Stepper Motor softening PLA

I have been printing with Prusament PLA for a while. Recently my stepper motor has been getting hotter, which also coincided with increased jamming of the filament. I sustpected a nozzle clog but upon closer inspection saw it as the flilament expanding right before entering the PTFE tube that guides right into the hot end after the hobbed gear.

Careful disassembly led to this:

What I suspect is happening is the stepper motor is heating up, that heat is traveling down the shaft and softening the filament causing it to buckle/clog prior to entering that tube.

I have seen some suggestions on the forum of adding a heat sink or a fan to the extruder motor to address this issue. Is there another way to address this such as adjusting the stepper driver voltage to stop the motor heating up as much. It used to not do this.

Thoughts?

Re: Stepper Motor softening PLA

There was some chatter 3.5 firmware changed the driver code. But I may have been misunderstanding the conversation. You could try down-reving to 3.4.x and see if that affects things for you.

I've watched my extruder temps, and they rarely get above 50c. I think I've seen 55c once. My print room is a constant conditioned 23C; but I added a 40x40x10 heatsink to my X, Y and Extruder motors as a precaution. The heatsink dropped the extruder down to 45c typical, not much help, really. But you could add a pack of four ($10 Amazon) - back and three sides are easy - and probably get a 10 or 15c reduction.

Re: Stepper Motor softening PLA

I don't see a collet lock on the top of your heatsink... without it the PTFE can be moved up a tiny amour with each retraction creating space between the bottom cone shape of the PTFE and the top of the Heartbreak. when you reassemble use a lock being sure the PTFE is down tight to the heartbreak top,

Re: Stepper Motor softening PLA

Also, the teflon doesn't go all the way through the thermal break. It stops near the top, and it's raw metal through the thermal break and nozzle. So you can't directly compare the length of the teflon to the filament to gauge where it is getting soft.

In that picture, the filament length implies melting/squishing inside the thermal break, well away from the motor shaft.

Re: Stepper Motor softening PLA

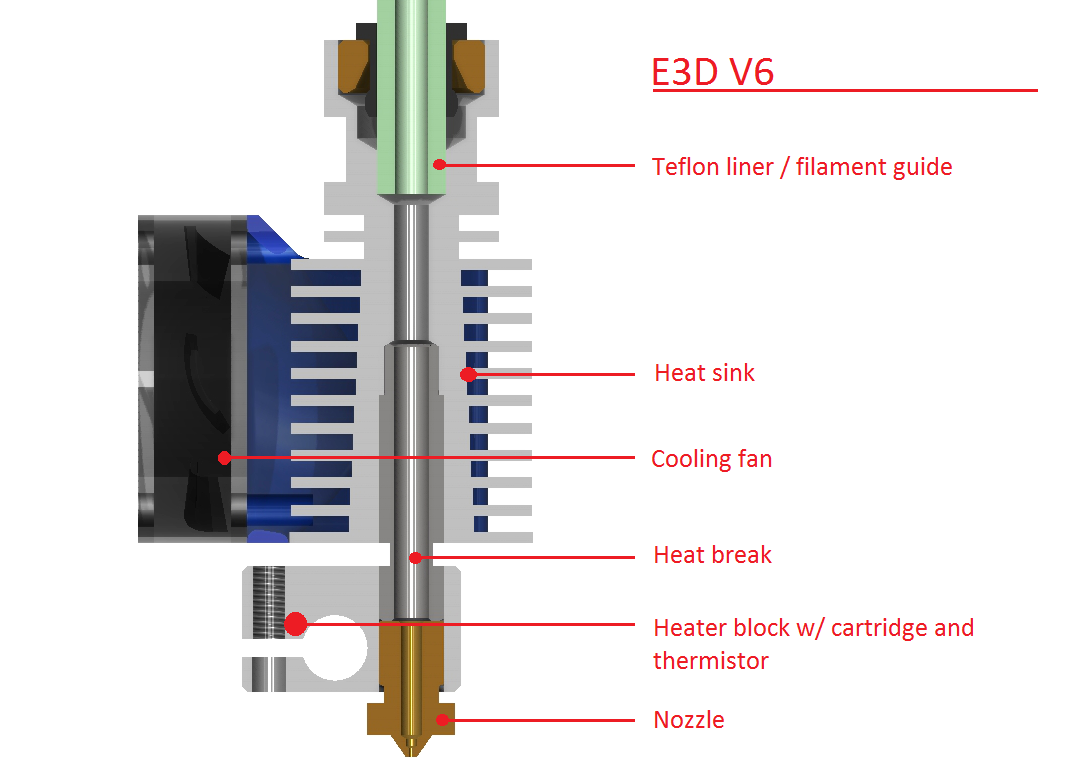

Our 1.75 mm E3D V6's are a bit different from the pictured 3mm hot end. On the 1.75 mm, the tubing passes right through the heatsink and into the heatbreak.

None the less, the filament does look deformed near the drive gears. I would still check for a partial clog and rule that out.

Re: Stepper Motor softening PLA

I think I had about the same thing happen to me after I got my mk3 going. between the clip for the ptfe tube. I added a fan to the extruder motor.

I don't think I need the fan anymore BUT I keep it on for luck 😀

I have a Prusa,therefore I research.

Re: Stepper Motor softening PLA

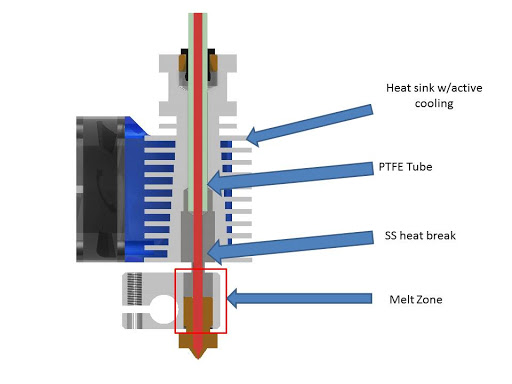

extruder set up is more like this on a 1.75mm v6 extruder

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Stepper Motor softening PLA

I was never able to reconcile the paint image (taken from from E3D's website, but maybe it's the Volcano version) and the actual short length of the stainless heat break. But I know there are E3D V6 clones that have longer PTFE, and now the Prusa GREEN DOT version, which is somehow different. This E3D V6 image shows the longer PTFE beside a V6 clone.