MK3 & MK3S Prusa Heat Break

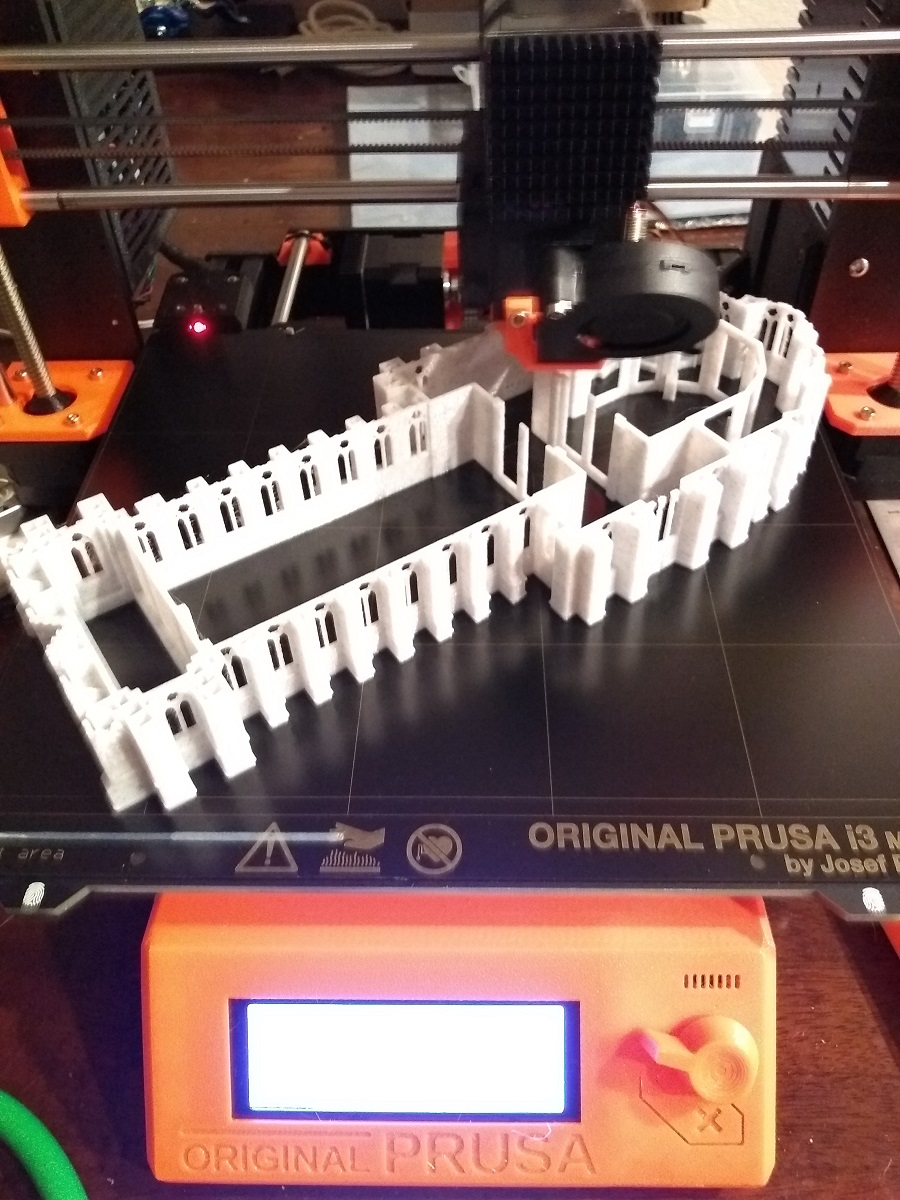

Well, after fighting yet another "weird" printing issue on a complex and large cathedral model ... I have to eat some crow.

There is a theory about that makes a claim the Prusa version of the E3D-V6 heat break causes problems with models having lots of retractions. I've been a strong advocate of Prusa and said I won't believe it until I see a cold pull with a 2.2 mm section.

Well, I found the evidence that compels me to say: they were right.

After a couple of fixes to my clicking print were exactly the same - both about 15 hours in and then 24 hours in - the filament I pulled has a 2.2mm section, and only the 2.2 mm section. The filament past the 2.2 mm section - farther in the heat break and nozzle - was melted away enough it came away with only a very fine spider web thread.

The result is the extruder was trying to push this 2.2 mm diameter section into the 2.0 mm section of the heat break and nozzle; but the upper 2.0 mm section is not hot enough to let that happen. I've restarted the print (the last foul was while I was sleeping) and I have increase print temp 10c in an effort to explore whether or not printing hotter is a solution. If I hear clicking, I will try to recover by increasing another 5c ...

Photos ... print is 15 and 24 hours in. Layer defects due to underextrusion were sufficient to cancel the print.

Re: MK3 & MK3S Prusa Heat Break

I have increase print temp 10c in an effort to explore whether or not printing hotter is a solution. If I hear clicking, I will try to recover by increasing another 5c ...

I'll have to dig up the thread where I was told about this to get it, but the video I was pointed to was specifically talking about significantly increased temps do get past the issue, but it starts degrading the print in other ways.

I didn't try different temps, but I did find the filament makes a difference. My silver Prusa (not Prusament) that came with the printer was what gave me so many problems. I ran Amazon, Superfilla, and Silk (good lord that stuff is garbage!) through using the same gcode and they all ran successfully without jamming.

Unfortunately no sooner did I get all the parts to rebuild my extruder with a straight heatbreak Prusa finally decided to send me my MMU (missing a part of course 🙄 ). I've been on the fence about if I'd actually install the MMU/MK3S, but my OCD couldn't resist a box of parts that needed assembling 😆 So now I have a torn apart printer waiting on a missing IR cable to show up...

Edit: Here is the post that put me onto the issue:

Been here. Went crazy. Found the following fixes:

1. The pin that holds the bondtech idler gear in place tends to back out on the MK3 printers. Press it back in. Some people put a touch of epoxy on it to prevent it from happening again. This guy resolved his jamming problem with this fix: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/another-heat-creep-jam-problem-t23781.html

2. Ditch the "Prusa" heatbreak and put a straight through or a MicroSwiss Nickle coated heatbreak in there. 3Dprinting nerd did a good video on this:

3. One day you should print out and use Butterworth Design's aligned extruder body. Idk why Prusa hasn't fixed this, but it helps dramatically for flexible filaments and PETG. It certainly will help with standarrd PLA as well. https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/modified-c1-r4-mk3s-parts-better-filament-path-and-t28334.html#p133076

Edit:

The filament sensor gets dirty over time which hinders it's performance. I try to give it a little blast of air every print to keep the dust off of it and occasionally I pull it out to clean it with a q-tip. I don't print with much transparent filament, but I print with white no problem. I've read other users having success with this solution too. Or heck...go for broke and print the Butterworth extruder body with the indirect configuration N4A (thanks Marin_au) and never deal with the sensor again!

Re: MK3 & MK3S Prusa Heat Break

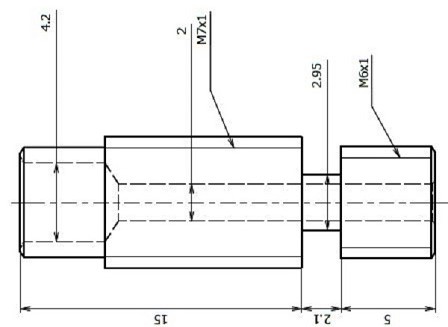

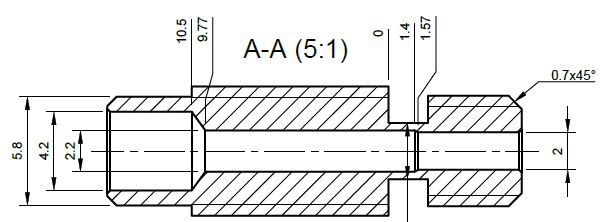

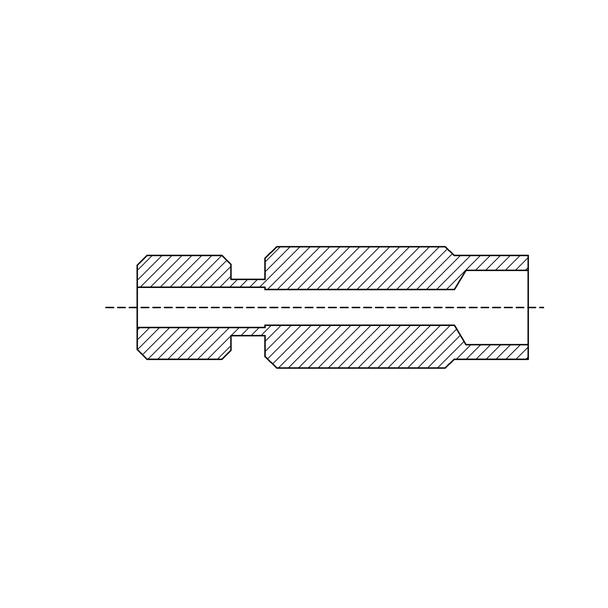

Interestingly, the MicroSwiss stepped heat break is totally different that the Prusa version. The Prusa is 2.2 mm from the feed side (PTFE down), and the MicroSwiss is 2.2 mm up from the nozzle side. Which is why the MicroSwiss is much less likely to see this specific problem (the nozzle is likely above the meltpoint at all times, whereas the heat break might be doing it's job and below melt point at the step).

E3D:

Prusa:

MicroSwiss:

RE: MK3 & MK3S Prusa Heat Break

Cool - can't create a new topic since I am a newbie now. Anyone find a way to change the forum post date format to MM/DD/YYYY?

RE: MK3 & MK3S Prusa Heat Break

Trying to create posts - just in case there is some threshold to create a new topic...

Towards the nozzle jams - tried printing the Riems at 220c, it failed, too. Remarkably: at 35.6 mm, whereas the first try failed at 35.4 mm ... Those layers are packed full of small separated areas requiring lots of hops. Might try another filament before the swap, too. Going to swap the heat break and do another test, just to confirm.

RE: MK3 & MK3S Prusa Heat Break

Wow - I can't believe how slow this "new and faster forum" is. It is taking about a minute between "Add reply" and the somewhat annoying whirling whatever at the top of the page goes away - followed by a bit longer wait to see the page update.

Prusa - if you are listening, I have a 2000 model Xeon with a 24TB 12 spindle RAID you are welcome to use.

RE: MK3 & MK3S Prusa Heat Break

Tim, let's give them a frw days to shake down the new system' perhaps it will get better once our accounts age enough to restore our privileges and established users?

RE: MK3 & MK3S Prusa Heat Break

I picked up a pair of titanium heat breaks from Amazon and they seem to work very well. Smooth bore polished. 1.75 straight through - I use a Palette 2 so I don't need any accommodation for an MMU2.

RE: MK3 & MK3S Prusa Heat Break

Ugh. I upgraded to the Mk3S MMU2S and am regretting it. Not a single successful print because of this problem. I've tried upping the temps 30 degrees C, adding thermal paste. I purchased the Sunon v1 fans and will be upgrading that next week but this is ridiculous.

Reminds me of when the Mk3 first came out and had the same problem. That was resolved by reworking the extruder body to increase airflow. Support said it wasn't a problem...until they said it was...

RE: MK3 & MK3S Prusa Heat Break

Ugh, I think I'm having this problem as well. Most of my prints have been failing since upgrading to MK3S + MMU2S. I never had any problems before the upgrade but now... basically almost every print stops extruding mid print (single color prints as well!).

When I open up the idler the bondtech gears ate away the filament so when I try to pull it out, it always breaks. If I try to push it down with a wire (or more filament), it won't budge.

I then need to grab my pliers and eventually manage to pull the filament up. It looks exactly as the first post in this thread.

What do I do? just the thought of downgrading back to MK3 makes me give up on the idea.

RE: MK3 & MK3S Prusa Heat Break

Sounds like the same problem; I have a pair of new non-Prusa heat breaks to try; at this point I am recommending everyone with issues like this contact Prusa directly via CHAT.

Prusa has a CHAT available in their STORE website. Log in like you are going to buy something and CHAT is available lower right of the screen.

RE: MK3 & MK3S Prusa Heat Break

I'm currently chatting with support but they haven't provided any useful guidance yet. I've also tweeted out a video of me fixing yet another clog: https://twitter.com/nunofgs/status/1122832531739566083

Notes:

- I've printed something almost every day for the past year — with no issues.

- I've had the MMU2 installed for months, but pretty much only used single-color prints since it was so unreliable.

- The clogs only started happening since the MK3S upgrade.

- I took great care to push the PTFE tube down as far as possible, and to lock it in place with the black tab. (during the upgrade)

- When a clog happens, if I try to push the filament down with a small allen key, it absolutely won't budge.

- To clear the clog I need to pull the filament up using pliers — it takes quite a bit of force to do so.

- During normal load/unload operations there is no filament grind from the bondtech gears — however, understandably, when a clog happens it'll usually grind the filament pretty much until it snaps.

RE: MK3 & MK3S Prusa Heat Break

Quick update on my issue: I managed to figure it out!

In my case, I always print in an enclosure. Thee MK3S extruder upgrade "hugs" the hotend quite closely and apparently it was enough to make the plastic grind and break, causing it to stop extruding. (I'm sure the warm weather lately didn't help)

This explains why the prints always failed 30 mins to 1 hour in, but it was never a specific amount of time.

I'm now printing with the door open and haven't had a failure yet. Now... on to getting this MMU2S to work properly :/

RE: MK3 & MK3S Prusa Heat Break

Bit of an Own Goal... issue!

Glad to hear you resolved the problem, good luck with the MMU2

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: MK3 & MK3S Prusa Heat Break

As an update: replacing my Prusa supplied heat break with the the stock E3D-V6 version, absolutely no printing issues on the same 76 hour part that failed multiple times on two prior attempts nor problems with the two prints I have done since.

I also have the titanium MicroSwiss version, but will probably wait to try it -- maybe when I get around to doing my Mk3S upgrade.

RE: MK3 & MK3S Prusa Heat Break

Quick update on my issue: I managed to figure it out!

In my case, I always print in an enclosure.... Now... on to getting this MMU2S to work properly :/

I know this is an old thread but I'd like to know how you're doing now with the MMU2. I had been using my Prusa MK3S+MMU2S for several months without problems, and then recently the hotend would clog for no reason I could think of. I don't use an enclosure. The problem isn't the MMU2S; there's very little friction since I replaced all my feed tubes with 3mm inner-diameter PTFE, and because there's little friction, I had to create new auto-rewinders that pull very gently lest they pull the filament right out of the MMU.

Prusa thought the heat break may be overheating, because the printer prints fine for up to an hour and then jams, suggesting a thermal problem, and suggested re-applying fresh thermal paste. Not only did I do that, but I also replaced the heat break and nozzle. I documented stuff I tried in this post in another thread. I'm still using a MK3S heat break with the stepped 2.2-2.0mm bore, not the straight 2mm bore, because I see commentary that this is necessary for the MMU2S, but I am not sure why. Even so, why would my printer work fine for six months before the MMU2S, fine for the next six months with the MMU2S, and then start jamming?