PLA ooze and print problems changing nozzle

I have been printing with a 0.6mm nozzle on my MK3S without an issue. I changed back to my 0.4mm for better resolution, but now I cannot get the 1st layer to calibrate correctly. PLA isn't sticking well and curling at the edges on the 1st calibration. The nozzle is also oozing all the time, which seems to be catching and pulling prints off the PEI sheet.

The other thing I noticed is that when it does a calibration before printing, little dots of PLA are left behind on the PEI sheet. I guess this is also from the oozing. I don't remember this before I switched to the 0.6 mm and certainly didn't have it while using the 0.6mm. Any advice to get the 0.4mm working again? Z-height calibration looks right using the 1st later cal (lines are together, not too squished or spread out). If I try to print, I usually end up with a PLA blob on the hotend or a spaghetti monster. Everything has failed and need help please! I am using the standard Prusa profile for printing.

RE: PLA ooze and print problems changing nozzle

I am having a similar issue but with filaments. I had Z-height zeroed in for PLA then changed to use PETG, adjusted the settings using the slicer rather then change the Z-height, but when I go back to print with PLA the first layer doesn’t stick anymore.

Michael S.

RE: PLA ooze and print problems changing nozzle

If you change from filament, like pla to petg, clean bed with dish soap, so no filaments stays on bed, and 2 filaments mixing is not good.

The sticking problem is:

Most important for 3d printing is:

1. Clean bed, clean with dish soap, dry it, and print, no alcohol needed.

2. First layer needs to be 100% perfect.

1 and 2 are needed for sticking to bed, and so you do not have a big ball of filament sticking to nozzle, and if first layer is not good higher up in print you could also have problems.

General how I work:

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wen model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%, and bed not clean.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked, or partial blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.

If you see white spots like a bubble on the bed, then filament is releasing from bed.

Also no gabs between lines should be visible.

Use 7x7 calibration for first layer, see settings in the printer.

Search for " 3D printer first layer problem Calibration process" on youtube, movie on first layer calibration, with a good zoom in.

RE: PLA ooze and print problems changing nozzle

@peter-m26

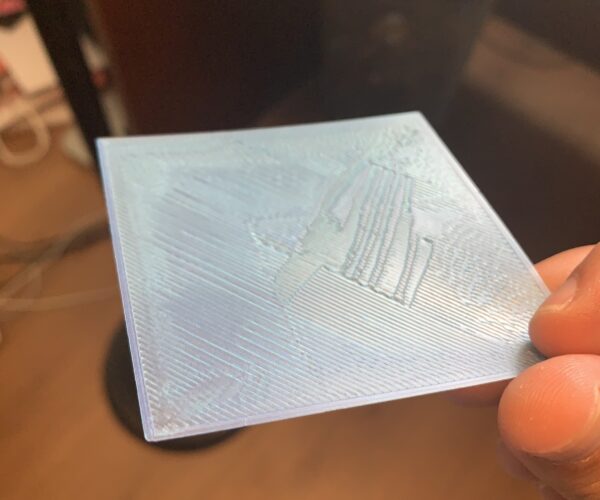

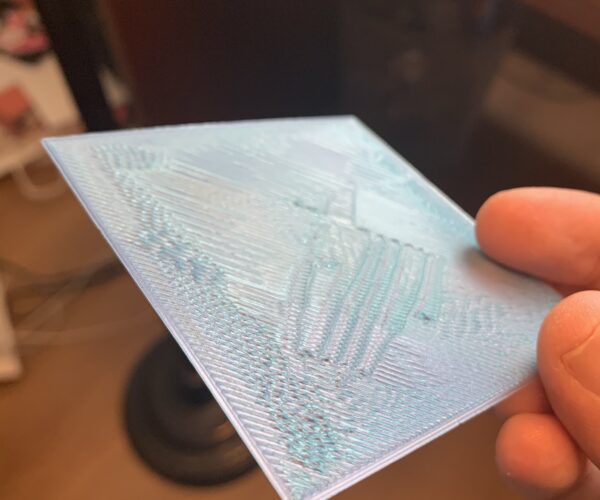

Thanks Peter, I used Dawn to clean up bed, cold pull using PLA, spent a long time watching views, and trying to calibrate the first layer. I have made a lot of head way with my first layer squares from( https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/) the bottom is smooth and there are now gaps (first image) but the top layer is all rough(second image).

I thought this would be fine since the bottom was smooth and everything stuck together but when I try to print a full model the nozzle starts to catch bits and soon filament is falling into a ball around the nozzle. Am I doing something wrong? Also, I mean t0 highjack a thread, this is my first printer.

Thanks,

Michael S.

Michael S.

RE: PLA ooze and print problems changing nozzle

[...] I thought this would be fine since the bottom was smooth and everything stuck together but when I try to print a full model the nozzle starts to catch bits and soon filament is falling into a ball around the nozzle. Am I doing something wrong? Also, I mean t0 highjack a thread, this is my first printer.

Your Live-Z is still a bit too low (too negative). Try bringing it back up (less negative) by 0.06 or so. Bring it up in 0.02mm increments until you notice small gaps between the extrusions, then lower it an increment or two. You should get smooth top surfaces, but the sheet should not tear easily when removed after printing. More notes here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA ooze and print problems changing nozzle

Example how to do a first layer calibration.

You have to do this every print, check the first print line and adjust if needed, then wen the whole first layer is ready check again, to see if the layer is correct.

RE: PLA ooze and print problems changing nozzle

@peter-m26

Thanks for this additional first print info. Unfortunately, it hasn’t solved the issue of calibration dot ooze. I also still have curling on edges, so while adhesion is good, the curling is causing prints to catch and stick to the nozzle. This pulls them off the sheet or generates spaghetti.

Any other ideas?

RE: PLA ooze and print problems changing nozzle

@nealabrams

Do you have a video of the filament curling?

Michael S.

RE: PLA ooze and print problems changing nozzle

Clean bed with dish soap.

RE: PLA ooze and print problems changing nozzle

I created a video showing the "ooze dots" with calibration. You can also see the curl at the end of the initial line before moving to the skirt.

RE: PLA ooze and print problems changing nozzle

I created a video showing the "ooze dots" with calibration. You can also see the curl at the end of the initial line before moving to the skirt.

You're experiencing 2 different issues. Don't mix them together for troubleshooting:

The lifting is an adhesion issue. This can be a combination of Live-Z calibration and bed cleaning.

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some tribes deep in the jungle have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

The dots are a filament oozing issue. On start up, the nozzle and bed are heated at the same time. The bed warms much more slowly, so filament will sit in the nozzle at printing temps for several minutes in some cases. Different filaments will start oozing at different temps. Your choices are:

- Heat both nozzle and bed to print temps at same time (default).

- Heat bed to print temp first, then heat nozzle (slow).

- Use 2-step nozzle warmup.

The 2 step nozzle warmup is roughly:

- Start heating nozzle to no-ooze temp (I use 160C).

- Start heating bed to final print temp (e.g. 65C).

- Wait for nozzle to hit no-ooze temp (you want filament soft to avoid dangling bits damaging the PEI).

- Wait for bed to heat to final print temp.

- Home.

- Do mesh bed calibration.

- Set nozzle tempt to final (oozing) temperature after bed leveling completes.

- Start print.

All of this is done in startup gcode (Printer Settings->Custom G-code->Star G-code). You can do a lot of other things pre-print such as waiting for a consistent PINDA/MINDA warmup temperature before mesh bed leveling. I have a documented example here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA ooze and print problems changing nozzle

@bobstro

I have to say, things are much better. I had already done the "Life Adjust" process, but editing the start gcode seems to have made a big difference.

- No more dots on calibration and oozing is much less.

- The prime line is stringing beforehand, but not afterwards, so that is a major improvement.

- I lowered the bed temp back to 60C (from 80C), still works well.

For adhesion, I did a wash with Dawn too, but was using 71% IPA before, not 90%. As you said, two issues and I should not combine them. I hadn't thought of that. I switched from 0.4mm to 0.6mm nozzles and didn't have much trouble, but going back to the 0.4mm has been a bear. Prints still aren't perfect, but better. I'll keep tweaking the g-code for oozing, but adhesion seems much improved. Thank you!

RE: PLA ooze and print problems changing nozzle

[...]

- I lowered the bed temp back to 60C (from 80C), still works well.

Just a quick clarification: If you're referring to the initial 80C bed temp in my sample startup gcode, that's to speed up the PINDA warming process. The bed temp drops to the temp specified for the filament as mesh bed leveling completes. I find it's usually at 65-70C when the prime line prints. Nothing wrong with it being lower, but if you like the PINDA & bed warming, good to be aware of it.

Glad you got the worst of it under control!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA ooze and print problems changing nozzle

Thanks @peter-m26 and @bobstro, I was able to zero in calibrating the Z and the prints are a lot better! You guys rock.

Michael S.