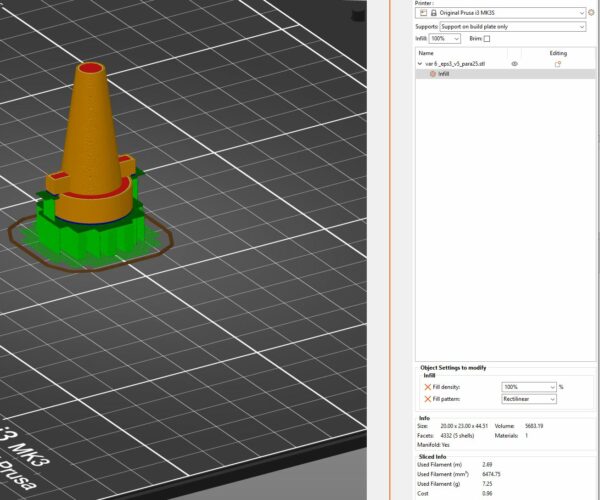

100% infill with no airgap - zero hollowness

For a very special Sat comms application I have developed a printable dielectric lens. The filament is Preperm ABS300. Now the results are already quite good and we have found it is very important to print with 100% infill. But even using Rectilinear infill pattern, there seems to be small "micro" airgaps when printed, which degrades perfromance of the lens.

Now the question is, is there any trick or tip to get an infill with zero hollowness or is the 100% infill with Rectliniear pattern already the maximum ?

Thanks

Roland

RE: 100% infill with no airgap - zero hollowness

Hi Roland,

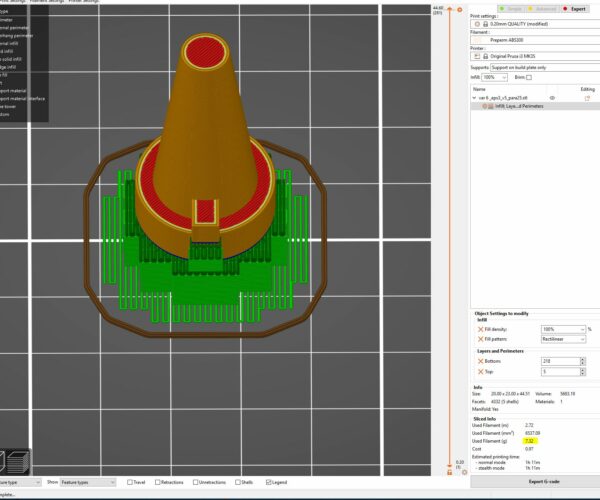

Try increasing the number of top and bottom layers, so that there is no infill at all...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: 100% infill with no airgap - zero hollowness

You could also try deliberately over extruding slightly. Another possibility is to try SuperSlicer https://github.com/supermerill/SuperSlicer/releases which is a fork and built upon Prusa Slicer so should be familiar to you in use. That has extra options and settings available. It has a couple of extra infill types like rectilinear (filled) and Concentric (filled).

RE: 100% infill with no airgap - zero hollowness

@joantabb

Thank you Joan, I changed the layers and the weight of the used filament increased slightly which is a good sign. More filament means less air 🙂

RE: 100% infill with no airgap - zero hollowness

@neophyl

Ok thank you for the tip, I will try that next. Testing the lense on the satellite dish always takes some time until we have a firm understanding and values to proof if the signal strength increased or decreased.

Much appreciated !

Roland

RE: 100% infill with no airgap - zero hollowness

For zero airgaps in the printed part you may have to think outside the box and print your part with PLA, create a mold from it from which the PLA can be burnt out then pour molten dielectric material into the remaining empty mold.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: 100% infill with no airgap - zero hollowness

@chocki

PLA is not a suitable material for a dielectric lens.

RE: 100% infill with no airgap - zero hollowness

@atomic

No but it is a suitable intermediate material to make a master part with which to then make a mold that can then be used with the appropriate material as was suggested by Chocki

RE: 100% infill with no airgap - zero hollowness

@neophyl

I have no intention to make a mold. My question was not about plastic molding. Preperm filament is already the appropriate material for our application.

@joantabb

Your tip worked quite well. Going to measure the signal noise ratio tomorrow and see if it made any difference.

Cheers

RE: 100% infill with no airgap - zero hollowness

@atomic

Good Luck

If there are still gaps, try checking the flow rate is 100%

look for a line like this in the custom end gcode

M221 S{if layer_height<0.075}100{else}95{endif}

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: 100% infill with no airgap - zero hollowness

With the help of SuperSlicer and Rectilinear filled infill plus overextrusion by a small margin I was able to measure and reproduce a slight improvement by 0.1 dB. Does not sound much but if you wanna go from 99 to 100% it gets exceptional tough.

Thanks for your help!

Roland