Stringing After Switching to DiamondBack Nozzle

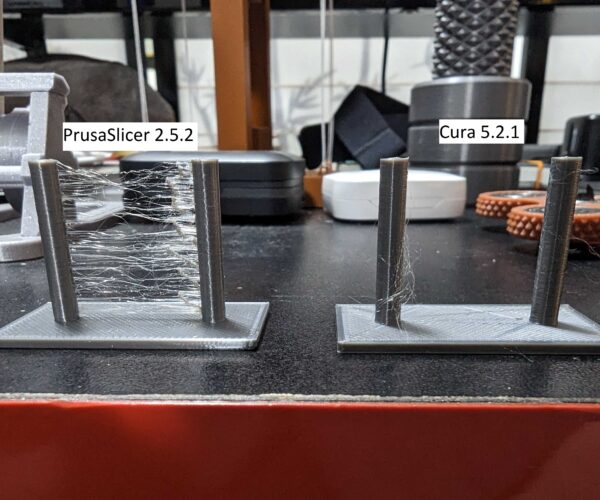

Pretty much what is says in the title. I recently changed from a 0.4mm brass nozzle that came stock to an 0.4mm DiamondBack nozzle (has a diamond for the tip). I redid both the thermal model and PID tuning after the swap just in case. Below is a picture of a basic stringing test sliced in PrusaSlicer and in Cura. Both have more stringing than I've seen with this specific roll of filament but the PrusaSlicer version is a lot worse.

Both slicers are running the MK3S+ default profiles with the only adjustment being decreasing the temp in both as per the recommendations from DiamondBack due to higher thermal conductivity. As far as I can tell the profiles are pretty much identical except for speeds. Not sure why Cura is doing a much better job except for the differences in speed. Cura is going slightly faster on the perimeters but slower on the infill and travel.

I also printed the quantitative extrusion multiplier test and the linear advance test. The extrusion was exactly right and the linear advance test looked pretty much the same except from some stringing towards the bottom when going from line to line. I've tried upping retraction distance and speed but so far it hasn't seemed to be helping the PrusaSlicer sliced files at all. But I have been trying to be conservative in my changes.

Before I go crazy is there anything I'm missing and if not are there values for retraction distance and speed that I should definitely stay under?

RE: Stringing After Switching to DiamondBack Nozzle

Temp tower for each nozzle would be interesting.

RE: Stringing After Switching to DiamondBack Nozzle

every time you change a component, you have to redo the temp and retraction tower. don't trust any recommended settings from manufacturers

RE: Stringing After Switching to DiamondBack Nozzle

Curious, did you ever figure out a "fix" for the increased stringing after going to the dimondback nozzle?