Problems ejecting filament/inconsistent extrusion

Hi,

I've suddenly started experiencing a strange issue with my MK3.

When the printer is at PLA temperature it will no longer eject filament, sort of pushes up a few mm and then gets stuck, loosening the tension bolts on the extruder allows me to pull out the filament.

The other thing that started happening at the same time, is that the printer will print normal layers until about 15 minutes in, and then start to barely extrude anything, it finishes the print but layer adhesion and faces are very poor.

Wanted to see if you guys had any insight on this before I went taking things apart.

Re: Problems ejecting filament/inconsistent extrusion

Two common problems:

1) There is a known issue with the Bondtech gear door shaft being too short and not connecting on both sides of the door. Test by opening the door and pressing on the idler gear. It should roll easily but not "give" or flex. If it flexes, check the idler shaft is visible in the holes in both "ears" ... if the shaft is flush on one side, it needs adjustment. Or it may be the tension screws may not be set properly.

2) Nozzle plugs are pretty common. A cold pull or two usually fixes things. This also fits with the tough filament removal. A plugged nozzle will cause filament to fill the backside of the nozzle and the area and up into the heat break. This area is wide enough the "jammed filament" is larger than the PTFE, and a moderate force is needed to pull it up through the tube.

If this answer is off base, a photo of the bad print can help point out the issue.

Re: Problems ejecting filament/inconsistent extrusion

Two common problems:

1) There is a known issue with the Bondtech gear door shaft being too short and not connecting on both sides of the door. Test by opening the door and pressing on the idler gear. It should roll easily but not "give" or flex. If it flexes, check the idler shaft is visible in the holes in both "ears" ... if the shaft is flush on one side, it needs adjustment. Or it may be the tension screws may not be set properly.

2) Nozzle plugs are pretty common. A cold pull or two usually fixes things. This also fits with the tough filament removal. A plugged nozzle will cause filament to fill the backside of the nozzle and the area and up into the heat break. This area is wide enough the "jammed filament" is larger than the PTFE, and a moderate force is needed to pull it up through the tube.

If this answer is off base, a photo of the bad print can help point out the issue.

Thank you for the response, your answer is definitely on base 🙂

1. I undid the door and checked out the idler gear, there is no give at all and it does spin freely. The shaft is sticking into both "ears" on the door, however it was still flush on one side, I pushed it in slightly just in case. As far as the tension on the screws go, I had them set to where the head was basically flush with the body of the extruder when there was no filament loaded, I wasn't completely sure how to tell if it was too tight or too loose but extrusion at first was normal with that tension if that helps.

2. Unfortunately I worked long hours today and got home late and due to noise and where my printer is located I can't run it at late hours. I will attempt a couple of cold pulls in the morning as well just to see if that helps sort it.

I thought I might include a couple of images just in case, however I'm sure can't really move forward until cold pulls are performed and also to test if adjusting the gear did anything.

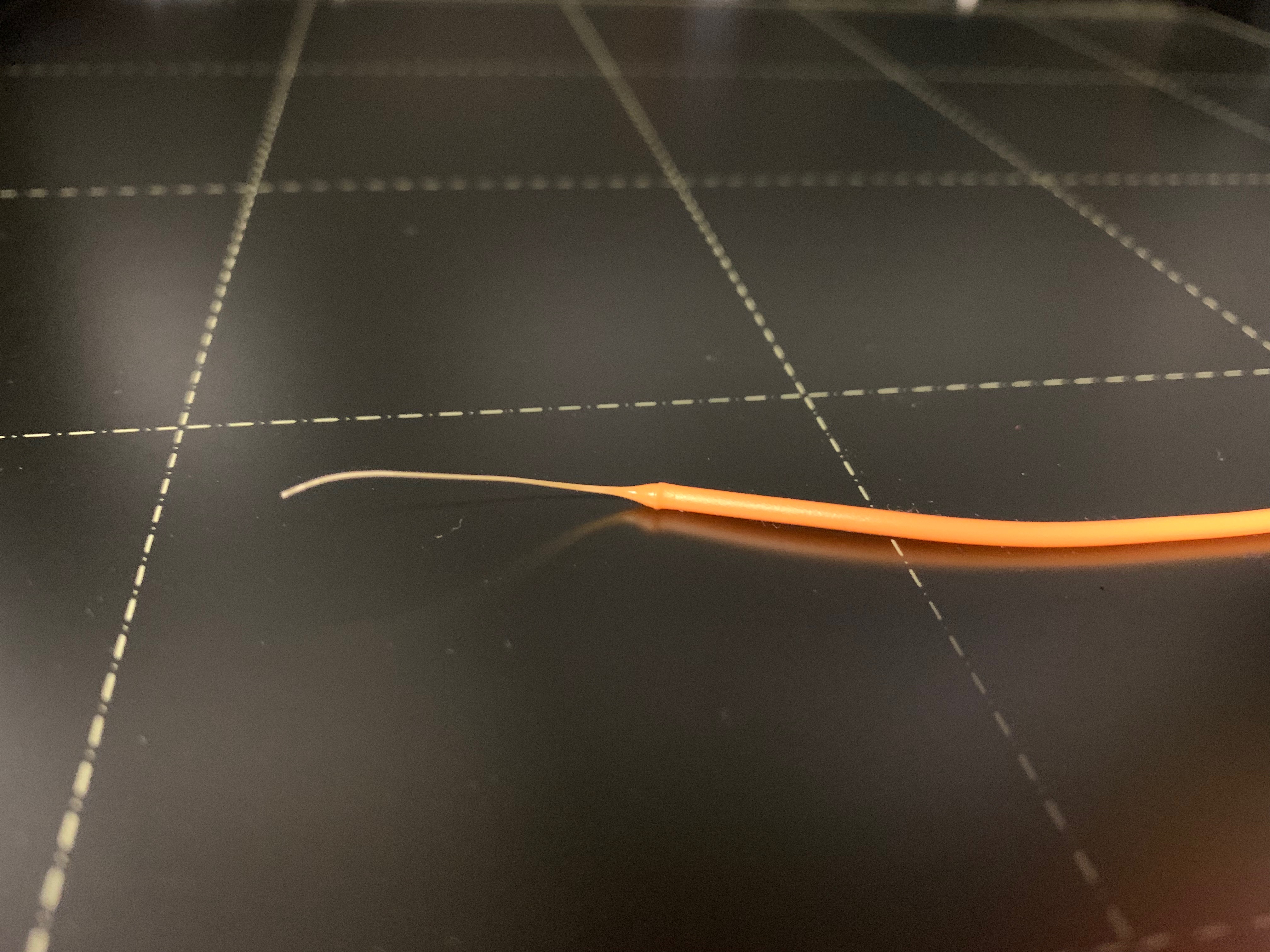

This first image is a section of filament that got stuck in the extruder upon jamming. There is sort of a small blob on the end of it that would have needed to pass through the PTFE tubing, like you noted perhaps this is pooling due to clogged nozzle.

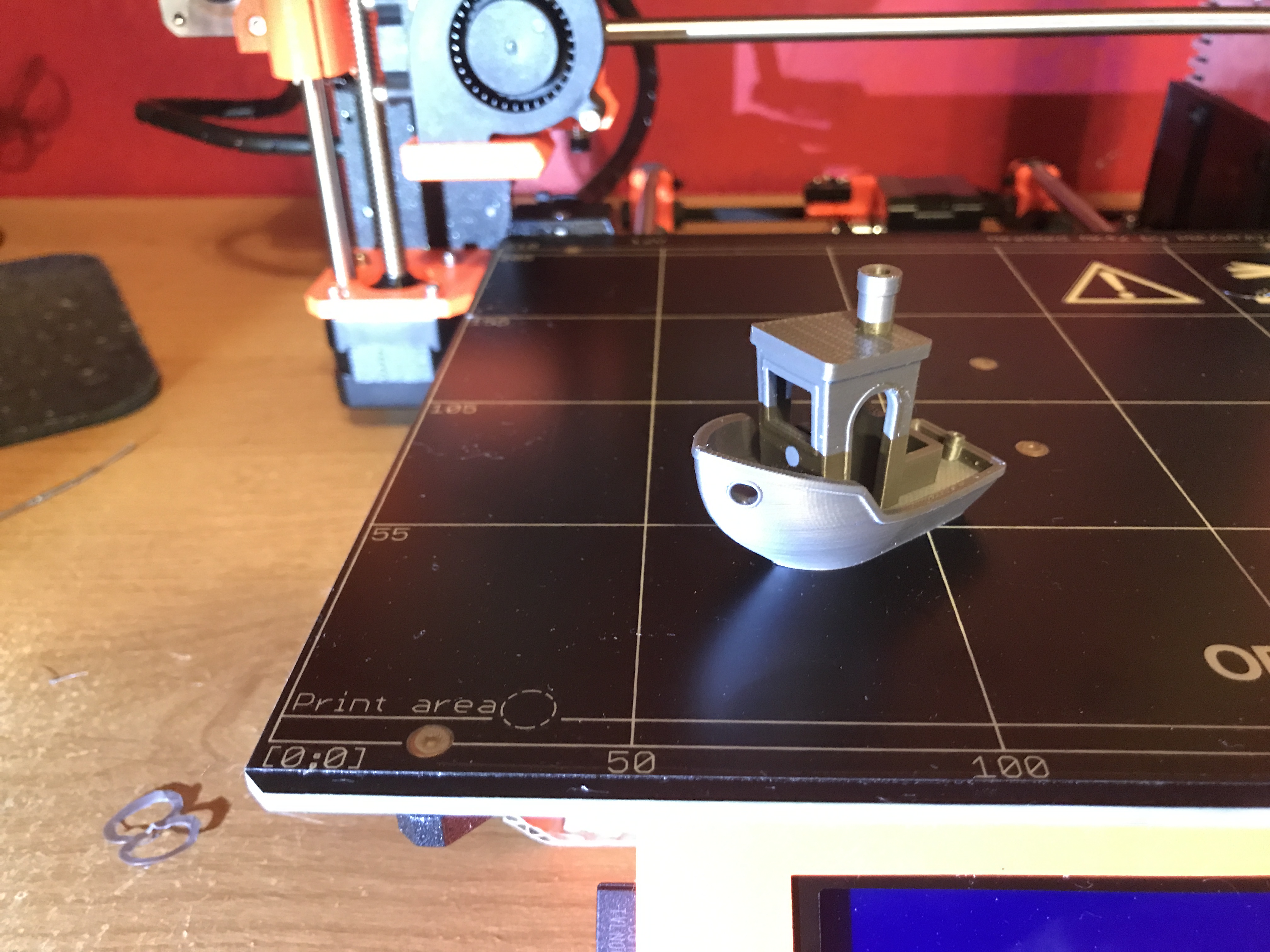

This second image is a print I did in two colors, next to it is the same model printed single color for a constant. It is black and sort of hard to see but the face quality is exactly the same as the color printed one which is easier to make out.

Thanks again for the help!

Re: Problems ejecting filament/inconsistent extrusion

Just a word of caution about the cold pull from my experience, undo the top sensor cover where you feed the filament into the extruder and unscrew the two spring loaded bolts which hold the bondtek gear tensioner or you risk breaking the filament. The first time I did a cold pull I lifted my printer clean off the desk and damaged the extrusion which holds the small PTFE tube in the top. This was with PETG filament.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Problems ejecting filament/inconsistent extrusion

@chocki: if you lifted the printer, you tried pulling way too soon. I only use a few ounces of tension while the extruder is warming up. Materials come up without any lifting what so ever.

@Matthew: Your first image shows a good cold pull (or you waited too long to start pulling). Nice V tip and all. Also shows no dirt in the nozzle (no dark or light spots). It also doesn't have the bulge I'm talking about. Here are some photos of cold pulls. The bulge is that area "above" the nozzle shape, up in the heat break. And, it's been my experience the V6 hot end warms the filament there enough it begins to stretch as you do a cold pull, and you get a thin section between the heat break and the tip, like image 2. These are generic images, not Prusa printers.

The two prints show what looks like considerable under-extrusion, like a plugged nozzle. You may want to try another cold pull: you start pulling as soon as you set the nozzle temp, but not too hard (no printer lifting required); and in a few seconds the filament will come loose.

You also appear to have an MMU. I have no experience with an MMU, so the issue you're facing could be related to it, rather than the Mk3 itself.

Re: Problems ejecting filament/inconsistent extrusion

Here's a cold pull I just did - and I let the nozzle warm a bit too long at 50c so it's really stretched a bit... and I didn't bother to clean the nozzle tip and I didn't get the 0.4mm segment. If I were having a problem, I'd do another cold pull.

Re: Problems ejecting filament/inconsistent extrusion

Just a word of caution about the cold pull from my experience, undo the top sensor cover where you feed the filament into the extruder and unscrew the two spring loaded bolts which hold the bondtek gear tensioner or you risk breaking the filament. The first time I did a cold pull I lifted my printer clean off the desk and damaged the extrusion which holds the small PTFE tube in the top. This was with PETG filament.

Thank you for the tip, I did undo the tension bolts on the side of the head and opened the door to dis-engage the idler gear before doing each pull, I suppose I was lucky as the filament pulled out with little effort each time.

For reference, I kept pressure on the filament towards the extruder until it cooled to just under 100 C and yanked.

@chocki: if you lifted the printer, you tried pulling way too soon. I only use a few ounces of tension while the extruder is warming up. Materials come up without any lifting what so ever.

@Matthew: Your first image shows a good cold pull (or you waited too long to start pulling). Nice V tip and all. Also shows no dirt in the nozzle (no dark or light spots). It also doesn't have the bulge I'm talking about. Here are some photos of cold pulls. The bulge is that area "above" the nozzle shape, up in the heat break. And, it's been my experience the V6 hot end warms the filament there enough it begins to stretch as you do a cold pull, and you get a thin section between the heat break and the tip, like image 2. These are generic images, not Prusa printers.

The two prints show what looks like considerable under-extrusion, like a plugged nozzle. You may want to try another cold pull: you start pulling as soon as you set the nozzle temp, but not too hard (no printer lifting required); and in a few seconds the filament will come loose.

You also appear to have an MMU. I have no experience with an MMU, so the issue you're facing could be related to it, rather than the Mk3 itself.

I'm actually still waiting on my MMU to arrive, I was attempting to do a manual filament change using a Gcode I generated with this:

https://www.prusaprinters.org/color-print/

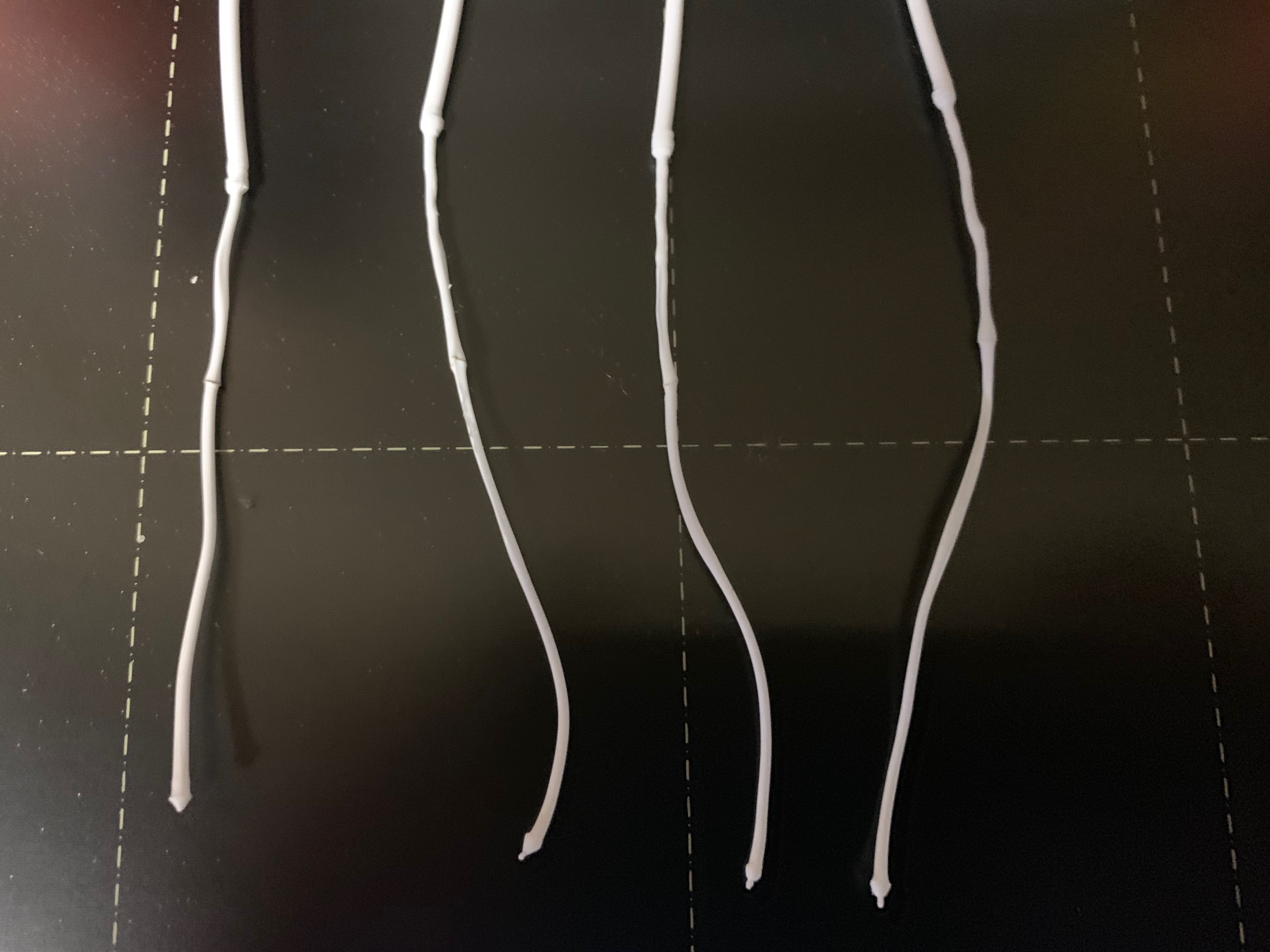

Those images helped a lot to hone in what I was looking for here, I ended up doing 4 cold pulls just in case, they seem to be close to your picture.

I used white filament so that I could see if it was pulling anything weird and I was getting a small amount of black deposit at first, by the 4th pull it was clean. I'll post an image of the pulls as well.

Although that's hardly needed as I'm happy to report that after performing the pulls, I re-printed the model and it came out perfectly, no under-extrusion at all, actually a little stringing even 🙂

As a bonus, I did have a very quiet "Squeaking" from the extruder previously that I chalked up to maybe the filament passing through the gears, however that noise is completely gone now, I believe your advice on adjusting the shaft for the idler gear may have had that effect.

Also, the filament ejected cleanly without getting stuck.

Thank you for taking the time to check out my thread and for helping me to sort this out, you were right on the money from the start.

Just for fun, here's the picture of the pulls, they're in order from left to right. In the first two in the area that I'm assuming is the filament just starting to go into the extruder from the PTFE tubing you can see some black.