Printer not extruding filament anymore

I have a MK3S printer that has been working fine printing PLA until about 3 days ago when I started to notice clicking coming from the extruder during a print.

The issue is that little to no filament is coming out of the nozzle during a print, if any filament comes out it is very thin and is not the correct amount that should be coming out of the nozzle.

I researched more about this issue and found out it was likely due to a clog somewhere in the printer so here is what I tried in order to fix it:

- Heating nozzle to 260 degrees for a few minutes, moving the cleaning needle around in the nozzle to try and break any blockage up

- Doing 3 separate cold pulls, there was a small amount of residue on the first pull but the other two seemed to be very clean. The issue kept happening after these cold pulls were done

- Disassembling the extruder block to check if the PTFE tube was blocked, there was no blockage so I put the tube back in and reassembled the extruder block

- Manually running the extruder from the settings menu to see if the material will exit, this works as expected and does not appear to be blocked when manually dispensing filament

- Trying PETG filament instead of PLA / different roles of PLA, the same issue occurs with the PETG material and other roles of PLA that have worked in the past

- Loosening the screw that holds the gear that moves the filament into the hot end

- Increasing the temperature / flow rate during the print to see if any changes occur, nothing worked

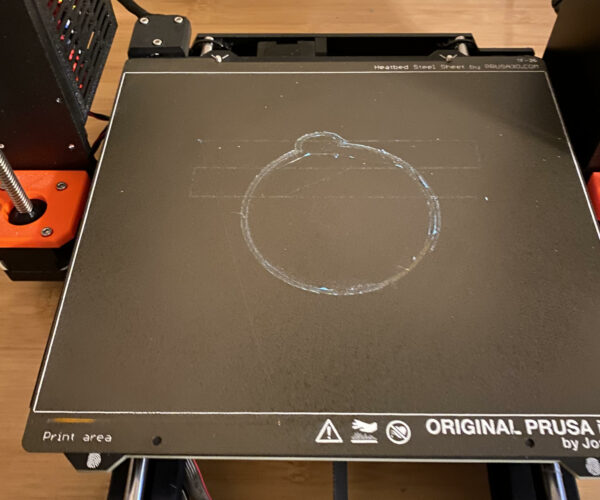

Below is a picture of what the print bed looks like after a few attempted prints, the filament is very rough and thin and does not like to stick to the bed in large amounts.

I was able to get a print to work that started out not outputting the right amount of filament but eventually seemed to correct itself and finish the print with no mistakes. I'm also not getting the clicking noises anymore but the filament still does not exit.

My next step was going to be to remove the nozzle and clean this out, but it seems as if the nozzle is clean judging from how the cold pulls I did looked and that the filament will exit the nozzle correctly when manually activating the extruder from the settings menu. I was also reading that this issue could be cause by a bad heatbreak in the printer and replacing it with a higher quality one can fix the issue.

I'm wondering if anyone has experienced this before or has suggestions I can take to try to resolve this.

Show a picture of the filament tension screw

Let's look at your filament tension screw. You mentioned that you loosened it. Doh. Clicking (symptom) indicates you need to tighten it, not loosen it. Show a picture of your filament tension screw - where it comes out on the right side.

Tried to tighten the filament tension screw

Still no luck, don't hear the clicking sound much more even with the screw tightened (it still happens from time to time) but the filament that is produced is really rough and is not flat on the print bed at all. The amount of filament that was coming from the nozzle was decent after I tightened the screw and tried the same print, but about 5 minutes in the filament stopped coming out pretty much entirely again.

I guess I will try to take the nozzle off completely and clean that to see if there is any blockage

Three more turns

You want the screw portion of that shot to protrude from the nut just a little bit, normally. Also, if you have been running it overly loose, there is a good possibility of filament build-up on your bondtech gears - you might want to fully loosen that screw, open the access door, and see if the little rough part of those gears that grabs the filament needs to be cleaned out (use a small pliers, tweezer, etc). Then refit the screw, and tighten it until it sticks out of the nut by two or three threads.

Found out the issue

Thanks everyone for your replies, I finally found out what the issue was:

For some reason, the Z-axis offset was not correct anymore (I had it set to -1.000) after I ran the Z-axis calibration a few times and adjusted the offset up to -0.650 the prints started coming out fine again. Not sure why this seemed to happen so suddenly, -1.000 offset had always worked well for me up to a certain day and then this adjustment was needed to get the printer working correctly again.

Live Z is not a thing that is static

Get used to watching for that. Live Z will need to be adjusted with any sheet change (such as smooth to textured), and very often if you change material type (petg, pla), brand, or sometimes even the color of the filament. My advice is try not to think of Z as something you can set and forget. Watch each and every print for the first layer going down well - and if it's not adhering (too high) or over-adhering (wavy looking) you have the rest of the layer to save the print.