocorrected 23520 reversed facets.

That is surfaces (triangles) that are facing into inside of the object instead of outside the object. This may be an issue with the software you used or the process you used when creating this object.

- The central hole on the at least both the "Straight Bevel Pinion Gear.STL" and the "Straight Bevel Involute Gear Output.STL" have unsupported overhangs where the hole radius has suddenly decreased leading to at least two unsupported perimeters. Suspect that your slicer trying to automatically compensate for this is the part cause your filled central holes in these two objects.

For each overhang in a central hole manually add a single layer thick horizontal wall to completely cover the hole; the slicer should handle that correctly BUT you will then have to physically remove that printed wall from the actual final 3d print.

Please note that your problem "Straight Bevel Pinion Gear.STL" has two such overhangs in its central hole.I'm unsure of why the third object "Straight Bevel Gear 1.STL" is filling its central hole from 2.50mm upwards; the slicer seems to be handling the bottom bevelled end correctly before it tries to print two unsupported overhang perimeters and the bridge layer. Suspect that this is also due to problems in the source STL file creation.

RE: Bevel gears are printing with blobs and PrusaSlicer is filling the hole

Note - if your using the OpenSCAD difference() function to create the holes you need to remember to slightly overlap the object being subtracted over the original object. There must be a greater than zero overlap or OpenSCAD will leave an "invisible" zero thick wall that will appear in the final STL file to cause print issues.

RE: Bevel gears are printing with blobs and PrusaSlicer is filling the hole

@devonpamilar

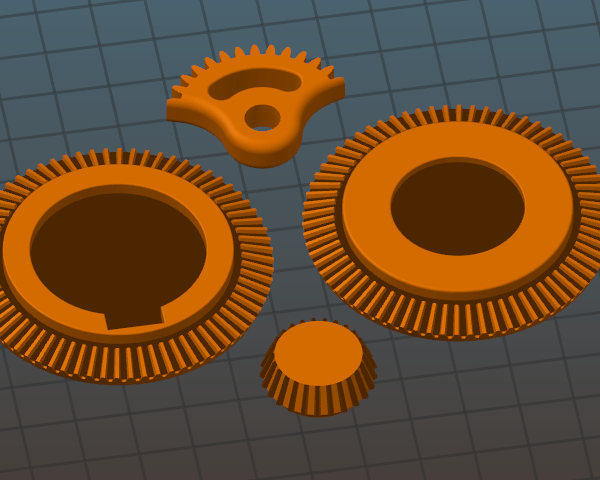

I know I'm a bit late to this post But I've looked over your .STL models and didn't find any real problems with them. it seems that you may have exported the modifier meshes with the .STL's and they were mistaken for part of the model as reported by Tim, however the models are fine and need no modification to print them.

Straight Bevel Involute Gear Output.STL & Straight Bevel Gear 1.STL can be printed together, Straight Bevel Involute Gear Output.STL will need some support but only around the thin rim towards the top of the gear, use a support setting of everywhere with an overhang threshold of 25 this will support only the rim and not try to support the holes in the underside as they wont need any. Straight Bevel Gear 1.STL needs no support, as for Straight Bevel Pinion Gear.STL it will need support on the inner ring and the thin rim around the top. I would tend to print this part by itself at a layer height not less then 0.1 its a small part and looses detail beyond that if you must use automatic supports for this part then I'm also going to recommend and overhang threshold of 25 however, if you have modeling skills I'm going to suggest that you simply model your own supports for this part as they would be more easily removed at this scale. I believe the stringing that appears in your photos could be caused by moisture in the filament but it can be caused by several factors aside from that for example trying to print to fast. I might suggest ticking the (avoid crossing perimeters) box and see if that helps to clean things up a bit

Don't forget to remove those modifier meshes you don't need them for these prints

Good Luck

The Filament Whisperer

RE: Bevel gears are printing with blobs and PrusaSlicer is filling the hole

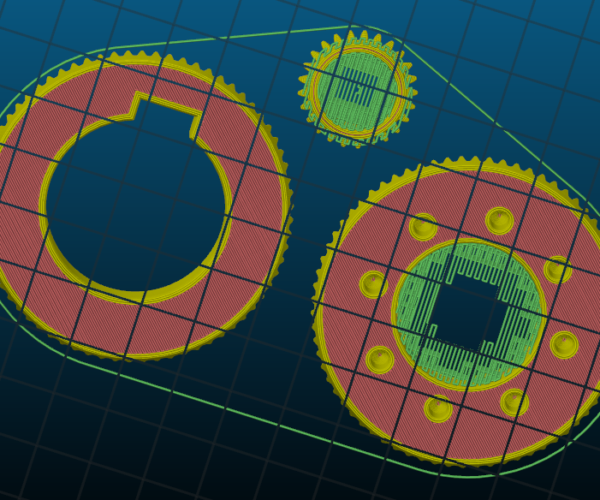

Well since I couldn't go out Trick or Treating I decided to print these gears instead, as it happens after slicing the 4 gears in the file at 0.1 with 20% infill for ASA, I needed 16.86g of filament and I just happen to have a roll with 17g left on it 😎 .

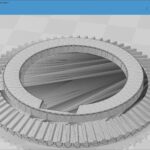

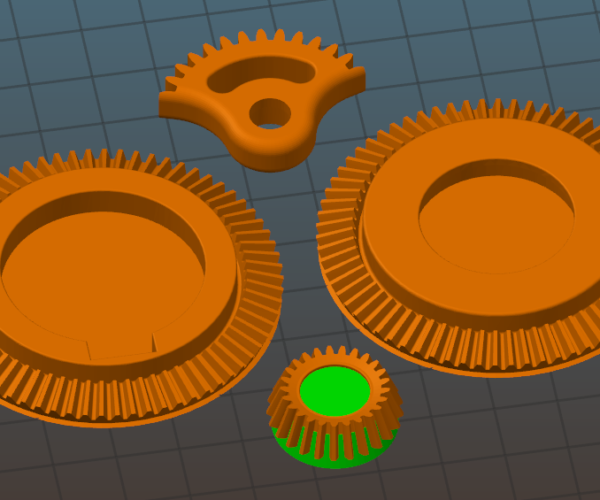

These are the files as provided in the batch3.3mf note the dark brown areas in the image above, they denote a different mesh that I assume was exported to be a modifier mesh for use with the support settings for the gears?

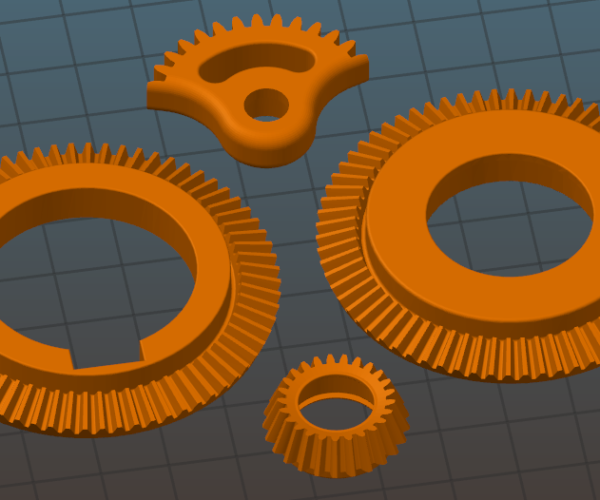

Anyway after Splitting them they look like this, then you can select and delete the extra meshes.

I included the image below to show the extra mesh.

I mentioned using supports with an overhang threshold of 25 in my previous post, however I found 15 to be even better after fine tuning.

I'm printing the Toroid Shifting Gear also, however it has some design related issues and I had to play with it a bit and didn't have it ready at the time I took the screen shots.

I hope this helps,

Good luck

The Filament Whisperer