Re: Playing with the air nozzle design

This is ridiculous, but I can not print the nozzle standing in the way Holger and Stahlfabrik can. At a height of 1.5 to 2 mm, printing stops with "BED PREHEAT ERROR". I have tried five times now and just can not.

I've done the gcode several times, turned the model and changed the settings. I have reinstalled the firmware and restarted the printer, but nothing helps.

There is no hardware failure on the printer, because if I put the model down at the bottom there is no problem printing it!

Does anyone have a good explanation for this?

(I'm still working on version C of the nozzle. It is difficult to distribute the airflow correctly on both sides and to have a nice and smooth inside.)

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

Seems to be a broken cable / loose contact in the wiring harness. Occurs more often. Have fun with the repair. 😉

Greetings Holger

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Re. the "BED PREHEAT ERROR", same problem here occasionally when I choose bed temperatures in excess of 100°C. If you observe the process, you may find that it takes very (and thus eventually too) long for the bed to heat up from 100 (1st layer) to 110 for the followig layers.

It doesn't look like a cable/contact problem to me - I found that, by design, the i3 MK3 doesn't have enough heating power to *reliably* work above 100°C bed temperature, especially at low ambient temperatures and also depending on how much the fan cools the bed surface. I see that Holger uses 95°C., this works perfectly well here too.

(BTW I suggest that, when discussing printing results, it would help to post the full settings data including temperature, cooling, speeds etc.)

Kind regards, thanks to all and keep up the good work!

Hannes.

Re: Playing with the air nozzle design

Hannes, thank you for your infomation! I will have a look at this.

I've tried the bed temp some days ago to max. 115°C without any issues, my printer is powered with 230V.

The cause could therefore be too high electrical resistance in the wiring.

Greetings, Holger

2x Personal MK3IR-BMG09 (Full) BEAR + MMU3 mod., ...

Re: Playing with the air nozzle design

Jaohann, you've probably right, but could it also be a bug in Slic3r?

My printer works to 100% when the model is down, but if I rotate it 45 degrees as Holger does, and I get the error message and the printout is canceled.

So hardware failure in cables or thermistor can be omitted.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

This is ridiculous, but I can not print the nozzle standing in the way Holger and Stahlfabrik can. At a height of 1.5 to 2 mm, printing stops with "BED PREHEAT ERROR". I have tried five times now and just can not.

I've done the gcode several times, turned the model and changed the settings. I have reinstalled the firmware and restarted the printer, but nothing helps.

There is no hardware failure on the printer, because if I put the model down at the bottom there is no problem printing it!

Does anyone have a good explanation for this?

(I'm still working on version C of the nozzle. It is difficult to distribute the airflow correctly on both sides and to have a nice and smooth inside.)

Are you on version 3.5? I get that error there too when printing abs. I downgraded to 3.4.1 and there the error does not happen. I think the reason is the PSU that delivers not enough juice to heat the bed up fast enough. Maybe we have (soon) broken PSUs?

When I heat the bed without printing from 100 to 110C the temperature curve is smooth. When I look at the curve while printing, it is not smooth anymore but gets "steps" - after the first layer the motors go faster and need more amps. Then the fan kicks in and takes it share of power. Something must be different in the firmware 3.5.0 regarding the error. I bet it is underpowered PSU.

There is a GitHub issue, RHDreambox that you can happily contribute too:-)

Re: Playing with the air nozzle design

Just for the record... finished a nozzle duplicating Holgers slanted setup as closely as I could (including a bed temp. of 95°C), looks reasonably good to me. His nozzle temperature of 230°C seems to be a bit on the cold side for the Prusa ABS I'm using, so I should try again with my usual 250°C eventually.

Re: Playing with the air nozzle design

for those getting "BED PREHEAT ERROR", i suspect nozzle fan cooling the bed not help to reach the target temperature in time. particularly if there is high speed fan when bridging on top of supports.

you could print far from where the bed thermistor is under the bed.

or set the first layer temp to 110° too.

or warm up your enclosure if you have one.

that is just suppositions.

Re: Playing with the air nozzle design

When printing abs at 255C the nozzle printed in abs melts on the left. This is also a problem with the stock nozzle but I think the problem is not as pronounced there for whatever reason.

Anyway what material should i print this in to have no more that problem? What could you recommend?

Re: Playing with the air nozzle design

I print my one in polycarbonate and I got no problems with a deformed fanduct any more. Even with 275 / 110 without cooling on.

I buy a super cheap sample from Amazon and used the polycarbonate profile from georg.s2

Re: Playing with the air nozzle design

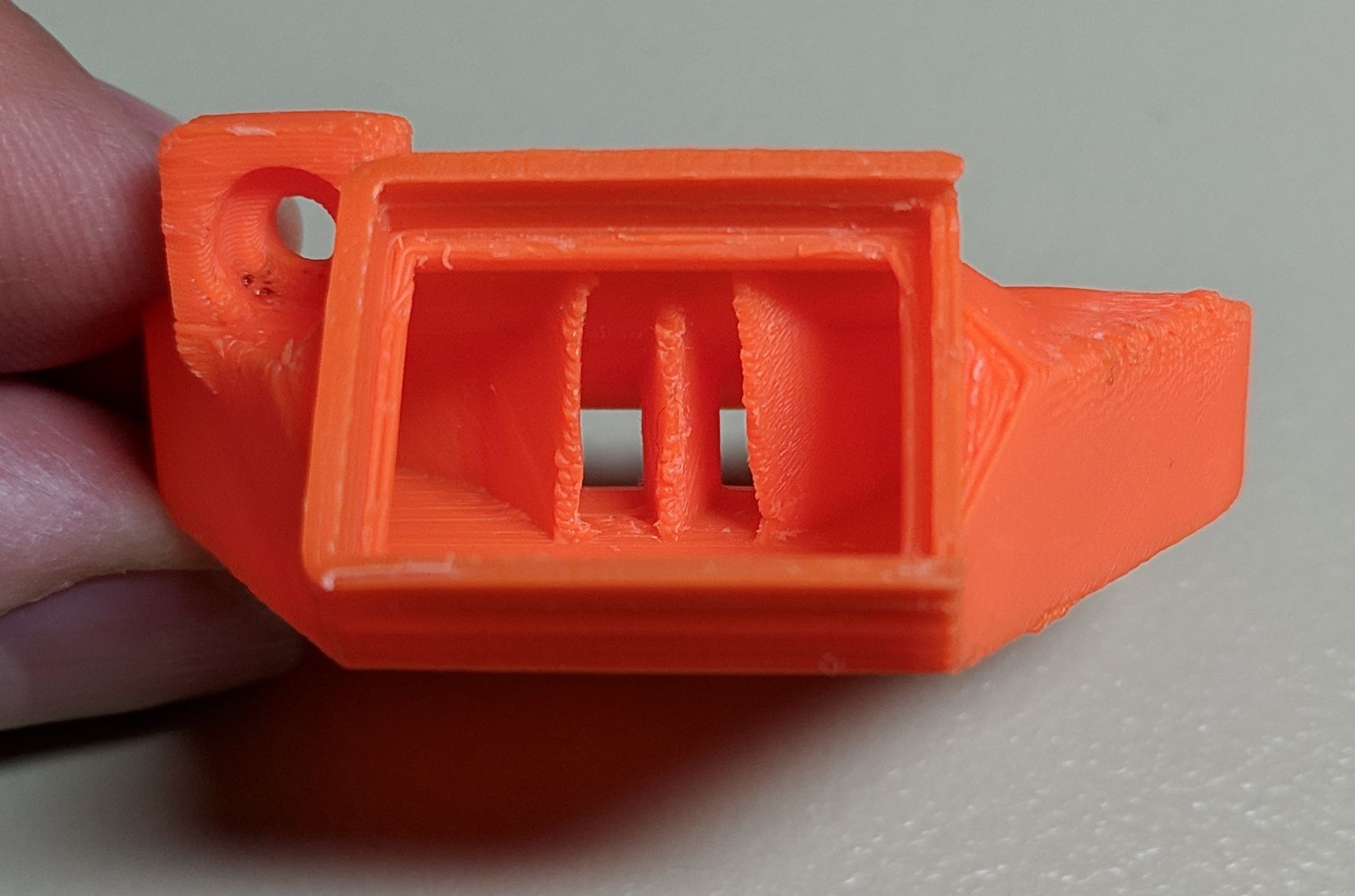

Nozzle RHD Revision C is now uploaded at Thingiverse

https://www.thingiverse.com/thing:3249344

The deformation of the tip of the nozzle left side is a little strange. Could it be due to heat radiation from the thermal cartridge cable end, or is the extruder fan that sucks warm air over the tip from the hotend?

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

Nozzle RHD Revision C is now uploaded at Thingiverse

https://www.thingiverse.com/thing:3249344

The deformation of the tip of the nozzle left side is a little strange. Could it be due to heat radiation from the thermal cartridge cable end, or is the extruder fan that sucks warm air over the tip from the hotend?

Is this a legit competition by Prusa? If so you should apply: https://www.myminifactory.com/competition/pimp-my-original-prusa-160?fbclid=IwAR2uQE3CPYkN0bB4xVT6r_pvXnltK3go0WucQIE_8Tx6HQPNmzGnv5abj9g

Re: Playing with the air nozzle design

Hi Stahlfabrik,

I did not know about this competition, so why not?

I think in fact that the nozzle has a low level of competition, but it may be a fun thing to participate.

I'll see if I can get some interesting information to join.

Thanks for the tip 😀

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

I just printed the rev C flat and on 135 degree. The flat version came out great! No more sagging strands. Much improved design!

The 135 degree versions inner fins came out quite molten - I guess I would need to increase fan or lower temp.

But since the flat version came out so nice - I really wonder if the 135degree way of printing is still so relevant for me.

So now lets test it:-)

Re: Playing with the air nozzle design

It was nice that the nozzle that you printed out was good.

It was a bit difficult to avoid internal strings and uneven surfaces. But with the help of some small internal radius in suitable places, it worked much better. Please tell us about your tests and if there is any point you think we can improve.

I might think about a whole new model during Christmas.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

So I printed my test peace again.

Sadly I was stupid and had thrown my old gcode away AND I had to open a new spool of the same filament. Still I hope I was able to recreate a fair comparison.

The rev C nozzle DOES perform better than REV B. The right side overhang was now 59 degrees - up from 57 degrees. And in the back it is hard to tell but I think it is also improved there. So GOOD JOB!

Also I like that the outlet walls are now thicker. Also - as you have mentioned the overhangs came out great!

I just received an sample of Polymake PC Max. I hope I get it dialed in quickly as I only have 50g. But Prusa Slic3r has a setting for it so fingers crossed!

Re: Playing with the air nozzle design

So I printed the nozzle in Polymaker PC MAX

My settings: based off of 0.15 standard Prusa setting: Limit printing speeds by min 30mm/s and max 50 mm/s. Increase Live Z by 0.040 mm. Use Prusa PC Max profile, but change nozzle temp to 260C and bed to 110C after the first layer. Retractions were not perfect yet /stringing. I used 1.5mm at 45 mm/s. Z-lift 0.0mm. Enable fan and auto-cooling (min speed 30mm/s). Use glue stick on the PEI sheet.

The outcome is quite beautiful. Carefully removed strings with heatgun (first time I melted the inner fins:-()

Re: Playing with the air nozzle design

Tried similar settings (but nozzle = 270°C) yesterday, flat, with ICE PC Pro... very good details and surface, no stringing, and slight warping (both front ends pulled off the bed a little bit) but alas delamination at about 1/3 of Z max and again at the mounting tab. ICE PC seems to require *much* higher temp than Polymaker PC-MAX... will try again tonight with 285°C but I fear that warping will get worse then.

Re: Playing with the air nozzle design

Tried similar settings (but nozzle = 270°C) yesterday, flat, with ICE PC Pro... very good details and surface, no stringing, and slight warping (both front ends pulled off the bed a little bit) but alas delamination at about 1/3 of Z max and again at the mounting tab. ICE PC seems to require *much* higher temp than Polymaker PC-MAX... will try again tonight with 285°C but I fear that warping will get worse then.

You could try the settings I posted in the Polycarbonate thread. I used them for Hobbyking PC and that is also quite difficult to print.

https://shop.prusa3d.com/forum/print-tips-archive--f86/polycarbonate-here-s-how-to-print-it-without-warpi-t6919-s60.html#p117891

Re: Playing with the air nozzle design

You could try the settings I posted in the Polycarbonate thread. I used them for Hobbyking PC and that is also quite difficult to print.

https://shop.prusa3d.com/forum/print-tips-archive--f86/polycarbonate-here-s-how-to-print-it-without-warpi-t6919-s60.html#p117891

Do you have an enclosure ? I tried printing the nozzle with the same settings you posted and getting very frequent delamination with the same HK PC.