Pinda hardware testing inconsistent at any given temperature

Hello.

I ordered another Pinda probe with the intention of installing and calibrating to try and get my first layer height consistent between prints at varying temperatures.

Before I installed it (I still haven't) I spent some time testing in as accurately as I can and I can't seem to get a consistent reading at any given temperature. That is any given temperature the inbuilt thermistor reports to me.

At fist power up the triggering distance changes widely for a few seconds.

Triggering distance can change 10's of um at the same temperature depending if it has been cooling or heating.

My test rig currently drives the pinda up to the side of a stepper motor so perhaps this is an issue. But to save me some time, if someone knows weather this is normal or not let me know.

Thanks.

Re: Pinda hardware testing inconsistent at any given temperature

The stepper motor probably has varying magnetic fields during operAtion

Which could throw the results Off

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Pinda hardware testing inconsistent at any given temperature

The angle change per step of the motor shouldn't change as a function of temperature. The torque will decline as the steel and the magnets get hot, but short of skipping steps (e.g., due to stalling or binding) it won't make a difference. You're probably seeing the repeatability error of the sensors and their measurements.

Re: Pinda hardware testing inconsistent at any given temperature

Thanks sasha.

I think Joan was saying the same thing, only that the error might be todo with the probe picking up the changing magnetic feild around the motor. I've made a little stand off and do the test again anyway.

Re: Pinda hardware testing inconsistent at any given temperature

that was my point!.

on the prusa the pinda is separated from the motors by a short distance

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Pinda hardware testing inconsistent at any given temperature

I have tested again running for over 24 hours and I get s similar result.

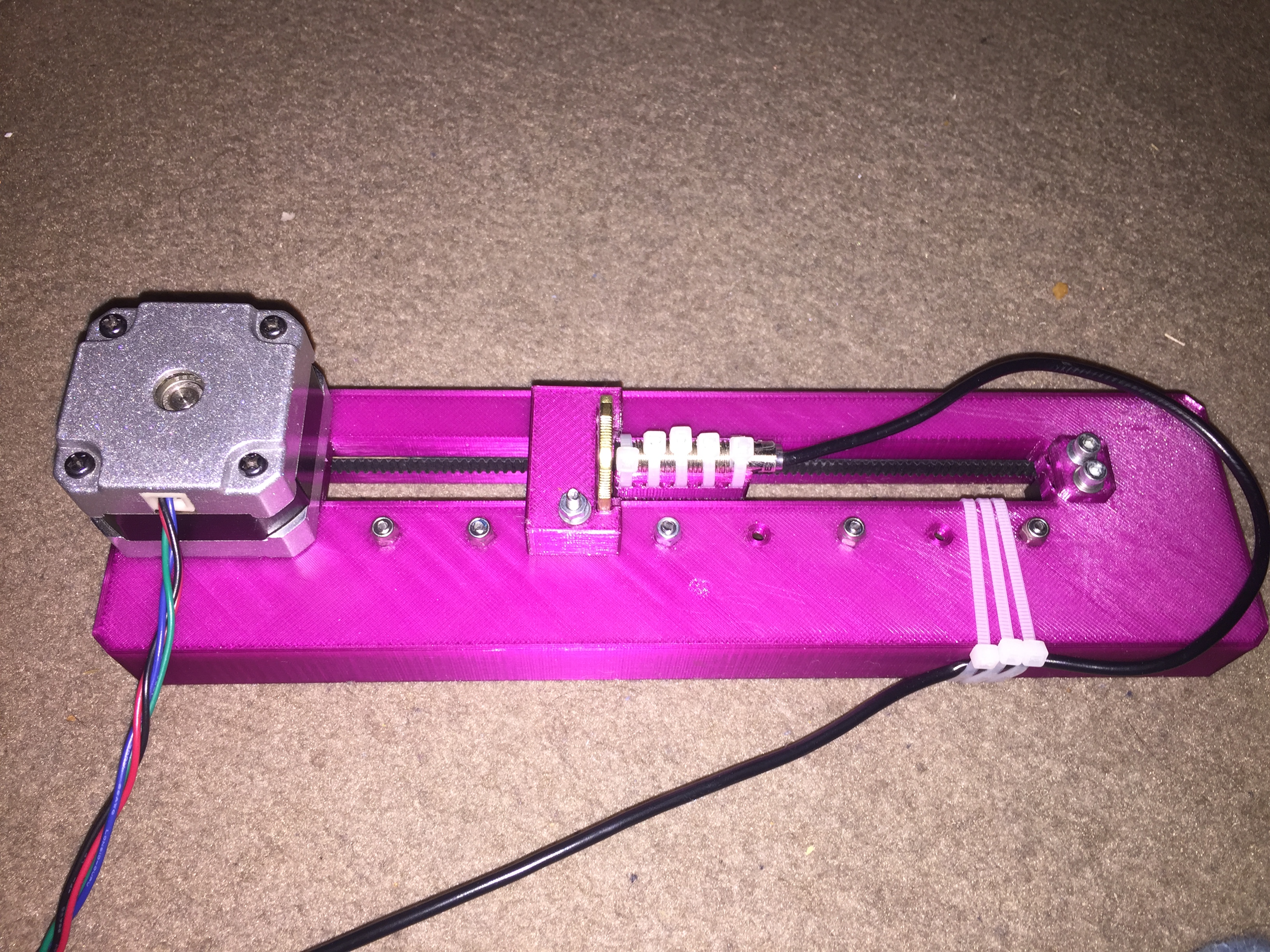

Here is the test rig now:

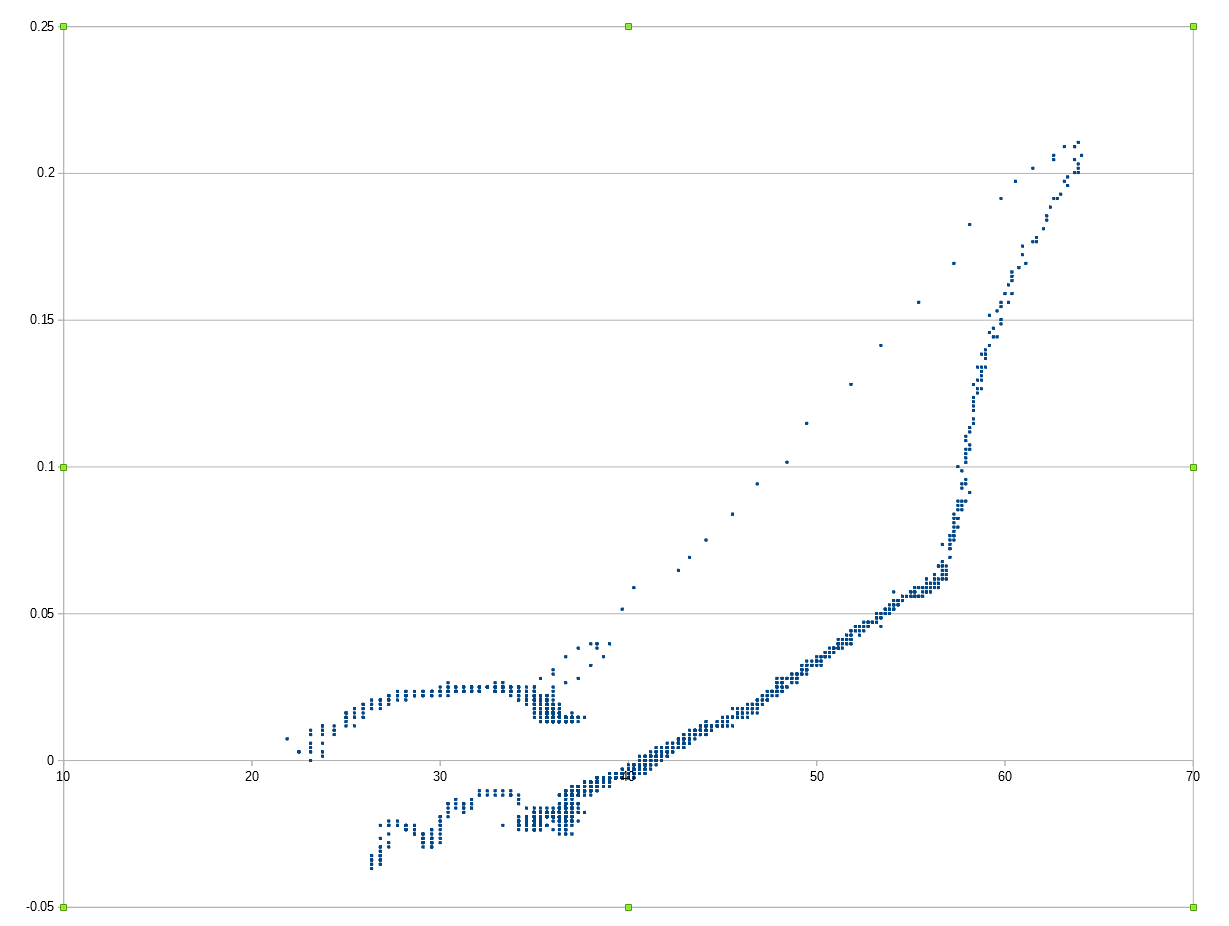

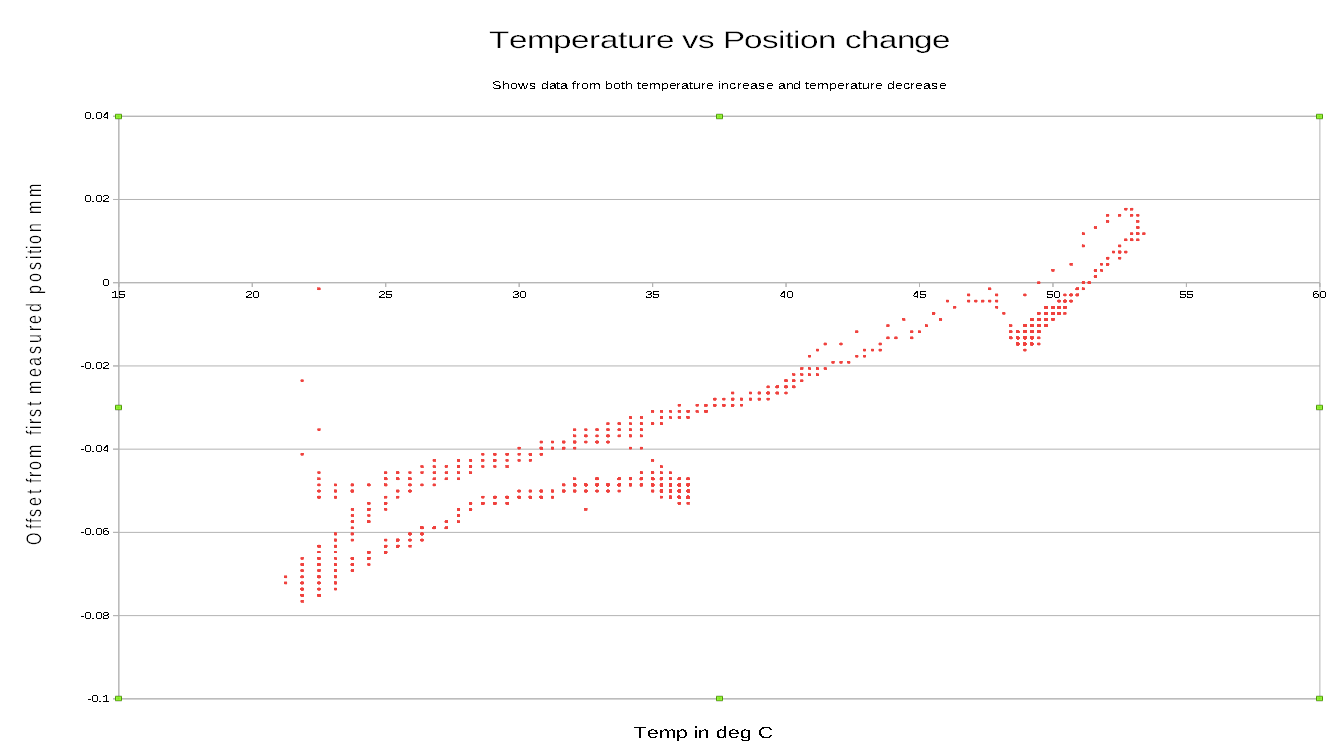

This is the results:

I'll attach the data.

If anyone else tests these and gets a different result let me know.

Thanks.

Note low res ADC on nano. 128 microstepping on motor/rail setup from an old up mini i think it was.

10 seconds between samples.

temp/microsteps/mm conversion.

20.00,1,0.0014726215mm

20.62,1,0.0014726215mm

20.62,2,0.0029452430mm

20.62,1,0.0014726215mm

20.62,2,0.0029452430mm

20.00,2,0.0029452430mm

20.62,3,0.0044178647mm

20.62,3,0.0044178647mm

20.00,4,0.0058904862mm

edit.. 60,000 char limit.

Edit: Despite starting at room temp 23.75C, heating up and cooling down , and remaining at 23.75C for some hours the probe still triggers at some 10um different that when the testing started 23h earlier.

Re: Pinda hardware testing inconsistent at any given temperature

Hi Mk3Gibbs

I am interested in your tests... they could help us all.

I believe the Pinda is an NPN open collector switching device so I am wondering why you are using a analogue to digital port to test it's output?

surely you should be using a digital port with a pull up resistor? that would remove the potential of analogue to digital conversion timing, affecting the results

is Belt drive a reasonable comparison to leadscrew drive ? I think there are something like 4 times as many steps per milimeter for leadscrew drive, compared to belt drive... would this not make leadscrew drive more likely to give repeatable results?

is there any chance of adding an opto switch as a second sensor as a 'tell tale'.... if the opto sensor is rock steady reporting exactly the same position whilst the pinda is wavering, then you have a Pinda issue to look for, if the opto switch also wavers in reported switching position, then your rig is questionable

your pinda sensing distance is about 2mm so if you set the opto sensor to trigger say 1/2 mm after the expected pinda trigger point, , you could advance the rig, sensing for the pinda to trigger in one sub routine, then switch to check the opto in another subroutine so that the timing of each sensor is not affected by looking for the other sensor, but both sense points are close together with the carriage travelling in the same direction for each measured sense point

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Pinda hardware testing inconsistent at any given temperature

I agree wrt/ADC for measurement - you should be using a digital input and using an interrupt to capture the position immediately.

The best source of truth would be an electrical contact closure, also being captured by an interrupt.

Re: Pinda hardware testing inconsistent at any given temperature

Hello again.

I am using the ADC on an arduino nano to do the thermistor reading just like on our prusa's. (I'm using their tables modified for 8 bit ADC on arduino nano)

I'm using the stepper motor + driver + linear rail out of a little up mini that is hardware setup for 128 microstepping which they must think they can acheive. With the 12mm pulley its 680 steps/mm.

Initially I did build a lead screw but positioning didn't look anywhere near as accurate.

The code works by moving the pinda away from the metal, then driving it in 1 step, measuruing tempreature, checking if the position has been made, and repeating until the pinda switch is made.

The graph shows the change in position that the pinda probe registers relative to the starting position that was registered on startup at room temperature. So as expected the position where the proximity switch registers varies with temperature but it isn't consistent.