Nozzles...

Getting ready to order some nozzles. We plan on (eventually) printing a variety of materials--some likely abrasive--some not. Would it make sense to just order hardened steel in a variety of sizes (apertures), or is there some reason hardened nozzles shouldn't be used for everything all the time?

That's "MISTER Old Fart" to you!

Re: Nozzles...

Hardened steel doesn't conduct heat as well as brass or copper, so the conventional wisdom is to use one of those materials for general-purpose printing and reserve hardened steel for where it's needed. That said, I have started using hardened steel nozzles for all nozzles greater than 0.40mm which I might want to use for filled filaments. I haven't encountered any issues with hardened 0.40mm and 0.60mm nozzles for everyday use.

Getting ready to order some nozzles. We plan on (eventually) printing a variety of materials--some likely abrasive--some not. Would it make sense to just order hardened steel in a variety of sizes (apertures), or is there some reason hardened nozzles shouldn't be used for everything all the time?

For smaller sizes, I'm not going to risk clogs so I won't be using these sizes for filled materials. I go with plain brass. I did order a 0.25mm plated copper nozzle, but only because the supplier was out of the plain brass version at the time. Plated nozzles are supposed to adhere less to PETG and "sticky" materials, but I'm only using it with PLA and haven't noticed a big difference. I'd go with something cheaper than hardened steel for smaller sizes simply for economy.

The cheap knock-off nozzles work OK for PLA if you want to experiment with sizes. I've read of them not working so well with higher-temp materials. I could never print with a 0.20mm cheap brass nozzle. I am not sure a genuine E3D nozzle would print better at that size, much less their new 0.15mm size.

Be sure to get a 16mm wrench for the heater block and 7mm socket for the nozzles. They make changing nozzles much easier. Dropping a hot nozzle when using pliers is no fun at all, and having one bounce up under the printer and stick to a magnet is really annoying!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Nozzles...

some say the Hardened steel don't transfer heat a well as the brass,

others say the brass are cheap enough to use and lose... simply change when they get worn, others swear by the Olhsson Ruby nozzle, others swear at it...

TBH I have never used a hardened nozzle, I have some stainless nozzles, but still have to use one.

you can have loads of fun without going overboard. I have actually just got an assortment of nozzles so I may be playing soon

I have to admit I bought cheap nozzles to literally play with... so I will probably get some earache from my peers on here for being a cheapskate... one thing I will suggest... sort out a holder for your nozzles, early on... they are quite small, easy to lose, difficult to read once used and difficult to tell apart...[attachment=2]20180807_191204[1].jpg[/attachment]

In the picture above you can see the block I made recently...

I bought a set of assorted nozzles, and put them somewhere safe. (Lost)

I had some 0.3 nozzles that I put away safe previously.... Erm.... Misplaced...

so I bought some stainless nozzles, and whilst I was waiting for them to be delivered by Sampan... the other turned up...

and that's what largely defined the size of the nozzle block...

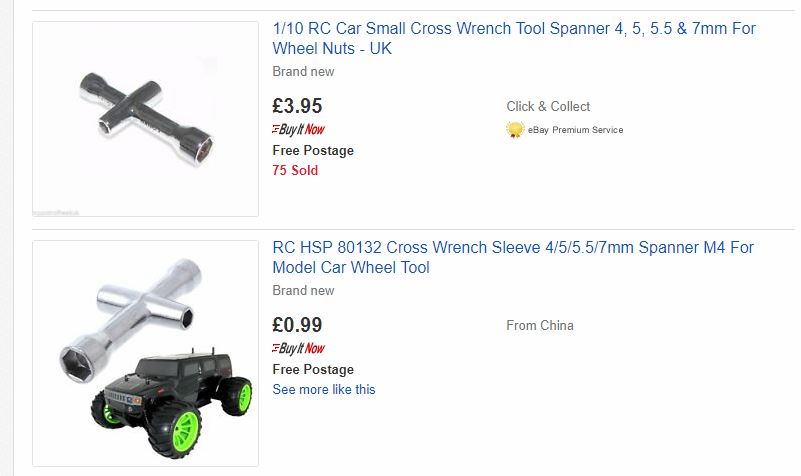

at the back of nozzleblock I have a model car spanner, this is useful because the wings are small enough to stop you overtightening the nozzles when re installing them.

I like the socket in preference to a flat spanner, because :

A, the hot nozzle doesn't drop out onto your build plate,

B, it's a lot easier to align the nozzle with the hole in the heat block without burning your fingers when re inserting the nozzle

c, it doesn't keep slipping off the nozzle in use...

[attachment=0]20180807_191639[1].jpg[/attachment]

also in the picture are copper slip, which I use to stop the screw thread getting stiff inside the heatblock and to the ledt is a number of taps that I picked up on ebay for threading holes. I like them because

1, they were inexpensive

2, they have a tapping size drill integrated

3, they have a Hex head instead of a square head, so I can run them into plastic, with my electric screwdriver...

these are good for 3D printing because you can for example insert a 5mm hole in a model, for a 6mm screw,

then the drill bit section will align the tap with the hole whilst trimming the hole to size, and the tap will follow straight in... Magic...[attachment=1]20180807_193706[1].jpg[/attachment]

above is a tool I made to check the bullet seating depth for my Ammunition. the Black ribbed knob is tapped and countersunk, to recess the screw thread, and a drop or two of superglue ensures that it does not unscrew, the screw is used to trap the black Carbon fibre rod, so that I can measure the cartridge overall length after measuring the chamber

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzles...

As always, you 2 have given me much food for thought, and it's appreciated!

Hardened steel doesn't conduct heat as well as brass or copper, so the conventional wisdom is to use one of those materials for general-purpose printing and reserve hardened steel for where it's needed. That said, I have started using hardened steel nozzles for all nozzles greater than 0.40mm which I might want to use for filled filaments. I haven't encountered any issues with hardened 0.40mm and 0.60mm nozzles for everyday use.

For smaller sizes, I'm not going to risk clogs so I won't be using these sizes for filled materials. I go with plain brass.

That makes sense to me. If you've said that before, that's probably where I got the notion. I think I'll stick with brass for 0.4mm and smaller (haven't quite decided yet if that'll be 0.2 or 0.25) for detail stuff, and go for hardened in 0.4mm and larger (one of each @ 0.4mm).

As my primary interest is in board game components, some will be large enough, or numerous enough, or both--to justify hardened nozzles for filled materials.

Plated nozzles are supposed to adhere less to PETG and "sticky" materials, but I'm only using it with PLA and haven't noticed a big difference.

I did not know that (or if I did, I forgot). I wasn't thinking of plated, but PETG is in the cards for printing replacement parts, so...

Be sure to get a 16mm wrench for the heater block and 7mm socket for the nozzles. They make changing nozzles much easier.

I just put all those on my shopping list (never had call for metric anything before this venture... ) :geek:

some say the Hardened steel don't transfer heat a well as the brass,

others say the brass are cheap enough to use and lose... simply change when they get worn, others swear by the Olhsson Ruby nozzle, others swear at it...

I was mulling getting a ruby nozzle for everything until I realized I'd need several for different orifice sizes. I can justify/rationalize one, but not 3 or 4... 😮

I have to admit I bought cheap nozzles to literally play with... so I will probably get some earache from my peers on here for being a cheapskate...

IME, cheap usually winds up being more expensive in the long run (hence I sprung for the Prusa rather than one of the clones/knock-offs,) but please don't read any judgment into that; there is none.

one thing I will suggest... sort out a holder for your nozzles, early on... they are quite small, easy to lose, difficult to read once used and difficult to tell apart...

That's an excellent suggestion. We have a few spare plastic organizers around; I used a couple to sort all the parts out while building the kit. (I know... I won't drop any hot nozzles in one! 😉 )

at the back of nozzleblock I have a model car spanner, this is useful because the wings are small enough to stop you overtightening the nozzles when re installing them.

Another inspiration! I'll see if I can root one out.

these [taps] are good for 3D printing because you can for example insert a 5mm hole in a model, for a 6mm screw,

then the drill bit section will align the tap with the hole whilst trimming the hole to size, and the tap will follow straight in... Magic...

I think I'd have drilled pilot holes & used self-tapping screws, but whatever works...!

That's "MISTER Old Fart" to you!

Re: Nozzles...

I was looking at the Prusa spares page at Filastruder, in response to another thread, and noticed that they now sell an identical spanner

so I looked at the E3D Page to see if it was available there

and I looked where I got mine from

Please be aware, there is a Black variant of this spanner... It's Plastic... may not work too well with hot nozzles...

p.s. if you choose to use Copperslip or similar on your nozzles, use a piece of paper or similar to catch the first waste plastic after changing the nozzle... you don't want to lube your build plate...

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nozzles...

OK, zeroing in now...

Plated nozzles are supposed to adhere less to PETG and "sticky" materials, ....

Any recommendations/experience (from anyone) what kind of of plated nozzle for PETG? (E.g. Nickle, Chrome, SS... and over what base--brass, copper, hardened steel?)

I'm also planning on ordering some silicone socks. I just heard/read that one of their purposes is to keep the nozzle clean when using PETG/sticky materials. Would that make a plated nozzle redundant? Any reasons to/not to use both (sock & plated)?

I was trying to decide between 0.20 & 0.25, but since they'll be brass (and fairly inexpensive) I guess I may get one of each and see what happens... 🙄

That's "MISTER Old Fart" to you!

Re: Nozzles...

[...] Any recommendations/experience (from anyone) what kind of of plated nozzle for PETG? (E.g. Nickle, Chrome, SS... and over what base--brass, copper, hardened steel?)

My recommendation would be manufacturer 1st, then material based on what they offer. I've been very happy with E3D's "genuine" parts. They only offer hardened steel, plain brass, nickel-plated copper and stainless steel. Stainless is really meant for producing parts with food contact. The nickel-plated copper are supposed to have better heat-transmission properties, and the coating is meant to reduce filament adhesion, so these best fit your description. In reality, I haven't noticed much of a difference between nickel-plated and plain brass. If I were using a nickel-coated heat block and concerned about high-heat materials, the plated might be worth it. I'm using hardened steel for larger (>= 0.40mm) nozzles so I can switch between normal and filled materials without a nozzle swap. I'm not having any problems using hardened steel for everyday printing.

[...] I'm also planning on ordering some silicone socks. I just heard/read that one of their purposes is to keep the nozzle clean when using PETG/sticky materials. Would that make a plated nozzle redundant? Any reasons to/not to use both (sock & plated)?

Jury is still out. Avoid the "pro" socks that fully cover the nozzle. They have a bad tendency to cause more problems than they fix. The more open newer version leaves the tip of the nozzle exposed. I've read plenty of horror stories about socks contributing to making a filament monster worse, so am avoiding them. I get good-enough results by giving the heat block a good rub with a wire brush now and then. There are some threads on these forums you can search for more detail.

I was trying to decide between 0.20 & 0.25, but since they'll be brass (and fairly inexpensive) I guess I may get one of each and see what happens... 🙄

I had no luck with 0.20mm generic brass nozzles. E3D may be better. 0.25mm seems to be an "officially supported" Prusa size. I've had very good luck with the 0.25mm nozzle. Detailed prints look very good. However, print times are greatly increased as you get smaller. Keep that in mind as you go lower in size. Consider how small your smallest detail is (the printer can't print < nozzle size well) and get as large as you can. After some testing, I think 0.25mm is about perfect for my smallest levels of detail (bolts on 1:100 models). As you say, the nozzles are cheap enough that buying extras won't hurt. Make sure you have plenty of time if you try E3D's 0.15mm size.

If you're doing functional parts, be sure to try 0.60mm. It's a great balance between size and finish. Prints can go much faster with fewer perimeters.

I like the Prusa analogy on nozzles: Printing without trying different nozzles is like buying an expensive DSLR camera and never changing lenses. It works, but you miss out on a lot. Have fun experimenting. Just don't get them mixed up!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Nozzles...

I stumbled on an alternate supplier of E3D V6-compatible nozzles whilst reading a thread on Volcano hotend options. They offer brass, aluminum and hardened steel versions, all with a plating that is advertised as improving heat conductivity and reducing wear. They're a bit more than genuine E3D nozzles, but do look interesting. I may order one as an experiment. I found them at Filaments.ca and Push Plastic (US).

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Nozzles...

Well, I put an order in with MatterHackers for 8 nozzles, 2 spools of filament, and a pkg of E3D silicone socks (the new design that leaves the nozzle exposed) late Friday. Due to the late hour, I expected the order wouldn't be processed until today (well... yesterday, now) and hopefully I might get it late this week.

Imagine my surprise when the better half walked in declaring, "You've got a package."

I needed something to go right...

Still haven't ordered a wrunch [sic]/spanner, and awaiting another spool from another vendor.

I wonder what ever happened with that MMU2 I ordered same time as the MK3 kit... 🙄

That's "MISTER Old Fart" to you!

Re: Nozzles...

MatterHackers is the 1st non-Amazon company that has startled me with how fast they ship. Not sure what they're doing right, but for a company serving a niche industry, they're pretty impressive. PrintedSolid and FilamentOne have also gotten things to me within a few business days. It's a great time to be a hobbyist!

[...] Imagine my surprise when the better half walked in declaring, "You've got a package."

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Nozzles...

MatterHackers is the 1st non-Amazon company that has startled me with how fast they ship. Not sure what they're doing right, but for a company serving a niche industry, they're pretty impressive. PrintedSolid and FilamentOne have also gotten things to me within a few business days. It's a great time to be a hobbyist!

Too bad MakerGeeks can't seem to figure that out! 😐

https://www.google.com/search?q=makergeeks+bbb&ie=utf-8&oe=utf-8&client=firefox-b-1-ab

Given what I've learned trying to amass a list of filament vendors (comings & goings), and stories I keep hearing/seeing about failed printer ventures on crowdfunding sites, I expect competition is only going to get fiercer in the short term (and of course customer service plays a major role). What I don't know at this time is whether the "hobby" has reached saturation yet or not, as many/most hobbies do after an initial (or cyclical) "fad" growth.

That's "MISTER Old Fart" to you!

Re: Nozzles...

Take this for what it's worth.

I bought a 23mm open ended wrench for changing nozzles. You avoid any contact with the heater and thermistor wires.

It's a tight fit, especially when there is plastic on the wider end. But it's not hard to secure the heater block. And 23mm isn't as common as you'd think.

Re: Nozzles...

Take this for what it's worth.

I bought a 23mm open ended wrench for changing nozzles. You avoid any contact with the heater and thermistor wires.

It's a tight fit, especially when there is plastic on the wider end. But it's not hard to secure the heater block. And 23mm isn't as common as you'd think.

Thanks for the advice. I'm planning on using an adjustable crescent wrunch for the time being--it doesn't care about Imperial or Metric. I have a small one that can get into that space and securely hold the heater block.

That's "MISTER Old Fart" to you!