Raising Max Bed Temperature to 150c

Hi All,

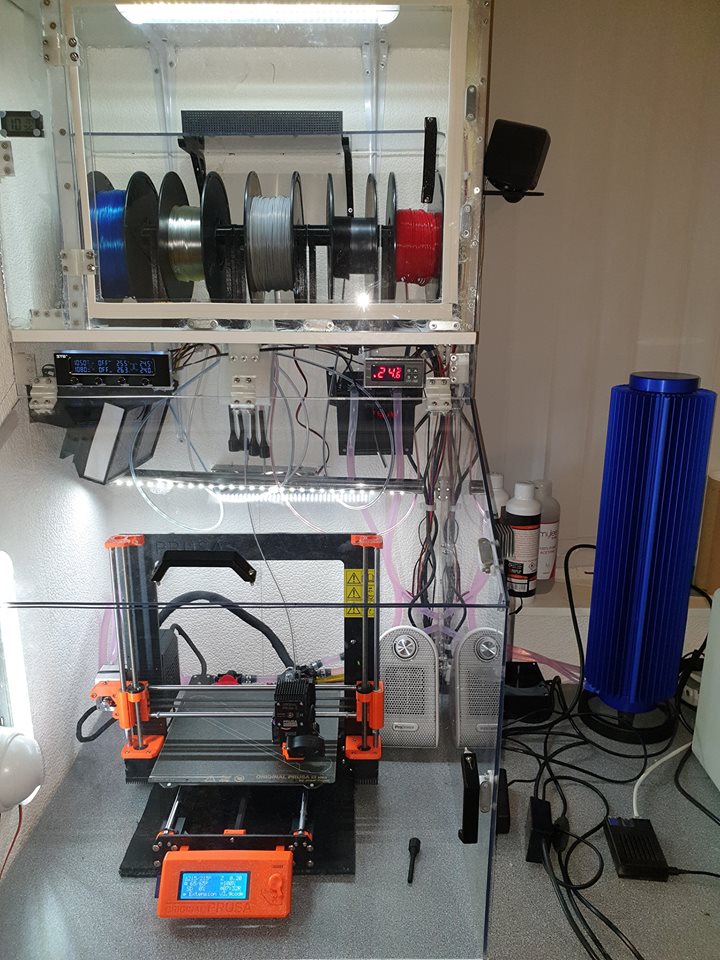

I'm looking into creating some custom firmware so that the bed can be heated up to 150c.

Now assuming it will actually reach such a temp (in an enclosure which can be temperature controlled to reach 70c so I think it has the power with a high ambient assisting) will there likely be any issues with the bed itself at such temps (ie magnets failing\falling off etc)?

I'm just finishing off on a full set of pure PC printer parts so the plastics on the printer shouldn't be a problem at these temps (electrics are already sorted apart from the einsy and LCD which will be done next).

Before the why comes up i'm wanting to print some fairly substantial PC parts for car use (both wide and high) and while at 120c bed temps smaller parts are ok anything sizable will start to warp, adhesion on the textured plate is excellent with 10mm brim on the profiles I've cobbled together (so much that it's starting to flex the steel sheet rather than lift off sometimes). Also as the print gets taller the layer adhesion is dropping off as the heat transfer through the part from the bed is dropping off and I need these parts to be pretty strong and with a 30c boost on the bed it should assist that.

Thanks in advance for reading\commenting,

Mike

Re: Raising Max Bed Temperature to 150c

At 70c ambient, you're going to have other problems beyond keeping the bed warm. The electronics will be above rated operational spec, and even if you move the power supply and electronics outside the enclosure, the motors will be running hot, and may be outside their SAO.

Also most Neodymium magnets are spec'd at just over 100c.

You're in for some work.

Re: Raising Max Bed Temperature to 150c

Now assuming it will actually reach such a temp (in an enclosure which can be temperature controlled to reach 70c so I think it has the power with a high ambient assisting) will there likely be any issues with the bed itself at such temps (ie magnets failing\falling off etc)?

You're on the cutting edge what might work for some time. But most of the parts will exceed temp. rating so will fail pretty fast.

In case of bed it's easy to check. Put your bed in the oven with 160C and let it there for couple hours. See what's happening 🙂

I'm pretty sure some things will get soft. Like glue and painting. PC glass transition is around 150C, so expect the cable holder to deform as-well. Haven't read somebody tried that so far. I'm looking forward to see your results 😀

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Raising Max Bed Temperature to 150c

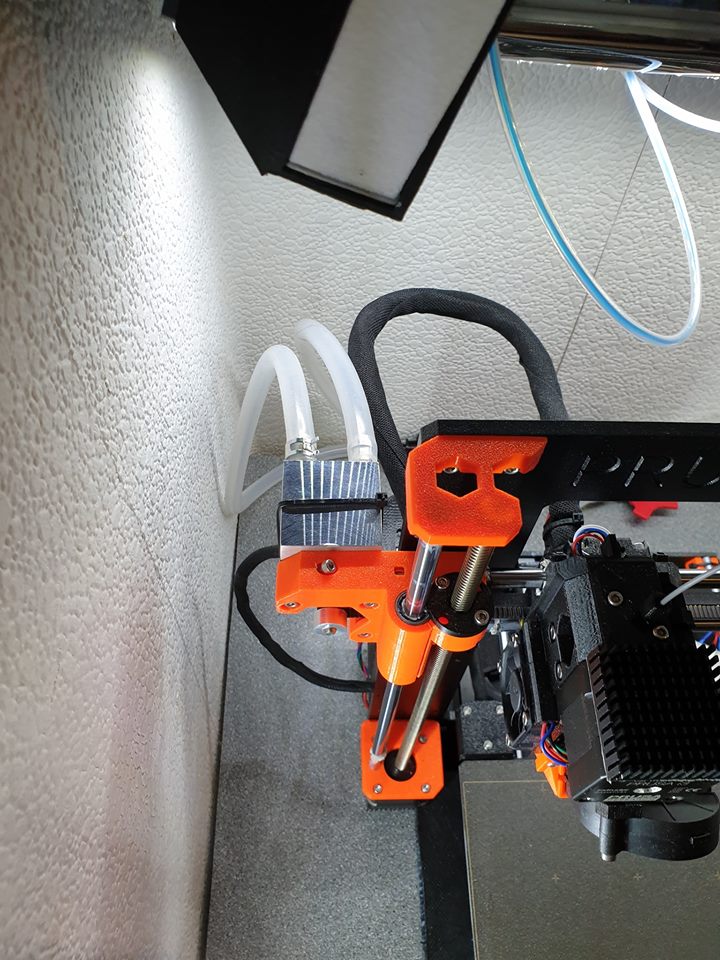

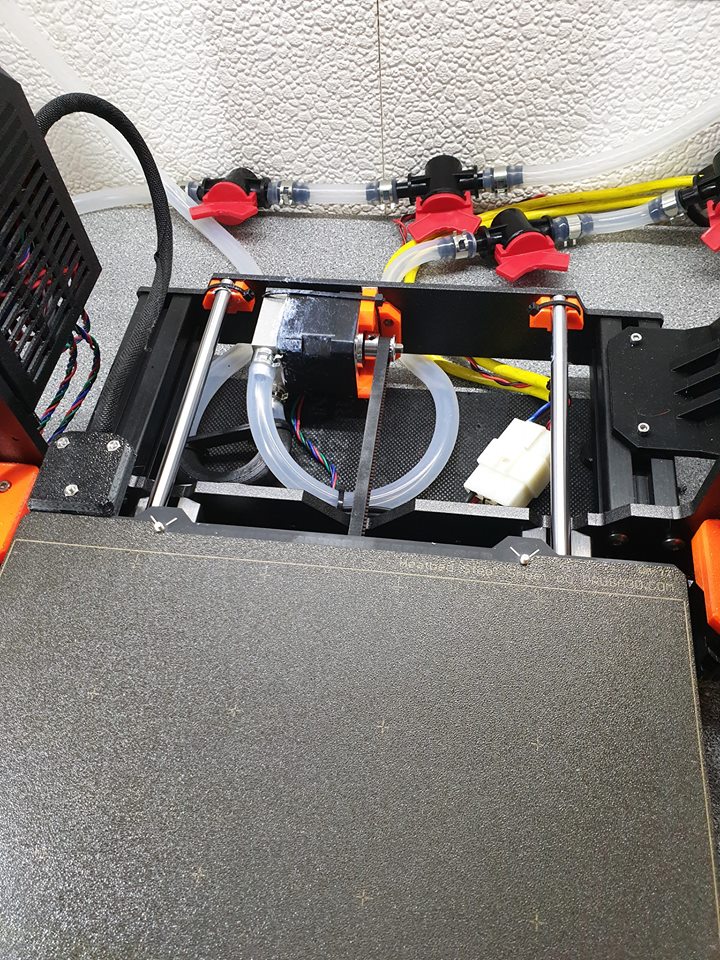

Thanks for the replies, after some more research i'm pretty sure the magnets are good to 150c (being the SH spec ones). For electronics I already have water cooling for the X and Y motors and making up a fan shroud to use the hot end air flow to blow over a heatsink on the E motor (also i've found the general air wash from this fan can cause PC to warp so redirecting it is going to help). The Z motors don't really get very much above ambient anyway so have just added heatsinks to those, if they are getting much above 85-90c then i'll make the cooling active through extending the water cooling or adding some fans to the heatsinks.

PSU is already outside, looking into how best to relocate the einsy (although I may add a cold air feed\exhaust and fan to a new sealed einsy case rather than move it) and may do similar to the LCD panel.

Re: Raising Max Bed Temperature to 150c

I'm in the the exact same boat as you. I'm partway through converting all plastics to PC, I have an enclosure with an uprated power supply thats mounted externally (Einsy and LCD soon to follow), and I'm working on adding heaters. I also have the PT100 and high temp E3D upgrades. My end goal is to print with PEEK.

Questions:

What are you using for water cooling the steppers?

Have you gotten the firmware to successfully run the bed above 120C? I changed BED_MAXTEMP under configuration_prusa.h, which let me set the temp to 150C via the display, but it gave an ERROR MAXTEMP at around 125C when I tried to run it up that high. There's clearly some other bits of code that need to be changed, but I haven't been able to figure out which ones and where.

PS: You'll probably want to swap your printer parts to something higher rated than PC once you're able. I'm just using it as a stepping stone until I'm able to print Ultem 1010, at which point I'll reprint everything in that, then start on PEEK, and repeat the cycle.

Re: Raising Max Bed Temperature to 150c

Hiya,

I had an old Zalmann Reserator setup used for one of my PC's acting as the Radiator\Pump. This runs directly off 240v so there wasn't any need for an extra 12v supply feed. The cooling blocks are just some cheap 40mmx40mmx10mm ones from ebay, just tie wrapped on to the top of the X motor and to the side of the Y motor with thin tie wraps (want to upgrade to proper clips eventually but they have been so stable just zip tied haven't bothered to mess yet.

Was awaiting a good 7x7 Prusa firmware to appear before starting on the mods for the bed temp so haven't spent much time on that as yet (with the current RC out shouldn't be long hopefully).

Have all the structural plastics printed in PC now ready to swap out when I have time, still need to sort the LCD and Einsy cooling.

Making a fairly sealed new case for the Eisny that will use a fan in and fan out so that the same cool volume of air is pushed in and hot air pulled out (obviously within reason due to differences in fan tolerances and air density variation (and adding some heat sinks to the drivers). Using 2 small fans as it's going to be very hard to seal it in properly completely.

For the LCD will likely just add a lift off cover\fan (with ventilation through the desk surface below) to allow cool air in that area without impacting on the enclosure temp.

I wanted to still be able to get the printer out without too much messing about if needed, the PSU is a connector extension so can be put back in stock position quickly and the water cooling blocks can come off without needing to disconnect any water piping.

Found that the hot end fan air wash affected the PC prints on the left side so made a temp cover to ventilate the air upwards away from the bed and it was much better, For the final setup going to use a high flow 40x40x20mm Sunon which will be top mounted and act as a cooler for both the hot end and also flow air over a heatsink on the Extruder Motor.

Cheers,

Mike

RE: Raising Max Bed Temperature to 150c

Hello guys,

Any updates on the projects? Would be interesting to see how it went and what to expect for myself:)

RE: Raising Max Bed Temperature to 150c

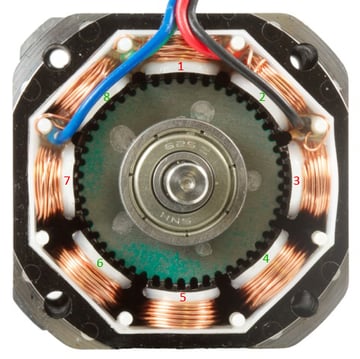

Sticking the cooling on the rear of a stepper motor is probably the worst place you could put it.

In the picture below, see all that air space, your not going to be cooling the body of the motor well at all. The end cap is a cover for the wiring and mount for the bearing, the heat is generated in the windings.

You need to be cooling the metal laminated parts i.e. the sides. Look for something like northbridge cooling or MOS cooling blocks, there used to be lots of small ones like this available for PC cooling of motherboards.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Raising Max Bed Temperature to 150c

To everyone who is going to do some kind of high temperature printing, I'm attaching some scientific approach from NASA experiments with low-budget FDM machines and high-temp upgrades to print ULTEM.