Another PETG question

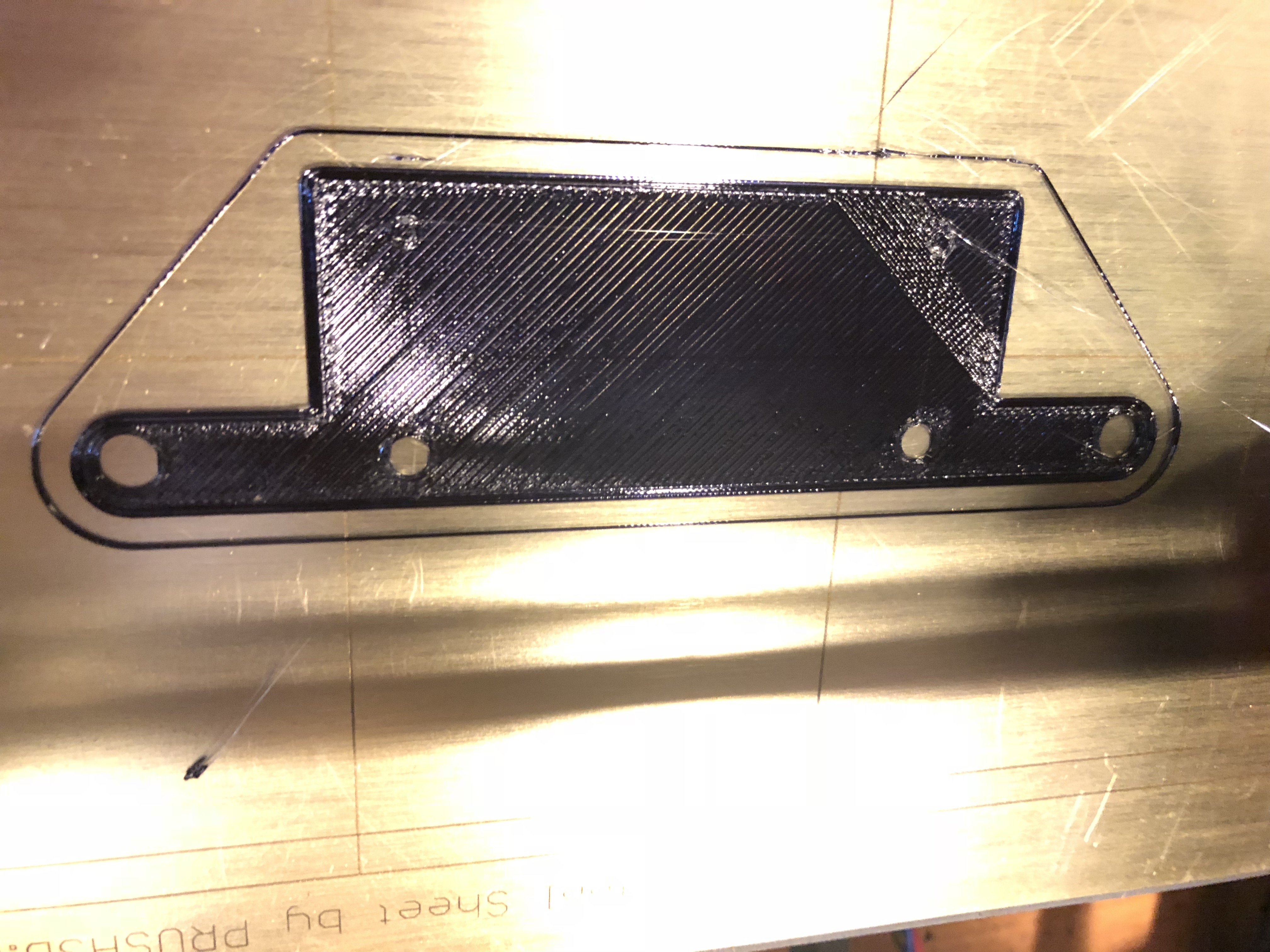

I have searched this forum and have tried almost all suggestions I'm capable of. I'm trying to print SUNLU PETG and the first layer is horrible. The final product is really rough. I am using an assembled MK3 and using PrusaControl to slice. I've set it to Generic PET and Prusa PET and the results are equal. I have been told that live Z should not be adjusted between PLA and PETG but should be the same. I have gone slow or fast, cold or hot and still the results have not improved.

First layer:

Nozzle: 235

Bed: 85

Susbsequent layers:

Nozzle: 240

Bed: 85

Manufacture of PETG recommends 230-260.

I started to use Slic3r Prusa edition and adjusting my parameters, but found I would get layer shifting. Joan mentioned in another post that Slic3r could be corrupting the file and I've stuck with PrusaControl with no layer shifting, just rough parts.

I also have a bridge that isn't working too well. The span is approx. 75mm. I can print in PLA without troubles, just can't get the darn PETG to print. Please assist.

Re: Another PETG question

I have been told that live Z should not be adjusted between PLA and PETG but should be the same.

Just to address one point, you DO need to adjust the Z between PLA and PETG. Your print looks like it has gaps suggesting that the fist layer Z is too high. While I print 99.9999% PETG , I do have occasion to use up the Pruse PLA that came with the printer. When I do I have to raise the Z for the PLA, then lower it back down for PETG. I simply do it via Live Adjust.

PETG takes a little more finess to dial it in properly. Once you do, as I think I have, it is a great print medium.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

Re: Another PETG question

With regards to the first layer on PETG a Z offset in the slicer of 0.15 to 0.2mm is required. To counter this for proper first layer fusing a first layer height of 0.3mm is needed.

With regards bridging 75mm seems like a long distance. You may need to up the part fan speed on bridges the default in Slic3r it is at 50% for PETG. Sunlu PETG is not as forgiving as some of the others so it really needs to be dialled in well to print properly. However once tuned in Sunlu is good for prototyping and mechanical parts in PETG. I do most of my prototyping for models in their PLA+.

Regards,

Martin

Martin Wolfe

Re: Another PETG question

I have never run a separate Z offset for PETG- theoretically you shouldn't ever need it unless you are printing onto a foreign surface (glass).

That first layer is definitely too far away... you might want to look into temperature calibrating your PINDA if it is that different between PLA and PETG- Mine was just like that until after calibration, now it's great no matter the bed temp/ material

Anything can be made better

https://www.myminifactory.com/users/Joe%20Prints

Re: Another PETG question

The reason for the separate offset for PETG is that it is very sticky and tends to stick to the nozzle as a result. However as it is so sticky it does not need any squishing to bind the layers together.

Regards,

Martin

Martin Wolfe

Re: Another PETG question

Hi Jared,

Sorry to hear you're also having problems printing your first layer in PETG.

You will need to adjust your Live Z value between PLA and PETG. Martin has had good success with inserting a Z offset in Slic3r, but unfortunately this won't work for everyone. Based on the photos you provided, I would agree that your nozzle is simply too high. I would suggest adjusting your Live Z to bring the nozzle closer to the bed and watch as the individual lines are laid down. If you try using Slic3r again, I would also recommend increasing your first layer to 0.3 mm. Are your fans running for the first layer? If so, try turning them off. I'm using filaments.ca PETG and found that I had to increase the temperature from 230 to 255 to begin getting better results.

gdo's PETG settings really helped to improve the quality of my first layer. The nice thing about Slic3r is that you can save multiple profiles, which helps to systematically eliminate possible issues. Your object is relatively small, so it might just take some more trial and error printing to see what helps. I'm in week 2 of trying to improve my first layer in PETG, but still haven't found the solution.

Cheers,

Adam

Re: Another PETG question

PETG takes a little more finess to dial it in properly. Once you do, as I think I have, it is a great print medium.

[/quote]

Can you help me understand your workflow printing with PETG? How do you start out? Do you have a calibration print that you perform to get the first layer just right?

My workflow for PLA was to print a calibration square and make sure the live Z was adjusted perfectly so the square would come out uniform and bonded together strong. I tried to do something similar for PETG and my square turned out great, but when I went to print an object, it was horrible!!! So, there's a lot I'm missing. I was trying to print just from PrusaControl, but it seems like I need to slice with Slic3r and adjust my parameters and not let Prusa Control dictate the parameters.

Here's the calibration square I was referring to: https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html

Re: Another PETG question

When I was tuning PETG I was working with a real print and watching that first layer. Once I had seen enough I just aborted the print made a tweak and tried again. One thing I forgot to say in my earlier post is that the first layer for PETG needs to be printed ridiculously slow.

First Layer Rigid Ink PETG stock nozzle and block with sock, 230C at 10mm/s

First Layer Rigid Ink PETG plated copper nozzle and plated copper block with sock, 220C at 7mm/s

Although the plated copper nozzle and block has a higher max volumetric flow for PETG the first layer is slower. It gains on the infill speed.

Regards,

Martin

Martin Wolfe

Re: Another PETG question

Martin,

THANK YOU! I'll start with the first layer going super slow and just print the first layer of the part I'm trying to print. I also understand it needs to print super slow. I'll start super slow at 10mm/s, keep the nozzle at 230C and bed at (I believe) at 80C.

I assume it needs to print flat and smooth like I was printing my PLA square?

Rigid Ink is SUPER expensive in the US. I've got access to Hatchbox, eSUN, 3D Solutech, InLAND, PRILINE, and SUNLU. Any recommendations?

Re: Another PETG question

It won't be as flat as PLA but it will be smooth. It should look like tha flat top layer from a PLA print. Unfortunately I can't help you on premium filament suppliers in the US but I have hear a lot of people swear by Hatchbox and eSUN. Although I believe eSun is one of the cheep filaments. Hatchbox however has good reviews.

Regards,

Martin

Martin Wolfe

Re: Another PETG question

[...] Rigid Ink is SUPER expensive in the US. I've got access to Hatchbox, eSUN, 3D Solutech, InLAND, PRILINE, and SUNLU. Any recommendations?

Inland is good stuff, not to mention cheap. I've tried their PLA and PETG and both printed as well as the more expensive stuff. If you have a Microcenter nearby, it's the winner for basic filament.

I've tried Gizmo Dorks, Paramount, Rigid.ink and a few other samples. No major difference between them in my experience. I buy basic PLA based solely on color choice. For non-functional and test prints, any of the more known PLA brands seem to be fine. I'm limiting more expensive filament purchases to specialty filled and materials.

For PETG, 3DXTech orange is a great match for Prusa, and an interesting matte color. AIO Robotics and Inland worked well.

Re: Another PETG question

Rigid Ink is SUPER expensive in the US. I've got access to Hatchbox, eSUN, 3D Solutech, InLAND, PRILINE, and SUNLU. Any recommendations?

For PETG, 3D Solutech and Inland are excellent, inexpensive filaments. For PLA, Inland, 3D Solutech, Hatchbox, Zyltech and Coex are my goto's. I buy quite a bit of Zyltech and Coex on CyberMonday as they are usually about 40% - 50% off then with no limits on the quantity.

Re: Another PETG question

Thank you Richard! Especially having state-side experience. I love the idea of sharing information world-wide, but there are things like this that is location specific. Thank you tons!

Re: Another PETG question

If you have your Live Z set correctly with a clean bed, you shouldn't have to slow down the first layer that much. My first layer speed is set to 40 mm/s and I've never had issues with it. I haven't printed much with PLA, but I'm pretty sure the Live Z has to be different. With PLA you want to squish it into the bed to make it stick, you can't do that with PETG.

When I have to set the Live Z I print a 30x30 square in the center of the bed with a large skirt around it. While it's printing the skirt I eyeball it until the nozzle about even with the top of the filament it's laying down. Then, when it's doing the infill on the square I bring it down until I start to see filament building up on the nozzle and raise it a little at a time until the buildup stops (I can use my spatula thing to press the buildup into the print to clean it off). The result should be a flat first layer without any gaps between the lines. If you're getting waves or rough areas then it's too close, gaps between the lines or your corners drag out of place and you're too far away.

First Layer: 245C/80C, 40 mm/s

Other Layers: 240C/90C, 80mm/s (although I've gone up to 120mm/s with a bit of quality loss, no fan except for when the layer time is less than 20s and bridging.)

I use a bed temp of 90C now because I used to get a small bit of warping with large objects. I also have an enclosure now that keeps the ambient temp around 30C.

As for bridging, I try my best to avoid it in my designs. PETG is very saggy and I don't think I've ever really tried to bridge anything more than 30-40mm. If you can, you'd probably have better luck putting some thin supports every 15mm or so.

Re: Another PETG question

When I was tuning PETG I was working with a real print and watching that first layer. Once I had seen enough I just aborted the print made a tweak and tried again. One thing I forgot to say in my earlier post is that the first layer for PETG needs to be printed ridiculously slow.

First Layer Rigid Ink PETG stock nozzle and block with sock, 230C at 10mm/s

First Layer Rigid Ink PETG plated copper nozzle and plated copper block with sock, 220C at 7mm/s

Although the plated copper nozzle and block has a higher max volumetric flow for PETG the first layer is slower. It gains on the infill speed.

I have done some retuning on PETG with the plated nozzle without a sock. I increased my Z offset even further and this eliminated the dragging completely. So I then upped the first layer speed. I am now printing PETG first layer at 0.3mm Z offset and 30mm/s. Basically I am now printing my PETG first layer at the default Slic3r speed as set by Prusa. 🙂

So revising my earlier conclusion the plated copper nozzle and block combination prints faster than the brass nozzle and aluminium block combination.

Regards,

Martin

Martin Wolfe

Re: Another PETG question

Are you using the PETG profile created by Prusa for the Slic3r Prusa Edition?

I don't see anyone talking about fan speed here but you don't want the cooling fan running for the first few layers and when it does run you don't want to run it at full speed. If you compare PETG/PLA profile you will see what I mean.

Also for me when I started with PETG all I did was change to PETG profile, figure out what temp I needed and raised the z-axis using the live offset feature. Messed around a bit with the longer bridges by uping the retraction a bit to deal with additional stringing

Re: Another PETG question

Christopher,

Thank you for responding! Could you expand on your post because I think you have some key nuggets of knowledge here and I need to clarify. So, once I get the calibration dialed in, I need to likely play around with fan speed on the bridge (especially the bridge of about 70 mm). Are you thinking I should go slow over the bridge, but increase my fan speed?

I am/was using the PETG profile from Slic3r Prusa Edition, but have made changes from other suggestions from members.

Re: Another PETG question

Christopher,

Thank you for responding! Could you expand on your post because I think you have some key nuggets of knowledge here and I need to clarify. So, once I get the calibration dialed in, I need to likely play around with fan speed on the bridge (especially the bridge of about 70 mm). Are you thinking I should go slow over the bridge, but increase my fan speed?

I am/was using the PETG profile from Slic3r Prusa Edition, but have made changes from other suggestions from members.

Hey. This is a pretty good video from Tom at Toms3d: https://toms3d.org/2018/02/05/things-know-petg goes over, fan temp, stringing, retraction

For long bridges would try 30mm-60mm with greater fan speed(70%+)

Re: Another PETG question

I am/was using the PETG profile from Slic3r Prusa Edition, but have made changes from other suggestions from members.

There are few other profiles in the forums you could try, including one I posted. I was getting a lot of stringing with the stock PR profile.

Re: Another PETG question

It won't be as flat as PLA but it will be smooth. It should look like tha flat top layer from a PLA print. Unfortunately I can't help you on premium filament suppliers in the US but I have hear a lot of people swear by Hatchbox and eSUN. Although I believe eSun is one of the cheep filaments. Hatchbox however has good reviews.

Regards,

Martin

i wouldn 't characterize esun as cheap. I find their pla/abs/petg to be very nice quality. in the US you can either find them on amazon or https://www.intservo.com . if you register on https://www.xyzfabs.com/ you can get a 25% off multiuse coupon. unlike amazon you do pay shipping but if buying over 1 spool at a time it is cheaper.