Y-axis crash detected....driving me nuts

On every print that I do, I get 1-3 "crash detected" messages on the Y-axis. The extruder moves up and home, then moves back to the print and resumes. The prints come out perfectly, but what happens is that the printer slows down. The screen reads less than 100% until I reset the printer.

I have checked everything in the support article. The bearing are good and packed with superlube, the smooth rods are good, the build plate slides smoothly, the motor turns smoothly, the belt test shows the tension is within range and is similar to the other 3 printers I have.

I'm simply at a loss for why these crashes are happening. If I turn off crash detection the prints come out perfect and in 3 months of continuous printing I've had no problems.

Any ideas?

RE: Y-axis crash detected....driving me nuts

Is the idler bearing clogged? Is it straight? Are the belt teeth damaged?

Cheerio,

RE: Y-axis crash detected....driving me nuts

Is the idler bearing clogged? Is it straight? Are the belt teeth damaged?

Cheerio,

As far as I can tell everything is good. The belt and pulley are fine and it looks straight to me.

RE: Y-axis crash detected....driving me nuts

@buckeyestargazer

I would not rely on the belt tension indicator on the LCD and prefer to check the tension mechanically.

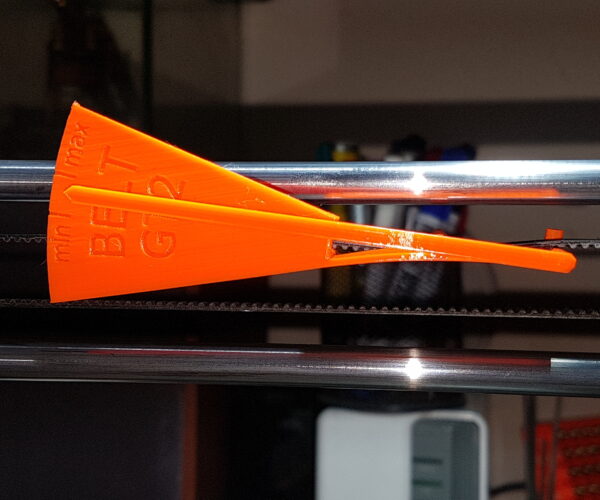

You can print yourself a simple tool for this purpose: belt-tension-meter-for-gt2-belts

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis crash detected....driving me nuts

The belt tension reported is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension. As @karl-herbert says, other things can affect mechanical resistance. So low tension and some other added resistance can, falsely, report as correct.

Alternatively, crashes can be impacts with external objects - drooping cable bundles, tools left too close etc. Or external shaking from slammed doors, teenagers kicking balls against the workbench ... that sort of thing. Are there any patterns to these crashes?

Cheerio,

RE: Y-axis crash detected....driving me nuts

@Karl

I'll try the belt tension meter when I get a chance.

@Diem

It's definitely not drooping or dragging cables or other external force. At first I thought perhaps the crashes were happening at the same Z height but I carefully watched a couple of prints and there doesn't seem to be a pattern than I can see.

The one thing I can see is that perhaps the motor pulley is too close to the motor itself. There is a gap between the motor and pulley, but not much and that might be forcing the belt a little too far to one side of the idler. Maybe it's not straight enough.

RE: Y-axis crash detected....driving me nuts

The one thing I can see is that perhaps the motor pulley is too close to the motor itself.

Check with the build manual - it is possible to fit the pulley the wrong way round..?

Cheerio,

RE: Y-axis crash detected....driving me nuts

@buckeyestargazer

I would not rely on the belt tension indicator on the LCD and prefer to check the tension mechanically.

You can print yourself a simple tool for this purpose: belt-tension-meter-for-gt2-beltswbr,

Karl

...and this Belt Tension meter, I was told from Prusasupport this is not for mk3s, only for the Mini because they don't have the possibility to messure the belt tension with their software. Whereas I tend to believe you more, because you are my "GOD OF SUPPORT" with your help and hints, I managed a lot of issues.

@bucketeyestargazer Do you print ASA or ABS in an enclosure ? Because temperatures above 40Degrees can cause y crashes, at least in my and and a few other user cases.

MK3s, Ender 5

RE: Y-axis crash detected....driving me nuts

@sebbl2

The tensionmeter can be used for the MKx, Mini and some other printers with 6mm GT2 belt. You can pre-adjust the belt tension quite well with it. The fine adjustments can then be made, depending on the calibration and print results. I built my own device, which gives pretty much identical results and works reliably.

(usable for 6 and 8mm GT2 belts)

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis crash detected....driving me nuts

@karl-herbert

ok than I will use my printed one again.

MK3s, Ender 5

RE: Y-axis crash detected....driving me nuts

@sebbl2

Mini x-axis

Mini x-axis

MK3 x-axis

MK3 x-axis

In addition to correct belt tension, it is also important that the Lienar bearings move smoothly and do not jam anywhere. It is advisable to clean the rods and relubricate the bearings from time to time. If all this is correct, the recommended Prusa belt values (see LCD) should be approximately achieved.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis crash detected....driving me nuts

I finally had a chance to print the belt tension meter and the meter showed the tension was a little low, just below the "min" line. I tightened it up but it made no difference. A 1hr print resulted in two Y axis crashes.

RE: Y-axis crash detected....driving me nuts

@buckeyestargazer

Make sure the y-pulley is not spinning around the motor shaft. The stepper motor could also have a defect. If this is all in order, you could run the calibration procedure again. The last step would be to contact the Prusachat.

good luck!

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis crash detected....driving me nuts

@karl-herbert

karl,what is your opinion of high enclosure temperature is causing the y-crash. Because hours an hours printing petg and pla won’t produce this effect. ASA does. Degrees raise to 48 and after one h I have these problems as well. I just turned off crash detection, but this solution shouldn’t been made

MK3s, Ender 5

RE: Y-axis crash detected....driving me nuts

@sebbl2

The Prusa printers normally are not designed to operate in an enclosure. If you use an enclosure, I would look for max. temperatures about 35-40 degrees C. The electronics heat up too much at higher temperatures, which can lead to malfunctions of various components. With a filter/fan regulation you can control the temperatures in the enclosure relatively easy.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.