Re: The current MK3S extruder body is 0.4 mm loose(r)

I also prefer Gyroid nowadays because of even distribution of forces. But it's not "the best" infill for any purposes. Sometimes it's better to take others that why we still have all other available 😉

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: The current MK3S extruder body is 0.4 mm loose(r)

As you can see grid is perfect if the part is loaded exclusively in the printing direction (Z axis). For all-round (XYZ axis) or rotary/torque (ABC axis) loading cubic or gyroid is much better suited.

Thanks, very nice video! I agree with your summary.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone create R4 parts for the original sensor?

The Latest Firmware can be found here https://github.com/prusa3d/Prusa-Firmware/releases

Open Firmware Issues https://github.com/prusa3d/Prusa-Firmware/issues

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone create R4 parts for the original sensor?

already done by someone

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone create R4 parts for the original sensor? The original sensor is better than the new On Off switch. Changing the sensor is a step backwards it just needs to be applied in a different way using a bearing that is pushed out when filament is inserted

The Latest Firmware can be found here https://github.com/prusa3d/Prusa-Firmware/releases

Open Firmware Issues https://github.com/prusa3d/Prusa-Firmware/issues

Re: The current MK3S extruder body is 0.4 mm loose(r)

The original sensor is better than the new On Off switch.

Humm. Having used the IR sensor for a while, I would disagree with you on this.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: The current MK3S extruder body is 0.4 mm loose(r)

I'm always wandering how fast people make a decision what is really good or bad. R4 extruder and the new sensor is just being released in the wild. It's hard to tell how it will perform for the majority of people.

Anyway thanks to the Prusa community we will have all variations of extruder and filament versions. So there is/will be something for everybody.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone create R4 parts for the original sensor? The original sensor is better than the new On Off switch. Changing the sensor is a step backwards it just needs to be applied in a different way using a bearing that is pushed out when filament is inserted

Maybe you should read replies to your posts instead of just spamming this everywhere?

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone perhaps do a comparison between the tweaked version and the stock version to see if the tolerance change has a noticeable practicable impact?

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone perhaps do a comparison between the tweaked version and the stock version to see if the tolerance change has a noticeable practicable impact?

Second post in this thread (and perhaps the entire point of it?)

Re: The current MK3S extruder body is 0.4 mm loose(r)

Can someone perhaps do a comparison between the tweaked version and the stock version to see if the tolerance change has a noticeable practicable impact?

Second post in this thread (and perhaps the entire point of it?)

Indeed, but aside from mentioning some potential wiggle, nobody seems to have done tests or anything to see if it has a negative impact on print quality/reliability/etc. Not trying to be difficult, but there are already a lot of mods floating around with uncertain if any benefit aside. Now I'm sure that's half the fun for some, and that's fair, but I wonder if these things should perhaps be approached a bit more scientifically. (That said, it's perfectly possible that Prusa actually messed up, it has happened before).

Re: The current MK3S extruder body is 0.4 mm loose(r)

Indeed, but aside from mentioning some potential wiggle, nobody seems to have done tests or anything to see if it has a negative impact on print quality/reliability/etc. Not trying to be difficult, but there are already a lot of mods floating around with uncertain if any benefit aside. Now I'm sure that's half the fun for some, and that's fair, but I wonder if these things should perhaps be approached a bit more scientifically. (That said, it's perfectly possible that Prusa actually messed up, it has happened before).

Any wiggle of the nozzle tip will result in inaccuracy. If you want to do tests, just loosen some bolts on your extruder and print something. This is also apply to Y-axes and Z-axes. You shouldn't have any wiggle there as-well.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: The current MK3S extruder body is 0.4 mm loose(r)

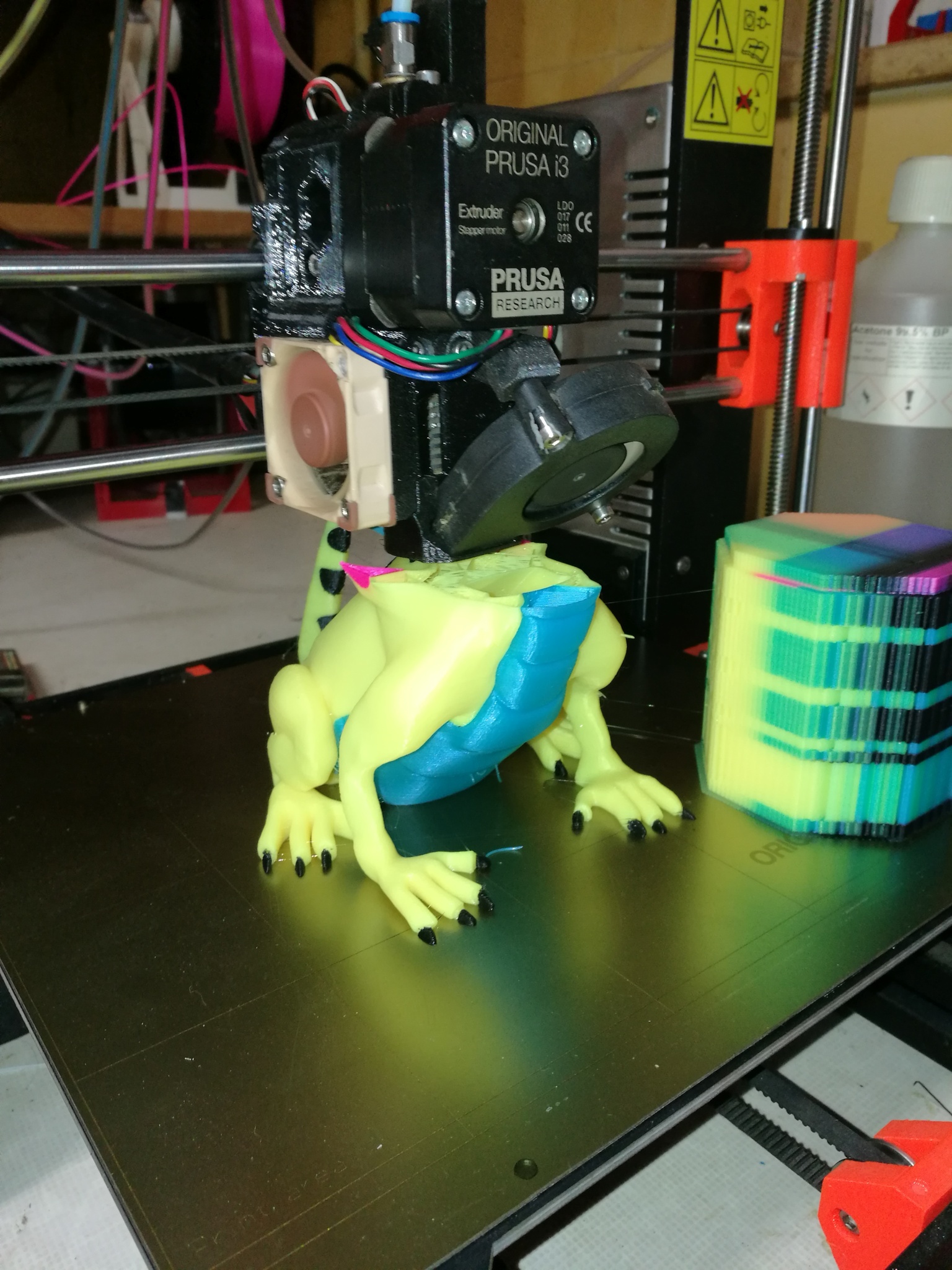

Any wiggle of the nozzle tip will result in inaccuracy.

Not seeing any "inaccuracies" here:

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: The current MK3S extruder body is 0.4 mm loose(r)

Indeed, but aside from mentioning some potential wiggle, nobody seems to have done tests or anything to see if it has a negative impact on print quality/reliability/etc. Not trying to be difficult, but there are already a lot of mods floating around with uncertain if any benefit aside. Now I'm sure that's half the fun for some, and that's fair, but I wonder if these things should perhaps be approached a bit more scientifically. (That said, it's perfectly possible that Prusa actually messed up, it has happened before).

Any wiggle of the nozzle tip will result in inaccuracy. If you want to do tests, just loosen some bolts on your extruder and print something. This is also apply to Y-axes and Z-axes. You shouldn't have any wiggle there as-well.

I think you're missing the point completely. Loosening bolts on the extruder is not the same as adding slightly more tolerance to the extruder.

It's possible, and maybe even likely, that the change to the exruder housing will reduce print quality. But to claim that it actually has that effect when nobody has apparently tested it is wrong. It's also possible that Prusa discovered the old piece didn't have enough tolerance and they corrected the mistake.

TL;DR: Pics or it didn't happen.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Guys, if it doesn't affect you and your printer produce great results then it's fine. And I will not even try to make any point here. This is not like somebody is making up something. Check the original post how everything began.

One guy printed new extruder housing, assembled it and realized e3dv6 extruder is not sitting tight fit inside. Maybe it was his print setting, maybe his printer maybe assemble but it was a good catch that the design had 0.4 more space where it shouldn't be which gives more room for wiggle. If the modified design helps this guy then it's a good thing. I'm pretty sure there are a lot more people out there appreciating this option.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: The current MK3S extruder body is 0.4 mm loose(r)

Since the extruder is held by the collar around the upper neck of the heat sink, and NOT the heatsink fins, that is where I'd begin looking for fitment issues. Besides, it is clear in the drawings the Mk3 extruder housing had 0.2 mm play at the fins, thus had the exact same wobble possibility as the Mk3S extruder housing, though a bit smaller.

We don't know if the OP had a part that is undersized due to printing technique or even material shrinkage that made the collar too large for the heat sink. It might be premature to blame Prusa's design.

Anyway - I ordered parts from Prusa - we'll see if they are a good fit compared to parts I made using cheap Amazon PETG; I printed parts with my own slice, and with Prusa gcode. I also printed the "corrected" parts in this thread.

Prusa e-mailed me a note saying my parts have been shipped ... results should be interesting.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Many extruder designs (such as on the HyperCube) do not constrain the E3D v6 heat sink at all. The normal E3D cooling fan mount actually clips on to the sink with no connection to the extruder body at all - the only mounting point is the top grooves. According to E3D this is the only mounting required for the v6. These printers do not suffer with print issues caused by wiggling nozzles.

Always happy to be proven wrong but I would be very surprised if this extra tolerance in the heat sink to extruder plastic interface makes any difference at all to the rigidity of the hot end.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Just to let you know that Prusa are going to take look at this and see what's up...

Re: The current MK3S extruder body is 0.4 mm loose(r)

Holding a heatbreak just by its neck will work for a while. When you have big prints with grid infill, the head often does bump into the infill when traveling around. It produces strong side forces that weaken the grip, so having a tighter extruder body that holds the heatbreak even near its bottom helps a lot in minimizing these effects. So these are not the effects that one is likely to see immediately in the first prints, but yeah, soon enough the problems are likely to occur.

Re: The current MK3S extruder body is 0.4 mm loose(r)

I am curious why Prusa recommends Grid over Gyroid.

I've heard that gyroid is slower and doesen't provide any measureable benefits.

Or do you know any sources that measure the advantage of gyroid over grid?

CNC Kitchen did crush tests. I did torque tests.

https://laplacean.wordpress.com/2018/05/17/gyroid-infill-tests/