A waterproof 3D print

Hi,

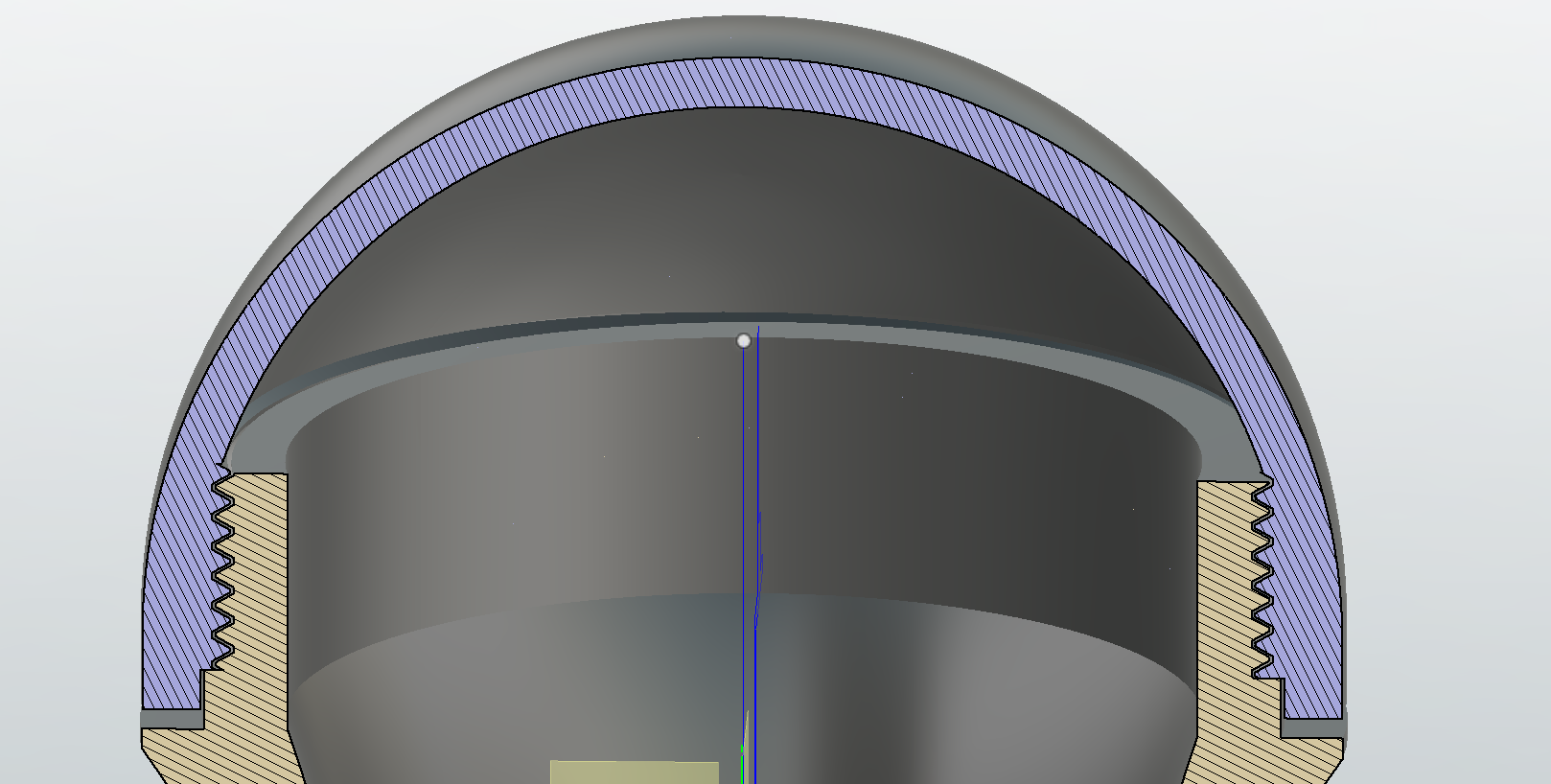

I am trying to print a waterproof enclosure, for a pool temperature sensor (see attached).

The objective is to use a waterproof ds18b20 (like here https://www.aliexpress.com/item/1pcs-DS18B20-Stainless-steel-package-1-meters-waterproof-DS18b20-temperature-probe-temperature-sensor-18B20/32656021988.html?spm=2114.search0104.3.1.6e874ff0DBWR5U&ws_ab_test=searchweb0_0,searchweb201602_7_10065_10068_319_10892_317_10696_10084_453_454_10083_10618_10304_10307_10820_10821_537_10302_536_10843_10059_10884_10887_321_322_10103,searchweb201603_54,ppcSwitch_0&algo_expid=1804eb59-933d-4542-9a17-22a78de6f7f3-0&algo_pvid=1804eb59-933d-4542-9a17-22a78de6f7f3 ).

This sensor is inserted in the hole at the lower part, and sealed with a lip seal, pressed by the plastic part in light green on the schema.

So far it is working well.

On the upper part, the head is screwed, and should pinch the torus joint (the torus joint is red on the schema)

So far, this joint is failling and some water is able to flow inside the body : I assume it is because the upper layers are never clearly flat, contrary to the lower layers...

Do you have any idea how I could achieve this sealing ?

Re: A waterproof 3D print

How are you printing that orange dome at the top? If you print it as shown, then the surface that is supposed to seal against the o-ring (torus seal) is overhanging and will not be as smooth as possible.

One suggestion would be to redesign the orange part to be more like a bottle cap, with a flat top surface. So then you could print it upside-down and the part of the print that comes in contact with the o-ring will be smoother.

There's some tutorial material about o-ring sealing in Wikipedia https://en.wikipedia.org/wiki/O-ring .

Re: A waterproof 3D print

Hi,

Thank you.

The head (orange dome) is actually flat on the part in contact with the o-ring : this is a new design I made, I thought that it would be more efficient like that...

I attached the piece I tried : you will see the bottom face is quite flat (I printed it on kapton on my printer) ; there is some small ugly default, cause I tried multiple thing to make it waterproof... I even tried to use some acetone on it.

I would better thing the problem is more with the body upper part : this face will not be flat, as it is the top solid layer of the print...

Re: A waterproof 3D print

From the rendering you showed, I assumed that the o-ring was contained in a toroidal space between the outer lip of the cap and the inner lip of the cylinder - so the surfaces that would need to form a seal would be either the inward-facing perimeter of the cap plus the outward-facing perimeter of the cylinder,

or else the downward-facing inner rim of the cap plus the upward-facing outer rim of the cylinder.

In your pictures, neither of those configurations seems to be smooth. However, if your sealing element is more like a gasket than an o-ring, that is with a rectangular cross-section instead of a circular cross-section, then it would seem your pictured devices would work because they have smooth surfaces for that alignment.

Re: A waterproof 3D print

Yeah,

But as I said, this is not the original design... the first one (the one you can see on the pictures) is flat and there is no filet on both side (up and down)...

This is the original design :

But still it is failing... the head surface is really smooth, while the top layer of the body is not flat is it is the top layer of the print...

What do you think ?

Re: A waterproof 3D print

So what you really want is a gasket, not an o-ring seal.

To further perfect the top surface of the cylinder, I would say to create a short "ring" simulating the top of the big cylinder (at least 4 layers thick) which will print in just a few minutes, and experiment with different settings for Extrusion Multiplier, Number of Perimeters, and Top Infill Pattern. You should be able to get a surface that is quite smooth, although probably never quite as perfect as the bottom surface that's printed on a smooth bed.

Another approach to better sealing might be to find a softer material for the gasket.

And yet another approach would be to apply a thin layer of silicone sealant (RTV cement) to the top of the cylinder and put the gasket on the cylinder before the sealant cures. The gasket will be semi-permanently attached to the cylinder, but the leakage paths between the gasket and the cylinder should be sealed. You can still install and remove the cap without any problem if the silicone sealant doesn't get on the threads.

Re: A waterproof 3D print

Have you oiled/greased the ring (with something compatible with it)?

Dry o-rings can leak even with smooth mating surfaces. For example, I had a SCUBA flashlight - the manual advised to oil the o-ring (it suggested a safe formulation) monthly, to ensure a good seal. I neglected to do so, and noticed fogging on the interior of the lens - evidence that moisture was making it's way inside.

The oil/grease fills in the tiny imperfections on the ring and mating surfaces that allow water to bypass the ring. On an FDM object, these would be even more prevalent.