Re: Scratched rods from linear bearings

The Y-axis bearing mount with the U-bolts can be easily overtightened, leading to stuck bearing balls that are no longer rolling but sliding.

So yes, it is possible that you tightened the bolts too much, bent the linear bearing and scratched the rods.

In your photo it looks like the hardened layer of the rod actually broke away.

Talk to support if they can help you with new parts, or get them from a rod & bearing supplier. If you are in the US you are lucky and can buy high quality ones from Misumi.

Nevertheless, that U-bolt still needs to be itghtened very carefully. I recommend sliding the Y-axis assembly back and forth, and checking for play and friction. Just tighten the bolts until the bearings don't move any more when you try to wiggle. If you tighten the bolts just a little too much you can clearly feel the friction increasing.

I do wonder why Prusa don't change the method of attaching the bearings to the bed frame... the instructions to tighten the nuts on the provided hoops is very prone to being misunderstood by folks with little experience of assembling mechanical items and the instruction to use the needle nose pliers to tighten them is only making maters worse... I read all the time here and on the owners facebook page of Prusa sending replacement bearings and rods due to this problem... I think it could be solved if Prusa just redesigned the bearing holder sop it could not crush the bearing shell if it was over tightened... I see several user designed mounts on thingverse and I assume that Prusa does not use something like those is to not impact the Z envelope as the wire hoops are about as thing as you can get. perhaps if the mounts were cast/ machined into the frame it could be done but that would be expensive...

Re: Scratched rods from linear bearings

I fully agree with Randolf.

Actually I tried using such bearing holders with my MK2 before I sold it, but they didn‘t fit the holes in the aluminum frame so I had to stick to the U-bolts.

Re: Scratched rods from linear bearings

Randolf, your comments describe the problem and the only true repair.

Re: Scratched rods from linear bearings

The other way to avoid crushed (or even just distorted in a way that the builder might not notice ) bearing shells is to attach them with a torque driver to a one newton meter (10.3 inch pounds). but that is a tool that not many kit builders will have and expecting them to buy one for about $40 is not going to fly with the marketing folks at Prusa. Used my torque driver to assemble my kit and so I recommend it to a serious builder who is not going to stop at one. but they could include one of these sized for the nuts in question . at little cost

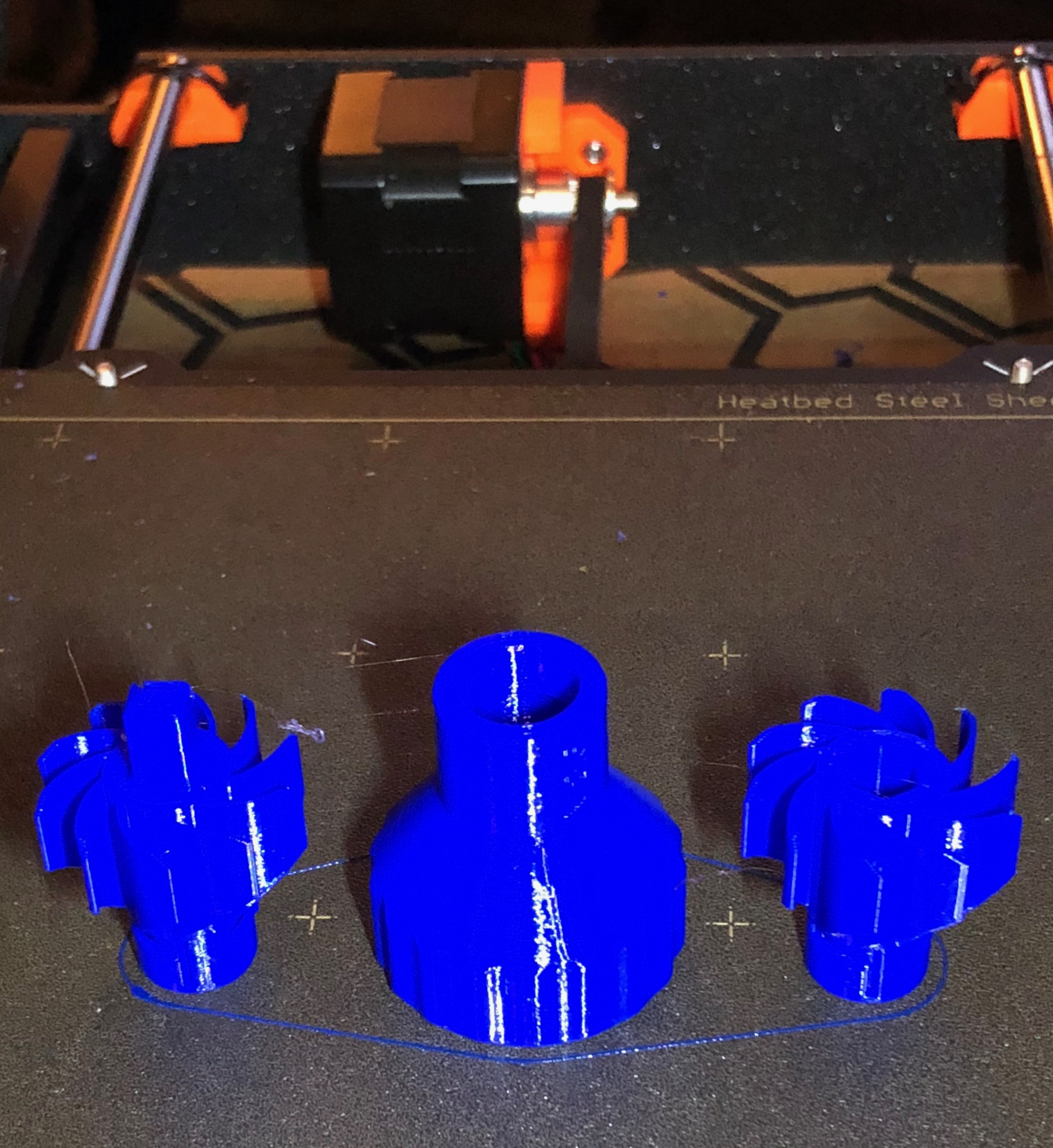

I printed this one to test.

this driver is created at a nominal 10 inch pounds and I have made one out of PLA . and checked then against a high accuracy torque wrench of my neighbor the auto mechanic and one made of Prusa sliver that came in the kit clocks in at 10 inch pounds exactly.

there are several areas where working to a known torque in assembling a MK3 kit provides an improved result... these printed drivers are found on thingverse in several settings attaching the heated bed to the frame is another one

https://www.thingiverse.com/thing:2613057

this is slightly different from the one I found and printed it was recommended for seating a e3d nozzle against the heartbreak in a heated heater block.

Re: Scratched rods from linear bearings

Well, I can now add myself to the list of people with scratched rods. 🙁 I haven't fully inspected things or tested to see which kind of rods I have as the printer is busy doing its thing. A quick look between prints makes me think it might be my own fault. I only saw a grove on the left rod, which makes me think that I may have over tightened one of the left bearings. If I did, then the bearing are exceedingly easy to destroy. While I did not use a toque wrench to tighten down the nuts, I stopped tightening the moment that there was no longer any play between the bearing, U bolt, and carriage. While it doesn't mean I don't make mistakes on occasion, I build model aircraft as when as other small mechanical things. Over torquing a steel bolt in an aluminum crank case is an expensive mistake (I do have several torque wrenches), so I tend to be careful and aware of such things.

As I noted, the printer is busy printing and figuring out the cause and extent of the damage will require taking the printer offline and partially disassembling it, which I dont' care to do at the moment. I rotated the scored rod about 15 degrees in the hold to put new rod surface under the contact points of the bearings. If, it scored the rod again, I'll rotate again. At some point, I'll replace the rod(s) and bearings. But, for the time being, it's not worth taking the printer down.

Re: Scratched rods from linear bearings

My rods were scratched up as well, just ordered new bearing and rods from Misumi, and plant to install these bearing holders and not use the U bolts:

Re: Scratched rods from linear bearings

I did a bit of checking in between prints, and the scoring on my left Y rod is completely overlapped by the travel of both linear bearings, so I can't point to either bearing and say "this is the bad one". I also found one of my sets of neodymium magnets. All my rods, including the scored one are highly magnetic for what its worth.

Re: Scratched rods from linear bearings

My rods were scratched up as well, just ordered new bearing and rods from Misumi, and plant to install these bearing holders and not use the U bolts:

https://www.thingiverse.com/thing:2823171

/!\ They are not compatible with original Prusa i3 MK2(s), MK2.5 or MK3!

you have to use them as part of rather extensive bear upgrade it seems.

Re: Scratched rods from linear bearings

one would think it was last longer then mine did (07/17/2018) but my speed could have been apart of it.

I have a Prusa,therefore I research.

Re: Scratched rods from linear bearings

My rods were scratched up as well, just ordered new bearing and rods from Misumi, and plant to install these bearing holders and not use the U bolts:

https://www.thingiverse.com/thing:2823171

/!\ They are not compatible with original Prusa i3 MK2(s), MK2.5 or MK3!

you have to use them as part of rather extensive bear upgrade it seems.

did not see that but there are many on thingiverse:

https://www.thingiverse.com/thing:3009203

https://www.thingiverse.com/thing:2992409

and if I have to I'll design ones myself, but I will not use those U bolts again 😀

Re: Scratched rods from linear bearings

lucky it seems swapping the rods out and rotating 15% seems to help while waiting on new shafts. didn't take too long. 2 zip ties and 16 screws to swap all shafts

I have a Prusa,therefore I research.

Re: Scratched rods from linear bearings

I've been using a modified version (beefed up the thickness for the screws) of the right strap, non-bushing here: https://www.thingiverse.com/thing:1819779

They've been installed for a few months and are working very well. I'll try to remember to upload the remix version tonight if anyone is interested.

The original works well too but there wasn't much meat for the screws to bite into and at least one wouldn't stay tight.

EDIT: Uploaded the remix this eve: https://www.thingiverse.com/thing:3214732

Re: Scratched rods from linear bearings

Well, add me to the list. Two weeks after receiving my assembled printer I have scratches on the top rail of my x axis... This thing is brand new and I've hardly put any filament through it. I'll contact prusa and also order the rods and bearings in case the replacements don't work. I'm just a little worried about putting it back together. I've read horror stories of measuring and alignment when swapping the smooth rods and bearings. Am I I just being overly worried? Is it that hard? Are there any helpful videos or instructions anywhere on how to do it?

Re: Scratched rods from linear bearings

it shouldn't be that bad. just gotta be extra careful with the heat bed bearing with the dumb u clamps.

I have a Prusa,therefore I research.

Re: Scratched rods from linear bearings

it shouldn't be that bad. just gotta be extra careful with the heat bed bearing with the dumb u clamps.

Thanks! I just got done talking with support and they're going to send me new rods and bearings but I also just purchased the misumi's, if I have it apart, I'm fixing it with something better. It's crazy that after only two weeks there are scratches in my rods and a couple bearings are shot, ON A PRINTER I DIDN'T EVEN ASSEMBLE! lol Support said with the MK3 there's no measuring or alignment, is that correct?

RE: bed bearings, are there any good alternatives to the u clamps that have been tested and for sure work for a long time?

Re: Scratched rods from linear bearings

ya, and to think if the people that got a kit ask for new rods, they say we put it together wrong....

things universe has a few that should work. I'm looking into a hiwin linear rail system for my MK3. I think I can mod it semi easy. those hiwin bearings are cool.

I have a Prusa,therefore I research.

Re: Scratched rods from linear bearings

it shouldn't be that bad. just gotta be extra careful with the heat bed bearing with the dumb u clamps.

After only 4 months I had the both of the Y rods (bed rods), 1 Z rod and 1 X rod scratched badly. so the X & Y had nothing to do with the U bolts. Cheap A$$ bearings if you ask me.

Re: Scratched rods from linear bearings

I don't feel so bad now. seems to be 2 weeks or 4 months, at least I don't think I'm overtightened the u bolts at this point. just the timing of mine was craptastic. my MMU is almost here, and my PQ issues will slow down my MMU install damnit... at least they shipped the other parts I ordered in the same box. so while I'm replacing all my bearings I will have to look at my mmu.

I have a Prusa,therefore I research.

Re: Scratched rods from linear bearings

I just did some maintenance to my MK2S and noticed that my X-axis lower rod is scratched badly, deep deep grooves all the way through coating. 😯

Turning the rod some 20 degrees fixed the problem but still. Could feel the grooves easily with my fingernail. No idea if that has affected print quality.

Other rods are pristine. Maybe my only "bad" bearing is the one on extruder carriage? 😀 If the bearings are causing this.

Decided to order Misumi bearings and rods... Lets see how that goes.

My printer is about 13 months old, KIT and it has about 88 days of printing behind. Its my precious printer and its devastating to see it being hurt! 😆 😆

Re: Scratched rods from linear bearings

I just did some maintenance to my MK2S and noticed that my X-axis lower rod is scratched badly, deep deep grooves all the way through coating. 😯

Check with a magnet.. Is that rod different to the others...