Banding on slopped cylindrical surface and volumetric flow rate.

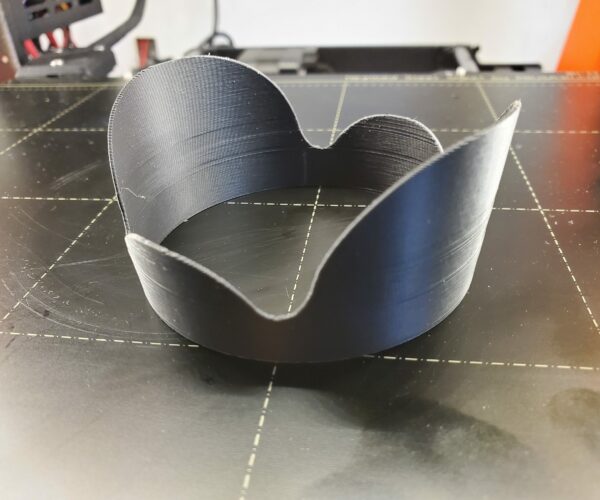

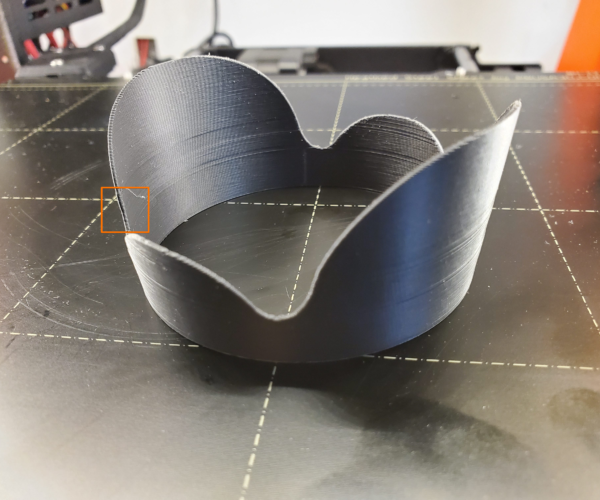

Hi I'm trying to print a camera lens hood but getting uneven banding on the middle section of the print.

At first I thought that I'm having some sort of layer shift, but then I realised that this is not happening on any of my regular cylindrical prints, only on this kind of sloped shape.

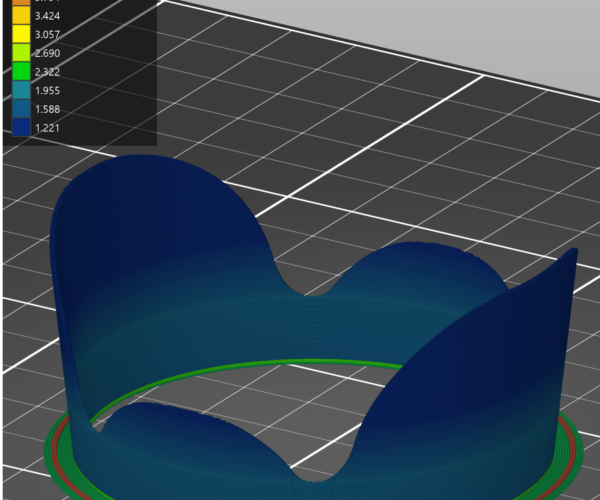

I then went back to Prusaslicer and looked at the volumetric flow rate view and I found that the banding happens when the flow rating changes.

I don't know what's causing these, and I don't know whether volumetric flow rate changes are the cause of the banding. Can someone please take a look at my project file and see what you can find out?

RE: Banding on slopped cylindrical surface and volumetric flow rate.

It would be helpful to get a look at the print and your settings. Can you save a 3MF project file, zip it up and upload it here as an attachment?

My initial suggestion is to slow down to 50% and see if there's any improvement. If so, you can fix the issue with slicer settings. Layer heights are important on slopes. You might try reducing layer height or using the automatic variable layer height feature.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Banding on slopped cylindrical surface and volumetric flow rate.

Hmm, I thought I did attach the file. let me try again.

Edit: I don't know what I'm doing wrong. I attached the file but it's not uploaded... it says file type not allowed. 3mf file type is not allowed?

Edit again. Sorry I didn't see that I need to zip the file.

RE: Banding on slopped cylindrical surface and volumetric flow rate.

If external perimeter speed is set to 15mm/s, speeds and flow are more consistent. It might be worth a shot to see if that helps.

Prints with thin walls and transitions can be a challenge. Notice how the flow changes above the transition in your print.

This is common if the nozzle changes direction at one layer, or there is a change in the surface (e.g. change from sparse to solid infill), overhang or layer print time.

Slowing down helps with evening flow rates across surface transitions. If that helps, you might try calibrating your filament extruder multiplier or linear advance settings to see if you can get the flow to even out at higher speeds.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Banding on slopped cylindrical surface and volumetric flow rate.

@bobstro

Alright, I'll try all your suggestions. Thank you so much.

RE: Banding on slopped cylindrical surface and volumetric flow rate.

I tried several variations and still am getting the uneven layers above the notches. I believe the thin walls contribute to this problem. Is there any chance you can make the walls a bit thicker? This might help even out extrusion as the nozzle is moved around at different speeds at different heights.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Banding on slopped cylindrical surface and volumetric flow rate.

@bobstro

Hey, I tried 15mm/s and it didn't improve much at all. I've just calibrated extruder multiplier and I'm trying it again. I think you are right that there isn't much I can do with such thin walls. I can clearly see that everytime nozzle changes direction the banding appears. I guess it's time to rethink the design. Thanks for your effort.

RE: Banding on slopped cylindrical surface and volumetric flow rate.

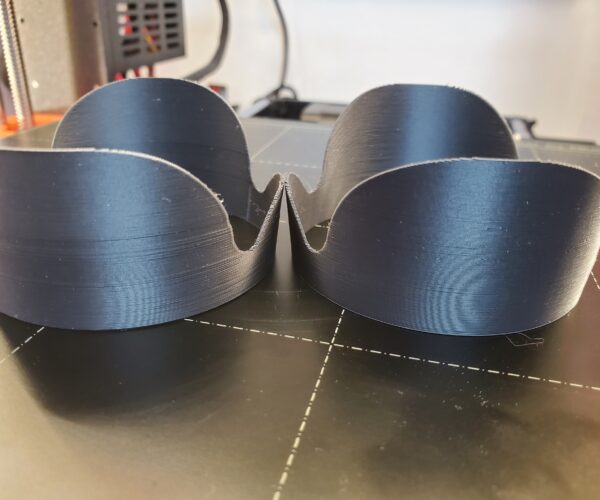

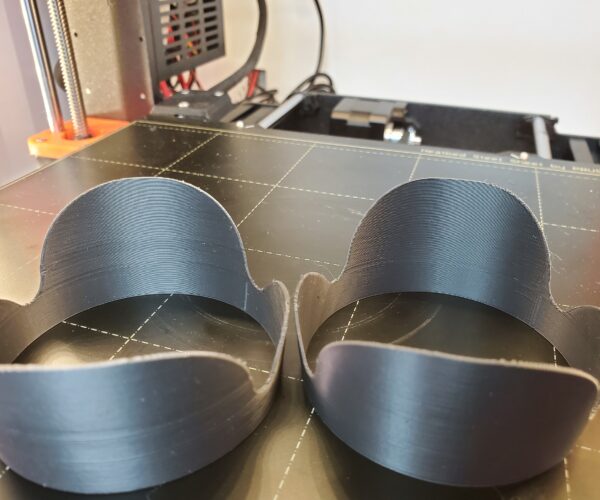

Alright, after calibrating extrusion multiplier, the result has improved greatly. Although not perfect, the banding is much less visible. In these attached photos, on the left hand side is the result of changing perimeter speed to 15mm/s and no other change. On the right hand side is the result of calibration and slower speed at 15mm/s. I'm happy with the improvements especially on the outside surface of the print.

I'll now try to print faster at 20-30mm/s and see what the limit is for this material and print profile.