underextrusion / extruder or slicer problems?

Strange underextrusion:

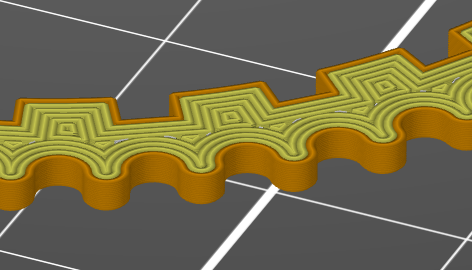

it should look like this. And I have printed 20 variants (pieces) before without problem.

after ejecting the material you can see a Multi-Filament-Tip (hairy tip)

The extruder is working fine as you can see from the transportation marks. The extruder gears are clean. (nothing inside)

then I reloaded the filament:

without underextrusion or clogging.

here are the files: Underextrusion

Thanks for help - Carsten

Best Answer by Neophyl:

I had a go at printing both your 3mf using your settings and the one I posted as a comparison. Before I go on I will say that my printer is getting close to needing a teardown and rebuild as when I built it the manual made no mention of greasing the bearings, so I didnt. As I've come to learn I really really should have and so they are getting noisy now and quality is down due to the scored rods. I don't normally see under extrusion on my printer on my regular models but I also dont usually do really small stuff

The one on the left is using my 0.2 layer height slice with the reduced walls, but the base/top layers still mean there's no real infill used. The right hand one is your 3mf at 0.1 layer height with 9 perimeters etc.

The one on the left is using my 0.2 layer height slice with the reduced walls, but the base/top layers still mean there's no real infill used. The right hand one is your 3mf at 0.1 layer height with 9 perimeters etc.

You can see some of the top plastic appears to be missing for a section of the arc with yours. Not sure why as it looks fine in the slice. The fact that its only on party of the gear and not all the way around is also mystifying.

Personally I think the 0.2 layer one came out a lot better and visually the difference in layers isn't really noticeable except under a magnifier.

The other big difference is at 0.1 it took nearly and hour (58 minutes) while at 0.2 it took 21 minutes to print.

I think this is one of those cases where experimenting with settings is of great benefit.

ps - you sure must be away from your printer a lot as those beeps in your start and end gcode are bloody loud and annoying lol. I had to hit reset after the print to shut it up early.

and after restarting the print, again and again underextrusion

and after restarting the print, again and again underextrusion

RE: underextrusion / extruder or slicer problems?

No clue how it was sliced; you may be doing something there that is the problem. ZIP and post the exported project (3MF).

RE: underextrusion / extruder or slicer problems?

@ tim, my "Famed Member" is the file I attached in my first post not enough?

RE: underextrusion / extruder or slicer problems?

Carsten, the 3mf file you attached is more than sufficient, thank you for including it :). I'm at the start of a 6hr print at the moment but will give it a go overnight after the current one has finished. I might change it to 0.2 layer though as that should be just as strong if not stronger than 0.1 and will finish a bit quicker.

Can I ask what filament that is ? I see the project is set for Prusament PLA but I've never seen a multi-string tip like that before. Initial thoughts is something clogging the nozzle. Have you done the usual cold pulls to check that its clean ?

RE: underextrusion / extruder or slicer problems?

@neophyl

hi, the filament is prusament. The one they sent with the printer ;o) have you seen the video in my first post? I think there is nothing clogged. The printer has printed 50 Meters of this spool. I will check the nozzle again ...

RE: underextrusion / extruder or slicer problems?

It appears it may be a positional issue as much as under extrusion. You might want to check your belts and drive gears. Also, what does the rest of the printed gear look like? From what I can see the issue is only on one area of the circumference?

Are you doing any post process of the gcode? Some of the elements in the image look more or less impossible - as if printer scale is changing during the last layer and/or a new part is being printed on top the existing part.

ps: famed member is the tag the forum puts on - not my choice.

pps: I'd like to see the gcode that produced that print.

RE: underextrusion / extruder or slicer problems?

You're forcing retractions/wipes on structural critical positions. I would suggest 3 perimeters, make it solid (increase the top layers) and go with 0.2 layer height. It should give you pretty structural strong part.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: underextrusion / extruder or slicer problems?

Didnt realise it was a video with it having IMG in the name, thought it was an image. Are prusa now sending out prusament with printers ? The one I got was the normal prusa filament, the non prusament stuff which has a slightly different profile (the Prusa PLA one).

RE: underextrusion / extruder or slicer problems?

Also I agree with Nikolai that the number of perimeters is not needed. Personally I would print it like in the attached project -

RE: underextrusion / extruder or slicer problems?

I will check everything. The File from neophyl is looking better (Nikolai's suggestion) than mine :o) The cold pull was crystal clear, as suggested.

RE: underextrusion / extruder or slicer problems?

I had a go at printing both your 3mf using your settings and the one I posted as a comparison. Before I go on I will say that my printer is getting close to needing a teardown and rebuild as when I built it the manual made no mention of greasing the bearings, so I didnt. As I've come to learn I really really should have and so they are getting noisy now and quality is down due to the scored rods. I don't normally see under extrusion on my printer on my regular models but I also dont usually do really small stuff

The one on the left is using my 0.2 layer height slice with the reduced walls, but the base/top layers still mean there's no real infill used. The right hand one is your 3mf at 0.1 layer height with 9 perimeters etc.

The one on the left is using my 0.2 layer height slice with the reduced walls, but the base/top layers still mean there's no real infill used. The right hand one is your 3mf at 0.1 layer height with 9 perimeters etc.

You can see some of the top plastic appears to be missing for a section of the arc with yours. Not sure why as it looks fine in the slice. The fact that its only on party of the gear and not all the way around is also mystifying.

Personally I think the 0.2 layer one came out a lot better and visually the difference in layers isn't really noticeable except under a magnifier.

The other big difference is at 0.1 it took nearly and hour (58 minutes) while at 0.2 it took 21 minutes to print.

I think this is one of those cases where experimenting with settings is of great benefit.

ps - you sure must be away from your printer a lot as those beeps in your start and end gcode are bloody loud and annoying lol. I had to hit reset after the print to shut it up early.

RE: underextrusion / extruder or slicer problems?

THX,

with the new parameters, the prints are looking great again. (Interesting, that the first ones had been better).

some answeres:

this is the prusament from prusa ... I have seen the barcode and thougt, ah prusament. But I think it is filament, sent by prusa (with the new printer) manufactured by "IDONOTKNOW". It is very good looking especially the printed frog.

The sound:

yes, the printer is far far away in my prepping bunker ;0)

and the beeps in the beginning will remember me, that at the end will be an awakening BEEP concert. If I do not want to wake up, I can uncomment the beeps.

Carsten

RE: underextrusion / extruder or slicer problems?

The variation is mainly due to perimeter count. Using 9, the slicer is trying to honor the 0.45 mm widths for all tracks; with only two or three, the slicer has more flexibility to handle infill properly.

That still doesn't explain why there is an extra layer of material on the OP images.