Strong oozing and stringing, already decreased temperature

Hi everyone!

I am quite new to 3D printing. The i3 MK3S is my first printer and the kit arrived almost 2 months ago.

Since the beginning I had massive problems with stringing and filament oozing out of the nozzle. I printed PLA and PETG so far, both ordered together with the printer.

Trying to fix it, increased retraction to 2mm and lowered the hotend temperature, on the last print (PETG) to 220°C. The stringing is a bit better (not gone completely though), but the oozing is still pretty bad.

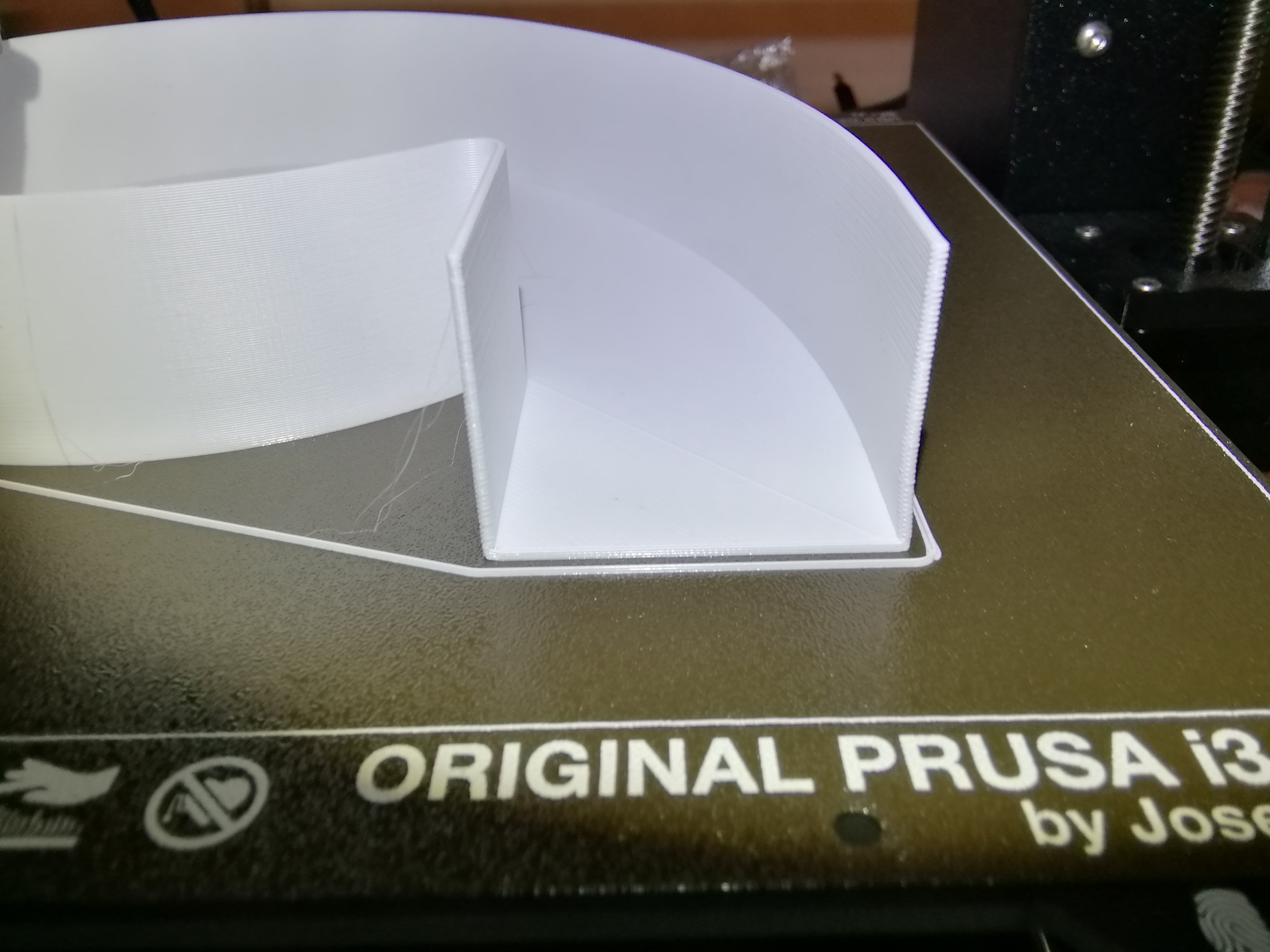

My last print (PETG, 3.8m of filament, 0.15mm speed, 1h30 print time, 220°C) even during the wiping after bed-leveling and before printing the skirt, a blob of PETG came of next to the normal wipe track. I cleaned the nozzle just before printing and paused once during the print to clean. Later I did not watch so closely and 2 more blobs got stuck on the printed object.

After the print was finished, a big blob of PETG was sticking to the nozzle. I attached a picture:

... after printing for 1h30 (but pausing for cleaning, cleaned also before printing)

... after printing for 1h30 (but pausing for cleaning, cleaned also before printing)

Can someone give me advice what else to try? Should I lower the temperature even further? This is already 15°C below default. Maybe I did something wrong during assembly? I thought about removing the nozzle and measuring the temperature inside the hotend with a better thermometer. Is it worth a try?

Best regards

Christian

RE: Strong oozing and stringing, already decreased temperature

Check your first layer, if this is to low, then filament will stick to nozzle, the nozzle will detach the filament and push it on the nozzle.

Clean nozzle before you print. Clean bed with dishsoap, and then print, if filament does not stick to the bed, it will stick to the nozzle.

Do a extruder calibration, search how to, if you extrude 100mm does the extruder extrude 100mm.

Do a calibration print , do a temp tower to see what temperature is the best for this filament.

Check if filament is not leaking higher in the extruder, on the picture i would say it is not.

RE: Strong oozing and stringing, already decreased temperature

If you're printing with sticky filaments like PETG, consider using a coated nozzle and silicone sock to keep filament from sticking to the hot printer parts instead of the print. I use E3D and P3-D coated nozzles and quite like them. Any of the V6 silicone socks with the larger opening (not the pinhole "pro" series) should work well.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Strong oozing and stringing, already decreased temperature

Oh no, I think a long reply that I wrote got lost....

Anyway....

Thanks a lot @peter-m26 and @bobstro!

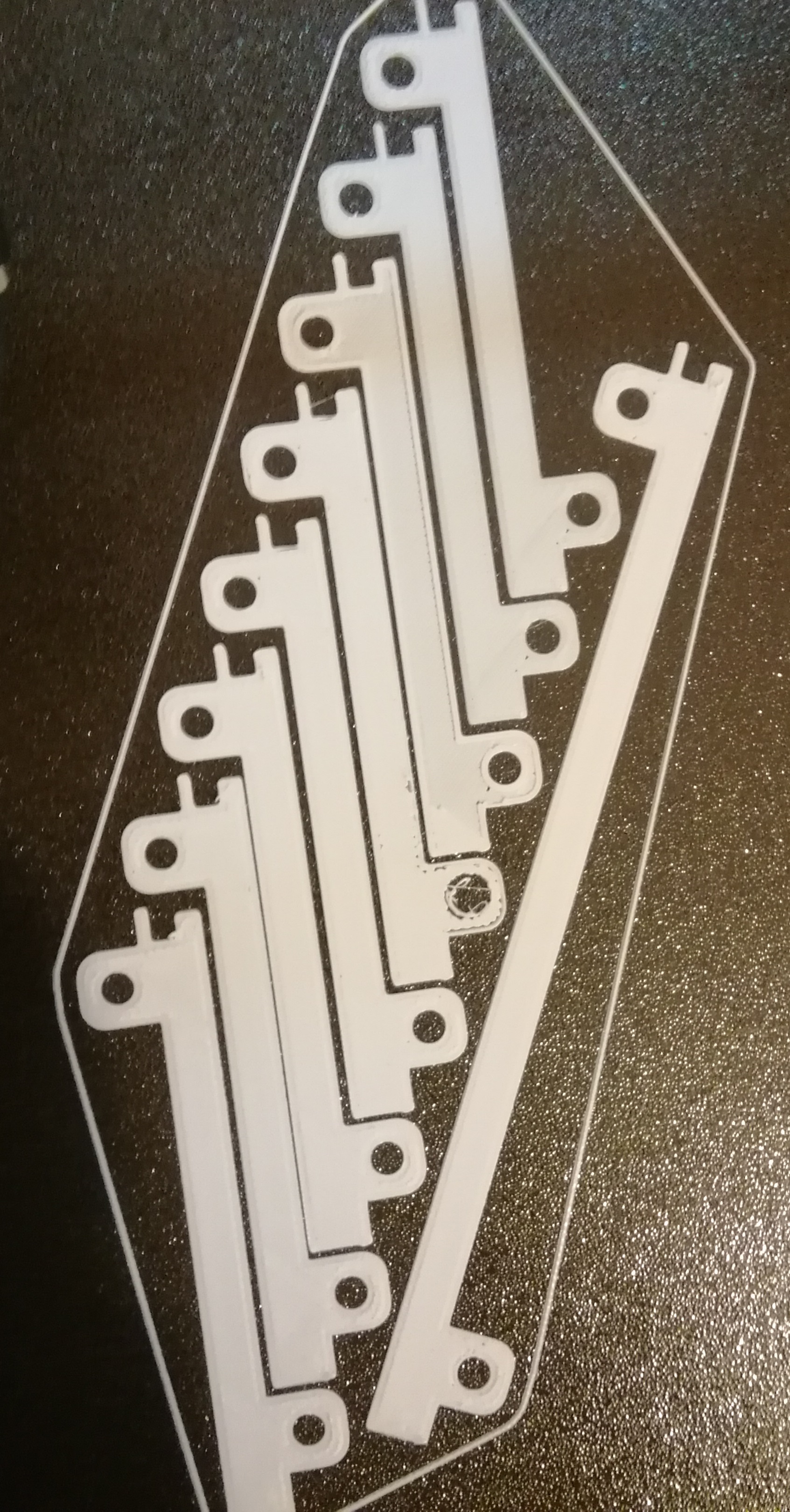

Now the details: The first layer height seemed to be really wrong.

See here:

After adjusting:

the ones on the bottom are too low. The 5th one is clearly too heigh, 7 and 8 seem to be fine.

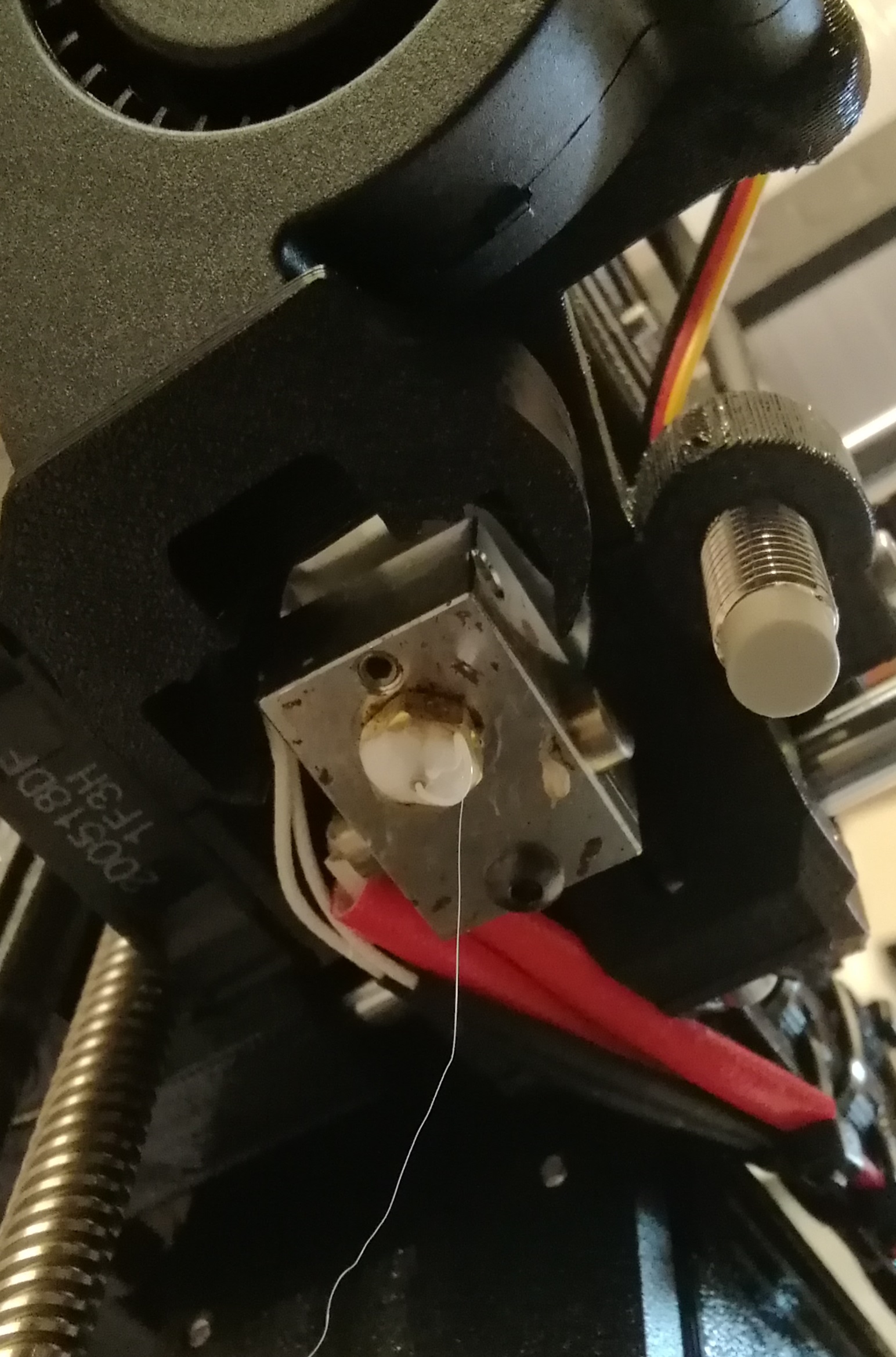

Anyway, the nozzle looked like this after the print:

Yes, I cleaned it before printing. Maybe it turned out so bad only because the first layers were already ruined.

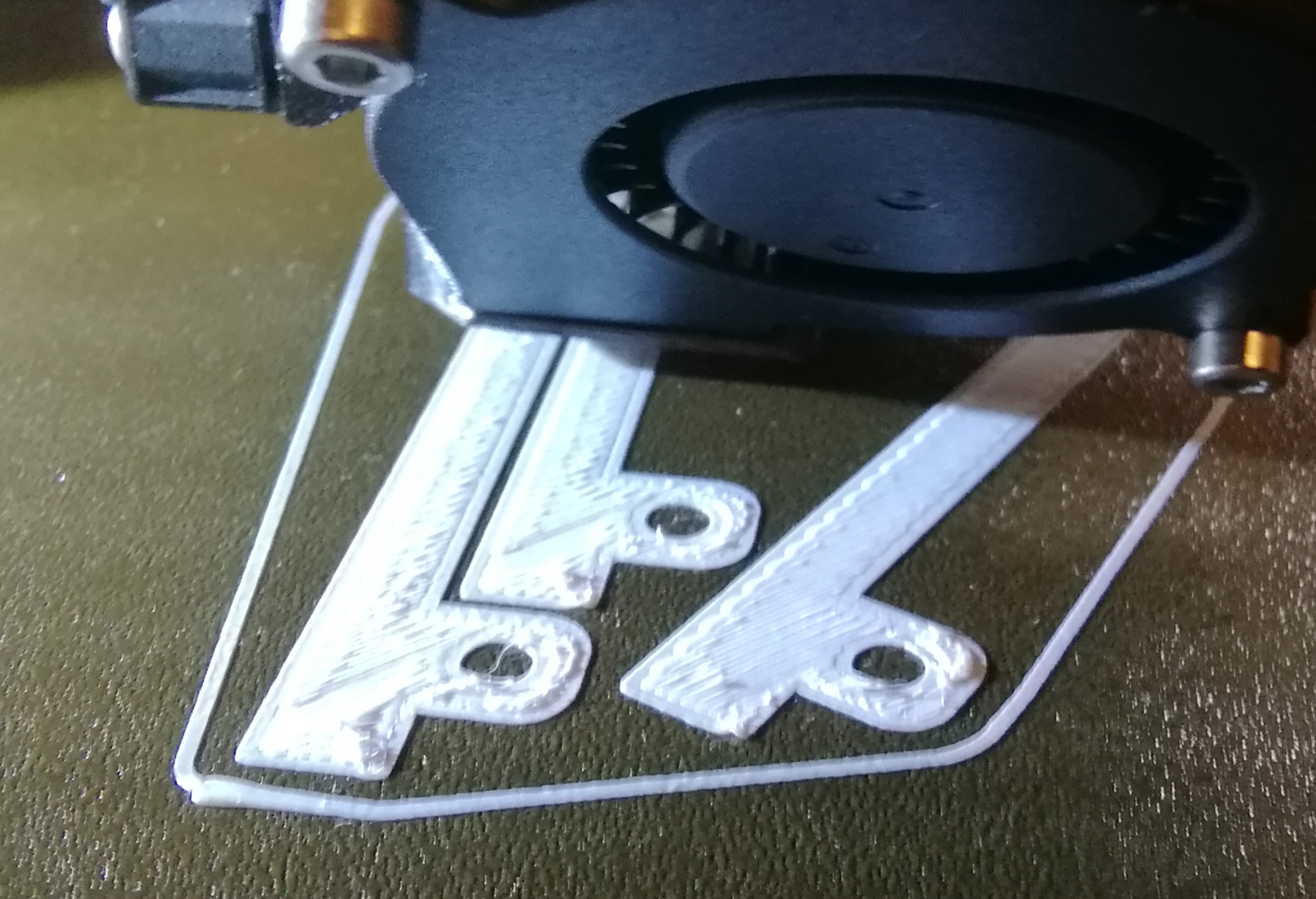

A part that is currently printing looks fine: Maybe except for the diagonal line on the bottom.

Maybe except for the diagonal line on the bottom.

I did already a temperature tower before, 230 and 240 looked fine for PETG:

Still a bit stringing.

Also I disassembled the hotend, and put different temperature sensors inside. Results were:

Printer Reading / Thermometer 1 / Thermometer 2

100 / 100,4 / 102,7

150 / 149 / 151,2

200 / 199 / 198

(boiling water) / 100,3 / 101,2

So I really think a wrong temperature is not the problem.

I printed a calibration cube, I get 0,45mm walls (my caliper can measure +-0,01mm), not sure if it is still worth to borrow a more precise tool or to calibrate the extrusion multiplier...

@bobstro: Thanks a lot for the hint with the nozzle. I'm thinking about what to buy now. Your website was also really helpful! (Btw I'm also a big fan of rubber duck debugging).

I'm undecided between the coated copper nozzle and the apollo nozzle. As copper is so soft, I would expect fast wearing. That aluminum alloy still conducts the heat better than brass and is also harder. While I am still printing no highly abrasive filaments, Nozzle X seems to have no real advantage.

Does the Apollo nozzle actually have a special coating? I can't find an explicit statement on the p3d site...

RE: Strong oozing and stringing, already decreased temperature

[...] @bobstro: Thanks a lot for the hint with the nozzle. I'm thinking about what to buy now. Your website was also really helpful! (Btw I'm also a big fan of rubber duck debugging).

Glad it's useful! Writing steps down really helps crystalize the process in my mind.

I'm undecided between the coated copper nozzle and the apollo nozzle. As copper is so soft, I would expect fast wearing. That aluminum alloy still conducts the heat better than brass and is also harder. While I am still printing no highly abrasive filaments, Nozzle X seems to have no real advantage.

P3-D uses their Duraplat plating tech. Somewhere on their web site is a bit more detail, but their nozzle and heatbreak pages describe it as:

... our electroless nickel based Duraplat3-d™ technology which is used in plastic injection and aerospace RTM carbon fiber molds for its release properties and wear resistance.

It's supposed to provide a hardened plate not as hard as hardened steel, but sufficient to make it more durable than brass. E3D's Nozzle-X is nice, but is ultimately hardened steel with the corresponding thermal characteristics. That said, I finally got a chance to do throughput testing and haven't seen huge differences in performance.

Does the Apollo nozzle actually have a special coating? I can't find an explicit statement on the p3d site...

Duraplat is described as "improving lubricity". Somewhere on their site are some pages with a bit more description. I've had good luck using their Apollo series with a silicone sock when printing PETG and other sticky filaments that like to cling to the hotend bits.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Strong oozing and stringing, already decreased temperature

@bobstro

Just out of curiousity, why not the Pro sock? That is all I have used since I started with the Prusa and it's been great so far. The nozzle pokes through through the tiny hole perfectly and it's saved my tail more than once.

RE: Strong oozing and stringing, already decreased temperature

Just out of curiousity, why not the Pro sock? That is all I have used since I started with the Prusa and it's been great so far. The nozzle pokes through through the tiny hole perfectly and it's saved my tail more than once.

Mostly because of a close call with an early test run. The sock shifted and filament was entombing my heater block. That said, I've since started wiring up my non-Pro socks and haven't noticed any shifts since.

I'd expect the Pro to make the most difference on things like spiky tops of miniatures where the heat of the block nearby is an issue. I just so happened to mount a pointy V6 nozzle today for this very reason. I may have one leftover Pro version to test again.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…