What is causing this strange artifact when printing PLA?

Hi All,

I wonder if anyone can help me before I need to buy any new parts. About a week ago my MK3S had a print failure where PLA accumulated in large quantities at the hot end, blocking the fan and damaging the thermistor and fan shroud. I bought a replacement from prusa3d, I replaced the thermistor sucessfully using this guide step by step ( https://help.prusa3d.com/en/guide/how-to-replace-thermistor-in-the-extruder-mk3s_131675 ) and finally printed a new shroud out of ABS and the printer prints again, but now I have a quality issue.

A strange print artifact appears in my PLA prints, and I am not sure what is causing it. I have attached pictures of what results I am expecting and what results I am getting i.e. a sample printed before the repair (figure 1) and a sample printed after the repair (figure 2). In figure 2 (the bad sample) the failure only occurs on one side of the cylinder. It starts as a gradient so isn't too noticable until it gets progresively closure towards the 'einsy side' of the printer, then it seems to have a sharp transistion back to normal.

Could this be bad cooling? It looks like ghosting caused by some 'tugging' on the umbilical, but the printer has no problem moving it's axis. Any ideas? Are there any tests I can perform to rule out certain causes?

Figure 1 - A good sample printed before the repair. The artifact doesn't exist and it is a perfect print.

Figure 2 - A sample printed with the same print settings after the printer repair.

Figure 3 - Both samples compared together (left is good sample, right is bad sample).

RE: Try slowing

Some this might be an artifact of print speed. Slow the print speed and it might improve.

Take a picture before you remove it from the print plate so we can see orientation.

--------------------

Chuck H

3D Printer Review Blog

Hmmm

Hi cwbullet thanks for your reply. I am using default PrusaSlicer settings for Generic PLA so print speed should not be the issue (I will do some test prints at slower speeds though to see if this helps).

In fact I believe I've determined the problem, the ubilical from the einsy to the hotend carriage is sagging and rubbing on the heatbed cable. It only does this when the X-carriage is at the leftmost side of the printer (this explains why it only happens in one place in the print). I started the print again and kept it out the way with my hand while it printed and the quality issue went away, but of course it isn't a permenant solution!

I am going to print some cable chains to constrain the umbilical, to see if that helps.

Prusa Support Lol

Hi, when you replaced your thermistor, did you ensure that the NYLON Support filament was properly installed in the umbilical between the rear of the extruder, and the einsy box.

this filament normally prevents your umbilical from sagging...

It is usually fixed in mounting holes at both ends. one on the rear of the X carriage, and one on the Einsy case

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Doh!

Thanks for your reply JoanTabb!

I am assume it is sagging because it never rubbed on the other cable which feeds the heatbed before! Checking the Nylon support filament is a good spot, I had to undo some of the cable ties to insert the new thermistor so maybe I moved it by accident? I will check tonight.

most likely issue is the Einsy end!,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Yes it was!

Hi JoanTabb,

Looking inside the einsy case and inspecting the nylon filament didn't immediately offer up any obvious points of failure. However I removed it from the einsy side and re-seated everything so at least the cables don't rub anymore...

...and as if by magic the problem is now gone! Obviously I had dislodged the Nylon filament when installing the new sensor. Thanks for your help!

GOOD NEWS!

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

New problem now!

Hi All,

I am sorry to ressurect this thread but it appears the problem never really went away. The quality of my prints has never been the same since the repair. In thought I fixed it until I started printing with some different colour filament. It turns out black PLA shows how pronouced the artifacts are (as opposed to white). I fixed the nylon filament which definately helped reduce the artifcats I was originally bothered by but some still remain.

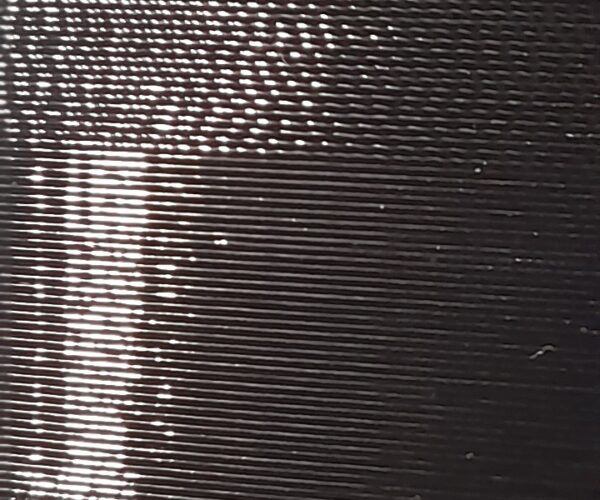

I have attached the photograph below. At first I thought it might be the cooling fan (since the original fault caused PLA to enter the fan shroud), so I replaced that with a new fan and shroud with Prusa original parts. However the problem persists! You can see that there is a 'wobble' in the layer lines, these only appear along the Y-axis.

I am not sure if this is related to the original problem but I assumed so since it never happened before the failure? There is some clicking from the X-axis bearing but that has always been there since the printer was built (perhaps I should fix that first?).

Does anyone know what causes these wobbles? Do you think it could be the bearing?

If your idler bearing is failing the grinding will affect the print, gradually getting worse until complete failure.

With the printer off slide the axis all the way, is it smooth? Try to feel the bearing with your fingertip as you move the axis, does it vibrate or judder?

Cheerio,

When My X idler collapsed, I found replacement items with dual bearings. and I now use them on all of my printers,

they are 20 t00th gt2 idlers, (either toothed, which I prefer, or smooth which is more in line with the prusa design the belt size is 6mm width and the mounting bolt hole size is 3mm

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

No damage to idlers

Hi All, Sorry it's been a few days. I checked the idlers and they are smooth and I cant see any vibration or wobbling from either the X or Y idlers. The bearing on the smooth rods are clicking but I checked with prusa support who don't think this is an issue (i sent them a video; https://vimeo.com/manage/videos/640901474). They said if there is no grinding on the smooth rods then there is probably not an issue, but I have applied some grease anyway to lubricate them.

They believe the issue could be in the hotend, and suggested that some material could be stuck in there. However I have done multiple cold pulls and I'm quite sure there's no foreign material left in the nozzle. Do you think replacing the nozzle could be the solution?