My first two days with the Palette 3

I was super excited to see the new Mosaic Palette 3 show up on my doorsteps a couple of days ago, after a long wait.

Now on day 2 of my "experience" with it, it's been nothing but depressing.

Setting it up wasn't too hard to figure out despite best efforts made by Mosaic with their documentation to obfuscate this process…

Loaded two filaments for the test print. Nowhere in the onboarding does it specify what filament type to use but I assumed PLA was a safe guess. It went through a lot of filament movements and eventually filament got loaded into the extruder, at which the Palette claimed no filament movement was detected. When I unloaded everything, the filament strand was broken at the splice site, not a good sign.

But wait, it gets better.

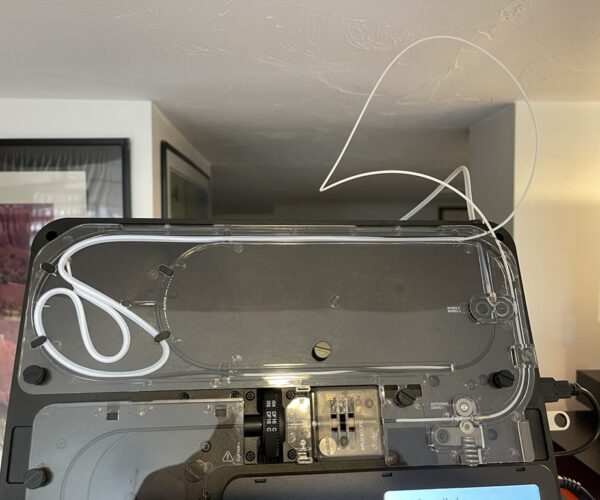

The next attempts all ended up with this:

Four times, cleaning up the mess, resetting the Palette to original settings, going through onboarding, ending up with the same picture. At point I had realized that the filament never made it into the outgoing tube and even though I didn't see anything visibly wrong, I took out the brass fitting and reseated it. Lo and behold, the next cycle of resetting, onboarding, and test printing made it all the way to filament going into the extruder, and in fact the test print started. After 10 minutes, when the display claimed that 30% had been printed but still 1h 15 min to go (how that math works is beyond me), I got this message on my Mk3S+:

Unload filament? Huh? At this point I gave up.

I'm trying to work with support but the only option to communicate with them is asynchronously by email, which is killing me.

Oh well, I'm not willing to give up hope yet but at this point it looks like the Palette is not going to be any more fun than the MMU2.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

I must admit that's the first time I've heard about Palette... seems to be quite interesting add-on for 3D printer. Didn't check the price, but I can imagine it's not that cheap.

Thank you for reporting about it.. hopefully you'll make it run as expected 😏

[Mini+] [MK3S+BEAR]

Hi. fuchsr

IIRC when I got the Palette2S Pro, the instructions told you to turn the filament sensor off....

could I suggest you try turning the Prusa Filament sensor off, and relying on the filament sensors in the palette.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

sensor

Yes, the filament sensor needs to be turned off on the Prusa

RE: My first two days with the Palette 3

I just got a Palette 3 and having very similar issues with my MK3S. The main thing is that when the filament is loading into the extruder it tells me to feed ~84mm but does not detect that it's happening when I move the extruder using the nob on the printer. Using "Smart Load" actually feeds the filament through the extruder but then says "no filament movement was detected". I'm kind of stuck at this step and can't get any further.

BTW. I have the filament sensor turned off.

RE: My first two days with the Palette 3

I actually fired it up just a couple of days ago. This time I made it all the way to the test print. Of course then it crapped out 70% through the print with a broken splice.... which makes me really wonder. Sure, you can do "splice tuning". But I have about 40 different filaments in use now and while I will certainly not use all of them for multi color prints, it still strikes me as a huge combinatorial issue to do splice tuning on all variations of filament pairs. I didn't think this through before I bought it. I just assumed they'd figured out how I get good slices most if not all of the time. And the filament I was using was nothing special, standard overture PLA.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: My first two days with the Palette 3

I finally did get it to print. My issue, it turns out, was that the first splice was failing and coming apart. Therefore the filament would get pulled into the extruder, but it would only pull the top broken off piece and the Palette therefore didn’t sense any filament movement. It’s a bit strange since the remaining splices seemed pretty strong. I switched to a different filament (the first was fairly old) and it worked.

I still only printed the key chain so far. Will try a more complex print in a little while.

RE: My first two days with the Palette 3

After a really long wait my Palette 3 Pro was delivered a few days ago and I have it working reasonable well.

Smartload:

Remove the filament sensor if you have it installed. It adds resistance to the filament and increased the distance between the brass fitting in the P3 and the extruder gears.

The length of the tube that goes into the extruder needs to added to the length of the output tube that you are using. I am using the short tube (57 CM) tube. I measured the distance from the start of the extruder input tube and found it to be 15cm. I came up with a rough value of 72cm for my output tube. In the calibration print, I used a custom length output tube of 72 cm. It was close and it got the filament all the way to the hot end, but not enough to have a full purge line. By experimentation I found for my printer 76cm provided a full purge line and started the print in the right spot to have the colors align properly for the calibration print.

Filament:

Using filament (Prusament and Mosaic) with a +/- 0.03 tolerance, I have made several prints with zero broken splices.

Using filament ( Several brands) with a +/- 0.05 tolerance, I have had zero successful prints and I lost count of the broken splices.

Now comes the reasonably well part.

There is a communication issue with the P3P and the Prusa Mini+. In long prints the printer will just freeze up. You can get the printer to move again by pausing/resuming the print on the P3P screen.

During the smart load process sometimes the the extruder motor doesn't start and the P3P displays the there is a problem message.

If you open the inspection door on the top of the extruder then is safe to restart the smartload. If the extruder motor isn't turning when it should and don't have the the message, then pausing and resuming the smart load will get the extruder move.

None of this happens when connect to a Lulzbot TAZ5 or the Prusa MK3S. This seems to be specific to the P3P/mini combination.

I hope that some of this may have been useful and I hope you get the P3 printing soon.

RE:

After a really long wait my Palette 3 Pro was delivered a few days ago and I have it working reasonable well.

Smartload:

Remove the filament sensor if you have it installed. It adds resistance to the filament and increased the distance between the brass fitting in the P3 and the extruder gears.

The length of the tube that goes into the extruder needs to added to the length of the output tube that you are using. I am using the short tube (57 CM) tube. I measured the distance from the start of the extruder input tube and found it to be 15cm. I came up with a rough value of 72cm for my output tube. In the calibration print, I used a custom length output tube of 72 cm. It was close and it got the filament all the way to the hot end, but not enough to have a full purge line. By experimentation I found for my printer 76cm provided a full purge line and started the print in the right spot to have the colors align properly for the calibration print.

Filament:

Using filament (Prusament and Mosaic) with a +/- 0.03 tolerance, I have made several prints with zero broken splices.

Using filament ( Several brands) with a +/- 0.05 tolerance, I have had zero successful prints and I lost count of the broken splices.

Now comes the reasonably well part.

There is a communication issue with the P3P and the Prusa Mini+. In long prints the printer will just freeze up. You can get the printer to move again by pausing/resuming the print on the P3P screen.

During the smart load process sometimes the the extruder motor doesn't start and the P3P displays the there is a problem message.

If you open the inspection door on the top of the extruder then is safe to restart the smartload. If the extruder motor isn't turning when it should and don't have the the message, then pausing and resuming the smart load will get the extruder move.

None of this happens when connect to a Lulzbot TAZ5 or the Prusa MK3S. This seems to be specific to the P3P/mini combination.

I hope that some of this may have been useful and I hope you get the P3 printing soon.

Note: The output tube length in my above comment applies to the Prusa Mini not the MK3S.

The hang problem was resolved by flashing the Palette 3 alt-firmware that was released to resolve issues with the Mini and MK3S.