Silencing part cooling with PLA

When printing with PLA the part cooling fan runs at full speed most of the time and is way louder than everything else on that printer.

I aimed to come up with a more quiet solution. So I designed a cooler for an axial fan, since with this type there are much more quiet part available ( The other axial fan on my printer is hard to hear at all ) .

The air tubes are not yet designed well, nevertheless it already works quite ok, meaning that PLA with 60 degree overhangs come out quite nice.

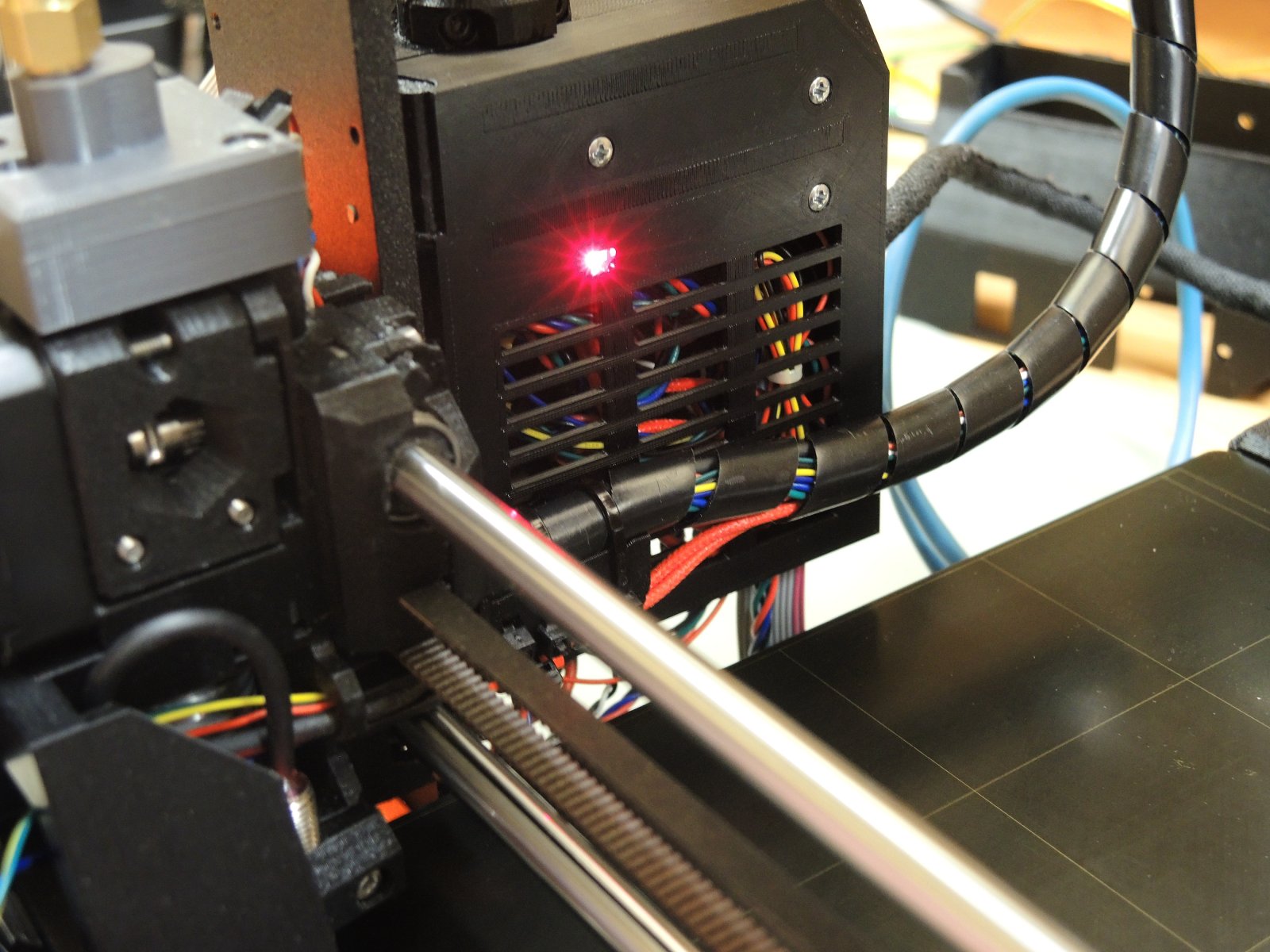

Right now the Sunon fan in the first picture is the only one I found so far with works with the 5 volt PWM signal from the board. Unfortunately it is not very quiet.

It seems that the biggest issue with this approach is that most fans which can deal with some form of PWM are available as 12V versions, but the printer delivers only 5 volt.

Re: Silencing part cooling with PLA

Perhaps a better approach would be to design an enclosure for the centrifugal fan (which provides a higher pressure needed for directing air downstream). Something than puts a barrier between the fan mechanics and the world. I envision a shroud that keeps the same basic fan position but redirects intake air from above -- similar to simply flipping the motor over so the intake is on the extruder side and enclosing the intake path to pull from above the extruder. Flipping the fan also fixes the thrust bearing issue of running the fan upside down - it isn't designed for that and adds to its noise.

ps: anything that is a barrier in front of and close to a fan blade creates an area of high pressure that makes a lot of noise when the fan blade passes over it. So all those dividers are noise sources. Better to move all those edges down 15 mm (the width of a blade).

Re: Silencing part cooling with PLA

Thanks a lot for that input.

Because of that, I did a few test, and found that with some fans i has a significant impact on the sound level and on the quality.

But my first, crude tests show that it can go in both ways, meaning it can get louder or more silent, and the tone quality can get more pleasing or more annoying, all depending on the type of fan.

I will look deeper into that, and do some more measurements.

Re: Silencing part cooling with PLA

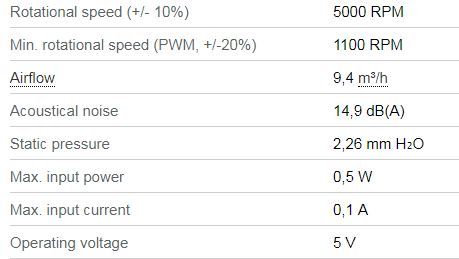

I'm in the middle of doing something similar but it will use the original Prusa part cooling nozzle. I've design a funnel that will hold a 40mm Noctua NF A4x20 fan, these are 20mm deep rather than the usual 10mm depth and are designed for high static pressure applications (as are blowers). The noise of the fan has bothered me since day one, and the bearings seems to be suffering after being operated at 45 degrees as the fan now rattles like mad when starting up.

I'm just waiting on the fan to arrive to test out the design, I haven't yet put the holes in the mounting flange and the final size of the funnel entrance may need tweaking.

Re: Silencing part cooling with PLA

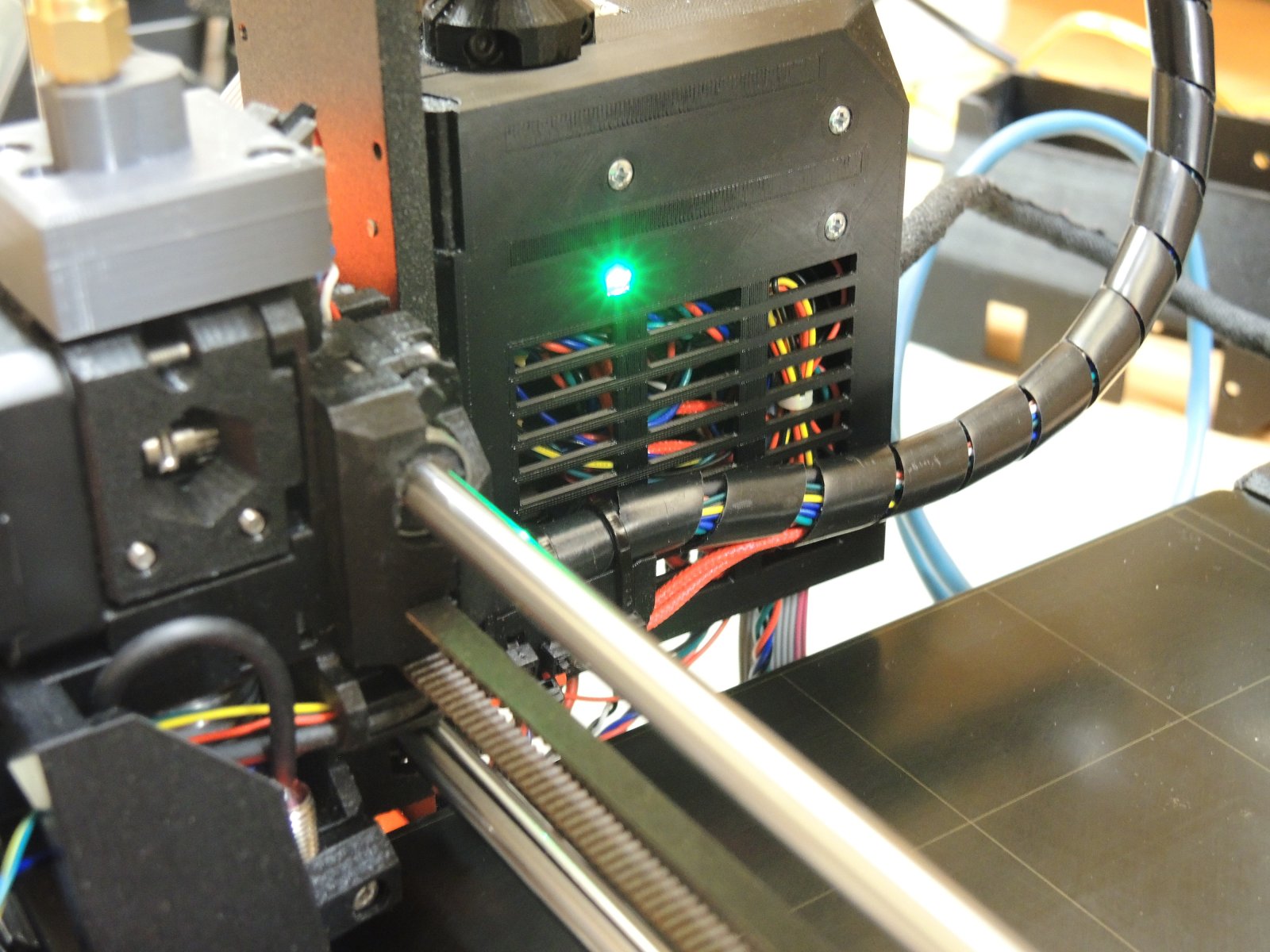

I offer this data that suggests the axial fans do not compare with the centrifugal fans for static pressure. The best Noctua 40mmx20 radial fan is in shut-off at 2.26 mm, but even the lowest power NMB 50mmx20 centrifugal fan is still moving about 2cfm of air.

Re: Silencing part cooling with PLA

There is no real need for a high static pressure for cooling itself.

The high pressure would just be needed to overcome air flow resistance, caused for eg. by edges or corners causing turbulences or narrow pipes where the air has to be pushed through.

Regarding the design with the funnel:

The funnel right behind the fan looks to me round without any corners or separators, this allows the fan to rotate the air behind instead of building up more downward airflow. I would recommend to try it at least with a square design where the fan is attached, to get enough flow through the old cooler.

Re: Silencing part cooling with PLA

A tube is a duct. If the fan moves air, which it will, there will be a higher pressure behind the fan, lower pressure outside the duct, air will flow, not spin. Heck - if this "spinning air" were a problem a fan would never work in the first place. Adding to the fact pressure differences is what moves the air, a higher pressure is required to get the air to compress at a point of choosing, like the nozzle and filament.

Re: Silencing part cooling with PLA

Maybe that video shows better what I meant:

Re: Silencing part cooling with PLA

I see what you are saying, but question the effectiveness. I don't have modeling software here, and I am not a turbine designer, but pretty sure all the stator in the video is doing is "aiming" the air flow. Think laminar vs chaotic flow. Without the stator the air is coming out of the cone at all angles, and a bit irregular. The stator restricts the air, and smoothes the flow into a more uniform direction and rate, exchanging pressure and velocity. Think of a garden hose nozzle changing from open flow (maximum flow), versus a fan shape or stream (smaller area and flow).

Bottom line, the angle of the pressure front is different; but flow rate and energy are also lower. Redirecting a stream also wastes more energy so other shapes after the stator/cone are less effective. One would hope whoever designed the fan shroud accounted for velocity and pressure changes along the way. And remember that heat exchange is mostly about mass: more air moving past what you are cooling is better.

If it were possible to focus the same air flow to a pin point, like a compressor and air gun, or pippet on a can of air, and have it pointed just below the extruder nozzle, you could get maximum cooling at the ideal location it's needed. Plus you'd get the benefit of the natural compression/expansion heat exchange. But we'd have very noisy printers. For now, the accepted optimal solution seems to be is moving lots of air past the nozzle, directed in a way it doesn't cool the hot end yet cools extruded plastic, regardless of print direction. I'll note the Mk3 fails to cool behind the nozzle as well as it could.

Re: Silencing part cooling with PLA

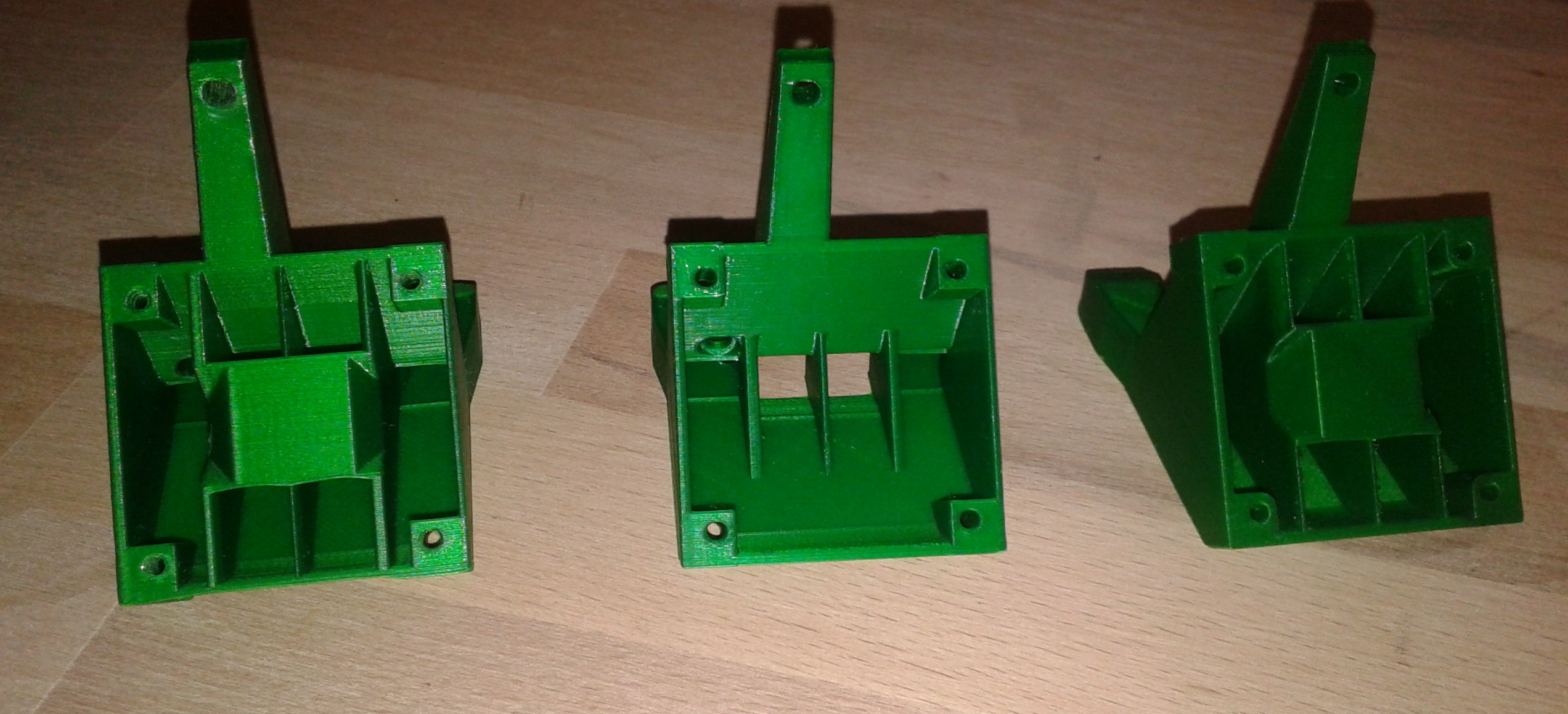

Some time ago I got a Noctua 40x40x20 fan:

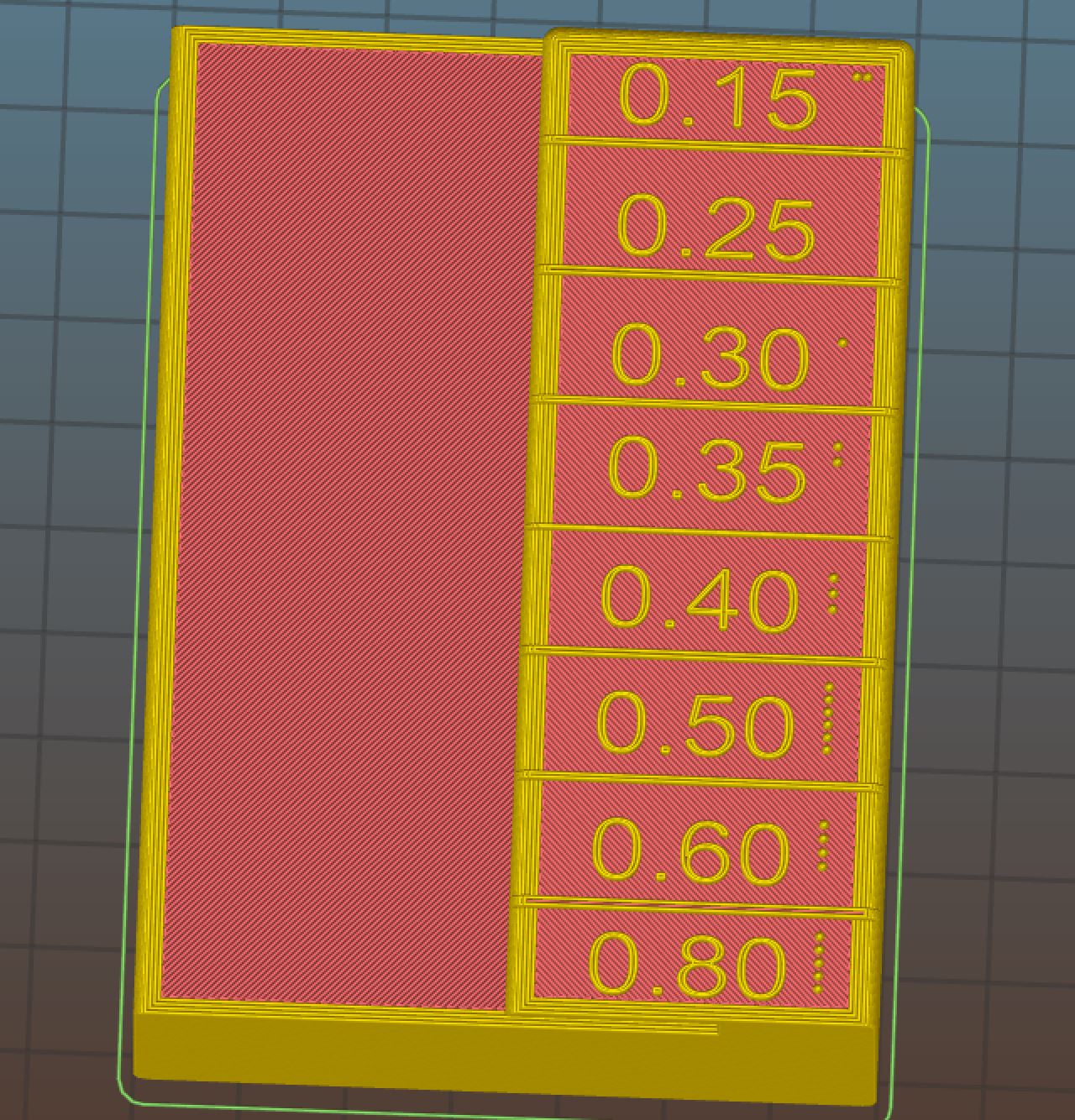

Overhang-Tests:

The nocuta-fan on 100% is more silent than the sounds form axis movements in "Silent Mode"

I did more than 20 prints with PLA, the print quality is nearly the same as with the original cooler design with the turbo-fan.

And the sound level is just way more silent.

The silver overhang-test up on the left was printed with the original mk3 part cooler.

The green one with the noctua-fan. Both with Prusa-PLA. They are turned upside down on the photo.

The green one has a bit of a flaw at the edge where the overhang is 55°

I haven yet really optimized the air outlets, so I find it astonishing that it already performs so well.

This nocuta-fan has problems to deal with a PWM-signal less than 100%, like most 5V fans.

I got the info from prusa-support that the PWM-frequency will be changed in the upcoming firmware release.

So maybe this improves that.

Re: Silencing part cooling with PLA

Hello Rene,

nice idea, I did the same experiment a few months ago using Noctuas 4-Pin PWM Fans with an special adapter. It stayed with a try. It is just enough for simple objects. But even with the Benchy there are problems, depending on the printed orientation of the Benchy.

For a sufficient all-round ventilation you need at least 2 of these fans, blowing from different sides.

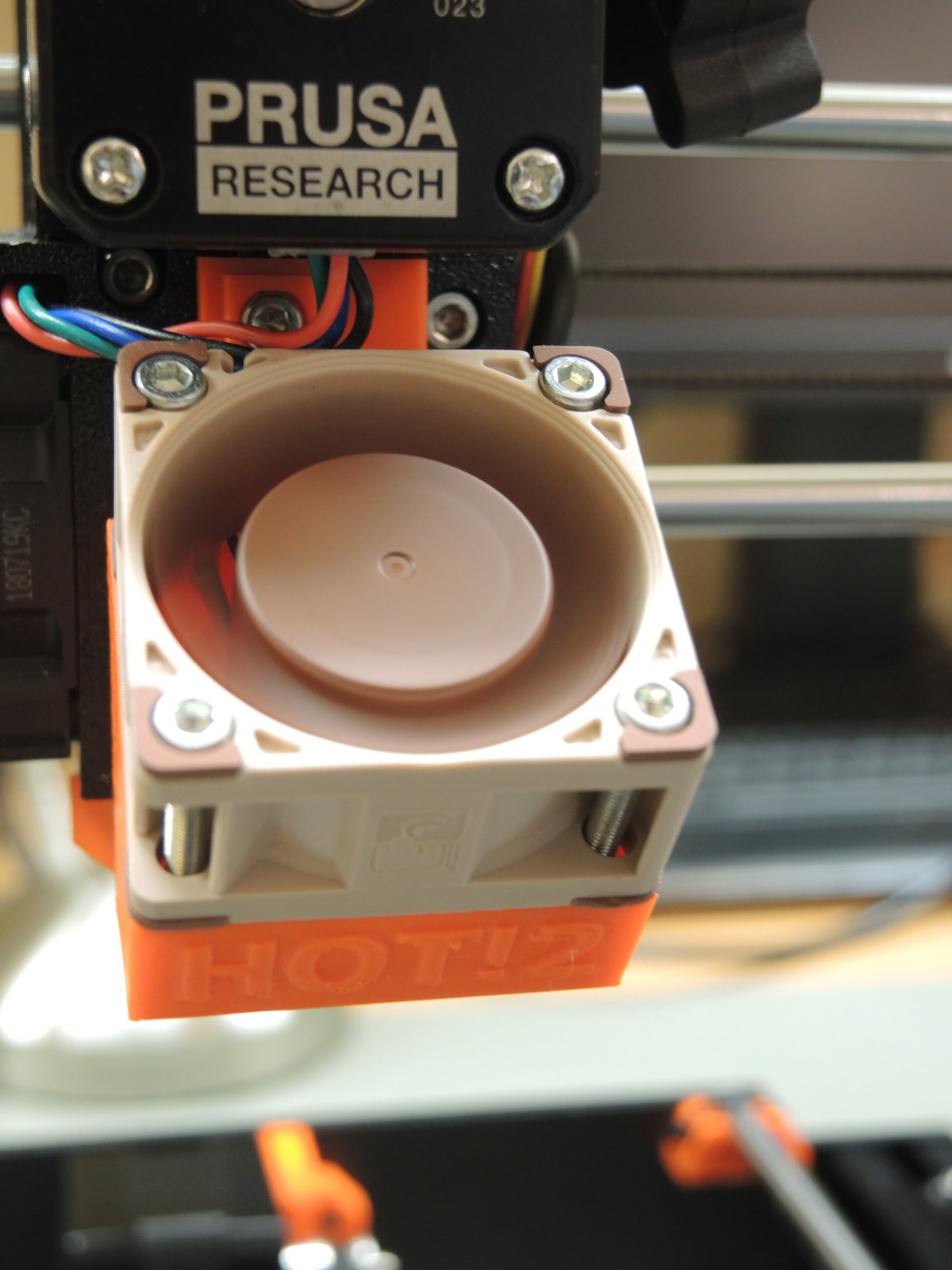

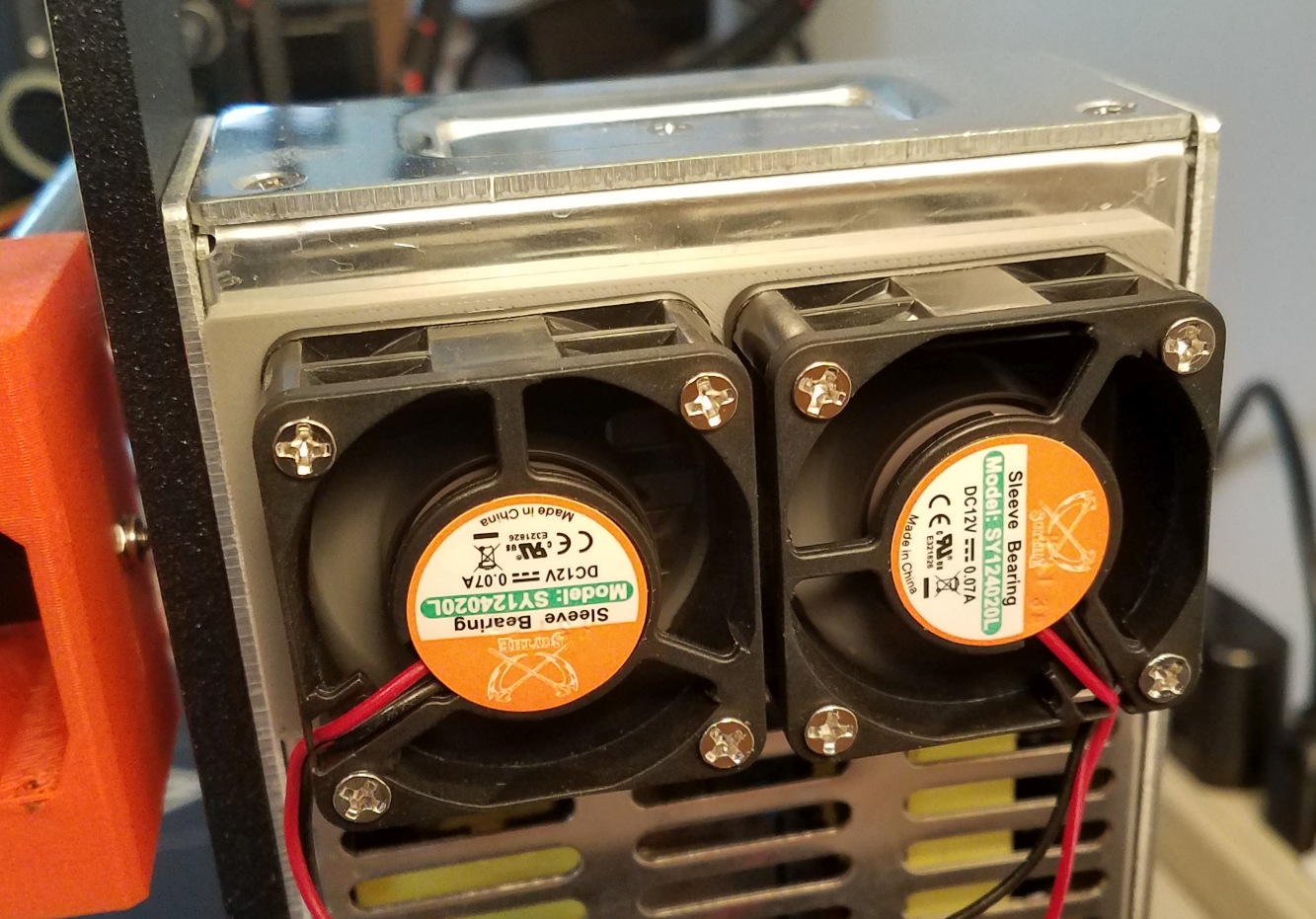

So I switched to a 24V PWM-Blower fan and developed a fan control unit, using a MCU, which I placed in the door of the Einsy case. This works for all PWM (4-pin) fans from 5V..24V and up to 25KHz PWM frequency. No more whining noises and the speed of the fan now runs linearly from 2% to 100% of the driving PWM signal. The now connected 24V PWM fan operates at 25KHz, which is no longer heard. The air pressure of the 24V fan has doubled to the original Prusa fan, so that 80% PWM are easily sufficient for PLA. No more 5V use of the Einsy board, since the power supply is now completely from the 24V (5V to 24V, fan dependend).

Additional LEDs indicate the operating status and also faults.

This works perfectly for me for several weeks now, using the RHDreambox - air-nozzle (thx) https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/playing-with-the-air-nozzle-design-t25642.html .

Some Pictures:

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Silencing part cooling with PLA

Hi Holger

What is the noise-level now in comparison to the original design?

Thanks for all the information. I was also thinking about 4-pin fans.

Did you try to connect them directly to the pwm-signal without adapter and just additional 24V ?

Re: Silencing part cooling with PLA

I offer this data that suggests the axial fans do not compare with the centrifugal fans for static pressure. The best Noctua 40mmx20 radial fan is in shut-off at 2.26 mm, but even the lowest power NMB 50mmx20 centrifugal fan is still moving about 2cfm of air.

Capture.JPG Captureb.JPG

My design was a disaster, the airflow seems to be choked in the funnel as I can feel backflow above the fan (the fan is deffinitely spinning in the right direction). It seems the fan is pushing air into the funnel but somehow the air is then coming back out between the fan blades and the fan casing as there is a slight gap..

Re: Silencing part cooling with PLA

So I switched to a 24V PWM-Blower fan and developed a fan control unit, using a MCU, which I placed in the door of the Einsy case. This works for all PWM (4-pin) fans from 5V..24V and up to 25KHz PWM frequency. No more whining noises and the speed of the fan now runs linearly from 2% to 100% of the driving PWM signal. The now connected 24V PWM fan operates at 25KHz, which is no longer heard. The air pressure of the 24V fan has doubled to the original Prusa fan, so that 80% PWM are easily sufficient for PLA. No more 5V use of the Einsy board, since the power supply is now completely from the 24V (5V to 24V, fan dependend).

Additional LEDs indicate the operating status and also faults.

This works perfectly for me for several weeks now, using the RHDreambox - air-nozzle (thx) https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/playing-with-the-air-nozzle-design-t25642.html .

Excellent idea, do you have any further details? I'd love to run a 12v Sunon centrifugal fan with a magnetic bearing rather than the cheap and nasty Prusa fan with a bush arrangement. My printer is only 2 months old and the fan sounded horrible (lots of rattles, replaced with no questions by Prusa), but I really question the usage of a fan with no bearings at a 45 degree angle. It will always lead to premature shaft wear and failure.

Re: Silencing part cooling with PLA

Hallo Rene,

hello David,

the fan used by me is a custom made ball bearing type with 30mm H2O static pressure and a speed range from 140 rpm to about 7000 rpm. Since it is a 4-pin PWM fan, it can not be used directly on the printer, and it needs a suitable controller, but at least an additional GND cable and an inversion of the driving 5V PWM signal. In order for the speed to be linear with the driving PWM, an MCU is an advantage. In addition, the LED controlled by the MCU always provides information about the correct fan function. The fan power is supplied directly from the PSU. The fan voltage should therefore match the voltage of the PSU, if you do not want to install additional voltage regulator. Operation with 5V would also be possible, but is not recommended because of the lower fan performance. For my MK3 I have a 24V type installed, but 12V would also be possible for a MK2.

It is a typical fan noise to hear, little disturbing, depending on the speed similar to the Prusa fan in the healing state. Especially nice for people like me, who print with less than 100% PWM. At 50% it's nearly noiseless, like the Noctua one.

Greetings, Holger

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Silencing part cooling with PLA

Did you really mean 30 mm of H2O ? That's pretty amazing for a radial fan. The best Noctua commercially available provides only 2.26 mm H2O static pressure.

Re: Silencing part cooling with PLA

Hi Tim,

yes, 30mm H2O and about 4.x CFM is correct. Prusa's radial fan (5V) makes about 12-15mm H2O air pressure (@ 5000 RPM). This is normal for these fans and the main difference to axial fans. These generate more air, as far as they do not have to generate air pressure. So do not have to blow through a nozzle against a component. The air flow then breaks off quickly.

Therefore, radial fans are the best choice for a 3D printer, especially in the PWM version, which can then be optimally controlled in terms of speed.

A suitable controller may then establish a linear relationship between the percent PWM and the percent fan speed. This is typically not in a linear relationship, design conditioned and depending on the age and degree of pollution.

greetings Holger

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...