The current MK3S extruder body is 0.4 mm loose(r)

Hi all! In case you haven't already seen this post on FB https://www.facebook.com/groups/Prusai3users/permalink/1126638230853990/ , a user has noticed that the new MK3S extruder body model is looser than the old one by 0.4mm which causes the extruder to wiggle.

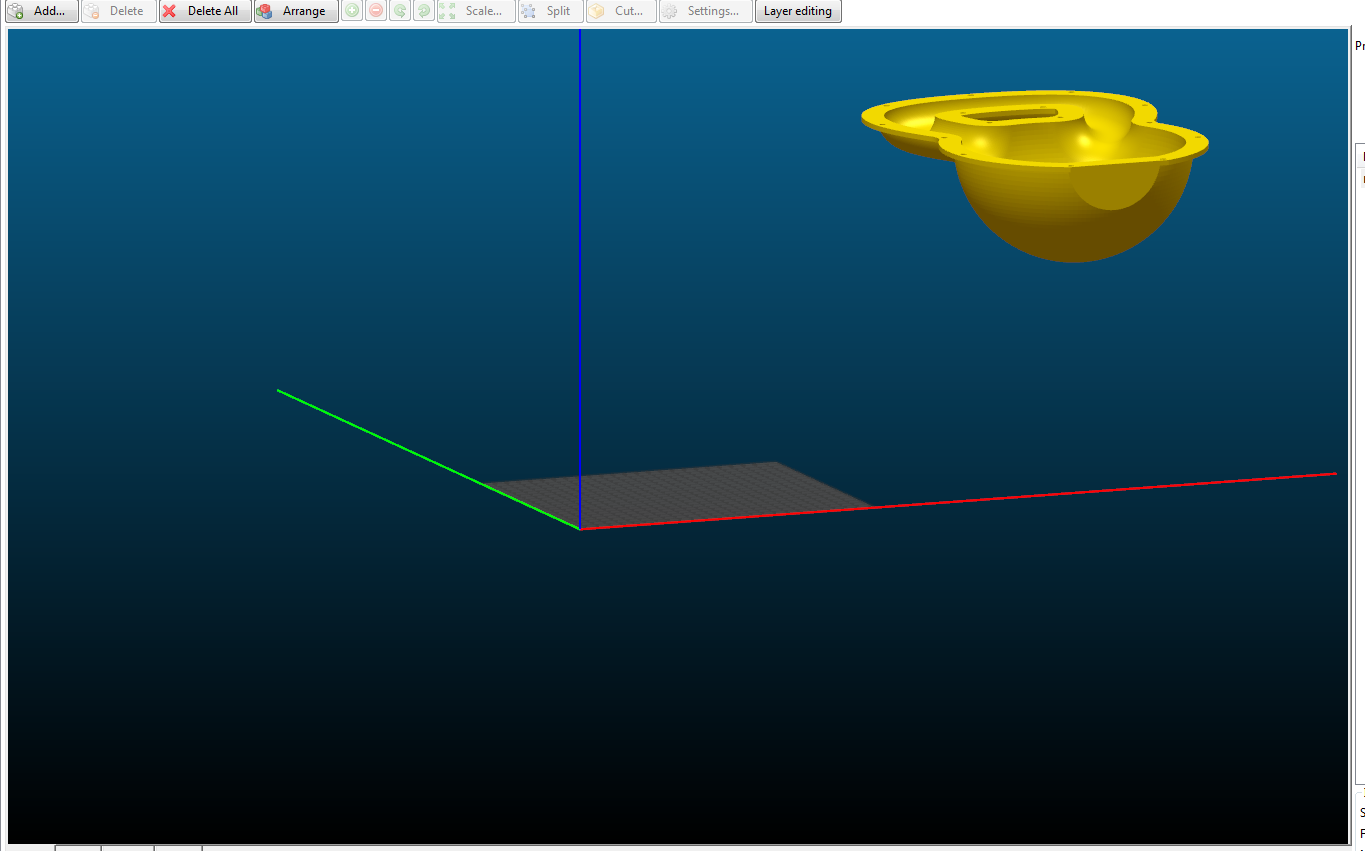

To test his statements, I did a quick test in TinkerCAD, where I imported the extruder body and subtracted it from a thin square block to measure the opening. I did that for the new MK3S model dated 12.2.2019 and for the old MK3 model dated 14.1.2019, and on the snapshots below you can see that the new model indeed leaves 0,4 mm more space around the heatbreak near the heatblock.

Why was the model widened in the first place, and will it be fixed?

Thanks and cheers!

P.S. The user who reported the issue on the FB tested that with a spare heatbreak clone before building it into his original MK3, so some other users noticed that a difference between the clone and the original part may be causing the part to wiggle, but the experiment proves that the new extruder model is wider by 0.4 mm, making the clone argument irrelevant in this case.

P.P.S. I haven't yet tested the model, because it is still printing, but the fact that the new one is 0.4mm looser than the old one definitely makes me feel uncomfortable, and I won't start disassembling my printer until I get an explanation. I can't remember the old one being too tight when I assembled it back then, so if it was any looser, I am sure the things would have started wiggling around...

P.P.P.S. I've seen comments like "I've tried and mine does not wiggle", but if you have a heatbreak that until now was residing in a smaller extruder body, and now you put it in another one that leaves more space, but it still seems to be snug, how do you know it won't start wiggling once the heat kicks in melting the ridges that were keeping it in place, and the whole thing starts moving around?

Re: The current MK3S extruder body is 0.4 mm loose(r)

Yes. The hotend wiggles around in there. It is too big.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Is the rest of the extruder housing same size and only the opening is wider?

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: The current MK3S extruder body is 0.4 mm loose(r)

Is the rest of the extruder housing same size and only the opening is wider?

It is pretty much in +-0,05mm range, but it is obvious that a different template was used for the extruder. The opening should have been left the same as in the original MK3 extruder, since it was proven to be adequate.

I am working on my own MK3S R4' model based on the current MK3S R4, but with the opening taken from the old MK3. I would prefer an official model, though, or at least to hear an explanation if that was made with some purpose, or was it just a glitch.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Hello all,

It is only the opening for the heat sink at the bottom of the extruder body that is larger. The clearance at the neck is the same allowing for the fact that the R3 are designed to allow the heat sink to be tilted for removal. It looks like Prusa designed the heatsink mounts based on E3D's documentation which has the heatsink only fixed at the neck and not the base.

Really there is no reason to increase the hole size at the bottom and in fact it should be kept at a 0.1mm clearance all round rather than the 0.25mm in the new design. As it stands there is a chance that air from the Noctua fan hold leak through this gap.

Regards,

Martin

Martin Wolfe

Re: The current MK3S extruder body is 0.4 mm loose(r)

Really there is no reason to increase the hole size at the bottom and in fact it should be kept at a 0.1mm clearance all round rather than the 0.25mm in the new design. As it stands there is a chance that air from the Noctua fan hold leak through this gap.

This is a concern for the part cooling ducts. It was found that on the R3 extruder that the noctua air blowing down was blowing hot air onto the part cooling duct (for some reason, preferentially on the wire side of the heat block causing that side of the cooling duct to start drooping down during high filament temperature prints. (The air blowing down was pre-heated by the heatsink and then heated more from the top of the heat block.

I wonder if strategic application of kapton tape would ameliorate that issue... (And/or reprinting the part cooling duct in PLA (or HTPLA) then annealing it.)

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

Re: The current MK3S extruder body is 0.4 mm loose(r)

As I will have to lower the PINDA mount for my Volcano mod and have already lowered the fan side mount I will be reducing this gap on my Volcano version of the parts.

Regards,

Martin

Martin Wolfe

Re: The current MK3S extruder body is 0.4 mm loose(r)

Does anybody know how much closer the hotend is to the X-Axis in the MK3S? Prusa claims to have improved this, but they don't show any numbers.

Re: The current MK3S extruder body is 0.4 mm loose(r)

Here's my modded version of the R4 extruder holder with the bottom opening set to 22.4 mm, as it was on the good old R3: https://www.thingiverse.com/thing:3428292 .

Re: The current MK3S extruder body is 0.4 mm loose(r)

Does anybody know how much closer the hotend is to the X-Axis in the MK3S? Prusa claims to have improved this, but they don't show any numbers.

The extruder mounting face of the x-carriage is exactly the same distance from the centre line of the x-axis steel rods on the R4 parts as it is on the R3 parts so as a result the only change in distance is the 0.05mm closer in the R4 extruder to the R3. Considering that this is pretty much printing tolerances it is no change. Leaving only the distance change of the extruder motor being 2.5mm closer to the x-axis.

Regards,

Martin

Martin Wolfe

Re: The current MK3S extruder body is 0.4 mm loose(r)

Has anybody correlated this to actual print defects or is this a mental exercise at this point? Have there been any actual changes to print quality by "correcting" this issue?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: The current MK3S extruder body is 0.4 mm loose(r)

Has anybody correlated this to actual print defects or is this a mental exercise at this point? Have there been any actual changes to print quality by "correcting" this issue?

This looks to me like an obvious candidate for several issues that are likely to arise. Wobbling being one, hot air leakage onto the model being another. I am not eager to disassemble the printer twice if not necessary, so I was just asking whether this opening was made bigger for a reason, or "just because". I know that Prusa Research has all rights to keep undisclosed whatever they decide appropriate, and I am not asking them to randomly justify their technical decisions - I am just pointing to something that seems like an obvious candidate for some specific issues.

So, until someone explains the reason behind that change, I'd rather use my own mod, since this is an open-source project. No offense or disrespect to anyone. 🙂

Re: The current MK3S extruder body is 0.4 mm loose(r)

So, until someone explains the reason behind that change, I'd rather use my own mod, since this is an open-source project. No offense or disrespect to anyone. 🙂

I like your attitude! You could use it as a signature 🙂

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: The current MK3S extruder body is 0.4 mm loose(r)

I've reported the issue over on GitHub and linked to this Topic on the Forum...

Re: The current MK3S extruder body is 0.4 mm loose(r)

I've reported the issue over on GitHub and linked to this Topic on the Forum...

Can you provide a link to the github topic? Any comments from the prusa developers so far?

Re: The current MK3S extruder body is 0.4 mm loose(r)

I've reported the issue over on GitHub and linked to this Topic on the Forum...

Can you provide a link to the github topic? Any comments from the prusa developers so far?

It's here: https://github.com/prusa3d/Original-Prusa-i3/issues/119 But no comments yet...

Re: The current MK3S extruder body is 0.4 mm loose(r)

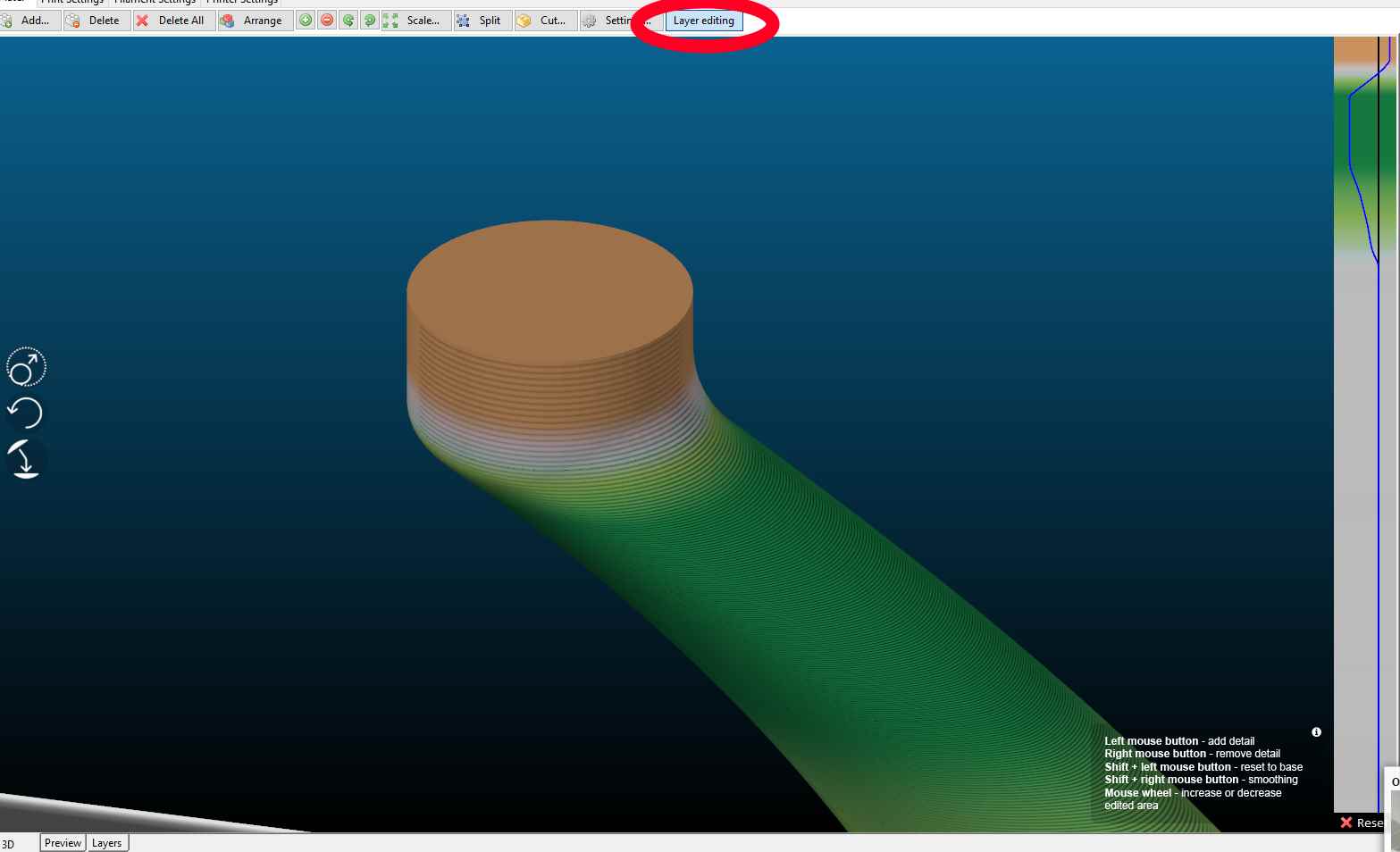

Suggested print settings for the new R4x? Or just use PETG and move on?

Re: The current MK3S extruder body is 0.4 mm loose(r)

Suggested print settings for the new R4x? Or just use PETG and move on?

The settings are specified in the thing description https://www.thingiverse.com/thing:3428292 .

BTW, rather than using Grid infill I am always using Gyroid. I am curious why Prusa recommends Grid over Gyroid.

Re: The current MK3S extruder body is 0.4 mm loose(r)

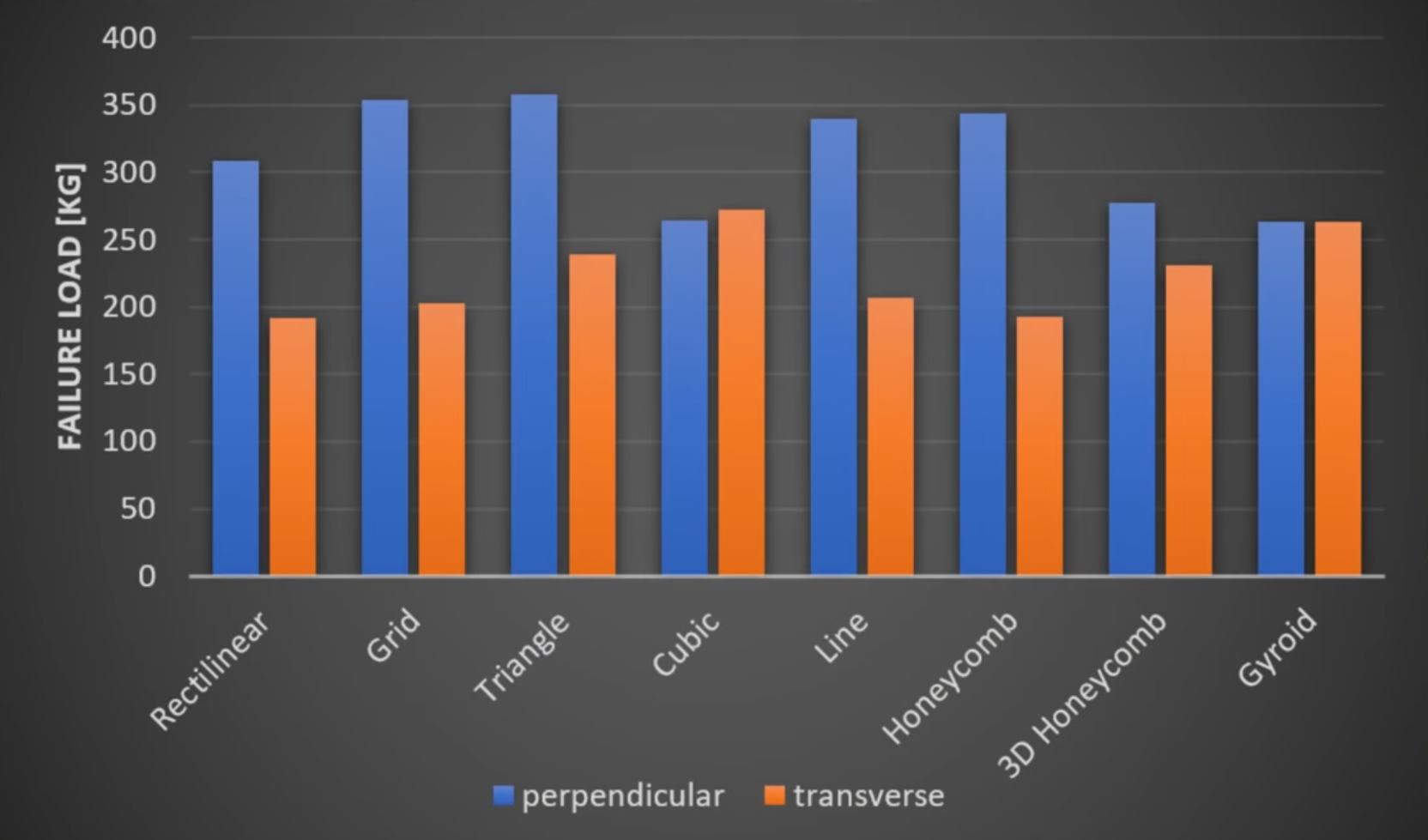

I am curious why Prusa recommends Grid over Gyroid.

I've heard that gyroid is slower and doesen't provide any measureable benefits.

Or do you know any sources that measure the advantage of gyroid over grid?

Re: The current MK3S extruder body is 0.4 mm loose(r)

I am curious why Prusa recommends Grid over Gyroid.

I've heard that gyroid is slower and doesen't provide any measureable benefits.

Or do you know any sources that measure the advantage of gyroid over grid?

Stefan from CNC Kitchen did some tests:

As you can see grid is perfect if the part is loaded exclusively in the printing direction (Z axis). For all-round (XYZ axis) or rotary/torque (ABC axis) loading cubic or gyroid is much better suited.

Unfortunately, Stefan didn't do any torque tests. I can only assume that gyroid would still stand out cubic here due to its geometry.

For these reasons (and because it looks nice 😀 ) I use gyroid as my general purpose infill and choose others just for special cases.