Melting/drooping fan shroud

I have a mk3 that is upgraded to a mk3s+mmu2. I have printed the fan shroud in Prusa ASA (galaxy black).

Previously, when printing PETG, the ASA fan shroud has slowly deformed (sagging on the right by about 1-2 mm). Now I'm printing some large items using Prusa ASA (natural) and stock prusa-slicer settings, and the shroud is drooping all the way to where it touches the print (on the right side, near the layer fan and the Pinda).

Is this expected behavior? It seems strange that I'm unable to print Prusa ASA on my mk3s+ with the stock settings, without the fan shroud melting. I can swap on a new one (nominally my 17 hour print won't get ruined in the interim). I have manually gone in and enabled the layer fan at 20 to try to cool the shroud from the airflow, and tried to push the shroud back up into place.

Any suggestions?

Thanks!

RE: Melting/drooping fan shroud

Does your MK3S+ have a silicone sock installed? I found it helps when printing using higher melting temp materials. I've not experienced a drooping fan shroud since installing an E3D silicone sock (non-pro version) a couple years ago. As an added bonus they help keep the nozzle and hotend heaterblock clean too.

RE: Melting/drooping fan shroud

@few

If you can, print one with PC Blend, and you shouldn't have to worry about it again for a long long time. I also print mine out of ABS and they last for a few month's if I'm printing ABS or Nylons and higher temp materials in an enclosure.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Melting/drooping fan shroud

I haven't tried using a silicone sock yet. I'll get one, it's a good suggestion!

I was concerned with the silicone itself potentially becoming an issue (sticking/tearing/drooping). I have coated my nozzles with WS2, and clean with paper towels between prints.

RE: Melting/drooping fan shroud

I have been trying to avoid using nastier filaments. I think I should try printing one from PC, as you suggest. Yet one more spool! 😉

RE: Melting/drooping fan shroud

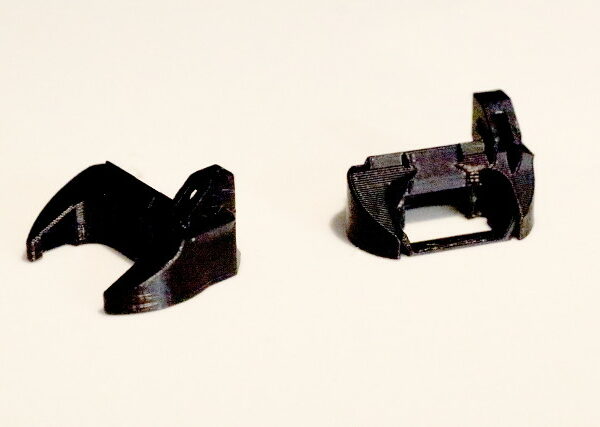

Ah the timing. I got home and found the shroud had fully broken off and my print was starting a nest. I'm not 100% sure it was ASA after all. It was one of the older single-side mounted shrouds. But to fit my ASA shroud (which is the newer double-held shrouds), I need to rebuild the E axis to R6/R7.

Thanks for the advice in the interim!

RE:

I am surprised Prusament ASA would perform so poorly. I had a Fillamentum ASA shroud for a short while. I don't think it behaved as badly (but if I remember correctly it did deform a bit after printing a while at high temperatures). In any case, I have now already for a good while a Prusament PC-Blend shroud and it doesn't budge a bit no matter if I print PC Blend at 285°C or something at 250°C. And I don't use a silicon sock on my Mk3s.

PC Blend is a bit demanding to print and only really suitable for not too large parts. If you can handle warping, print quality is good though. And that stuff is tough, great layer adhesion, super strong, besides being among the most heat stable materials an Mk3s can print.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE:

I've had very good luck with a remixed shroud, printed in Prusa(ment) PC Blend, and it's going on two years with countless PLA, ABS and PETg prints.

The stock shroud (ASA/ABS I assume) started drooping after a fairly long run of ABS prints, so I figured it would be as good as an excuse to try the PC Blend as any.

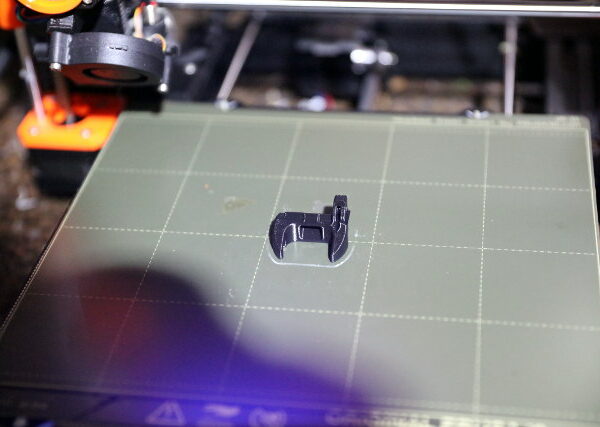

I printed both the original and the remixed one in PC Blend before I took the machine down to replace it, and made the decision of which one to use (original or remixed) in real time as I did the repair/replacement. I decided on the remixed one and kept the original design one in the 'crash kit' which I keep on hand.

No drooping issues ever since.

RE: Melting/drooping fan shroud

It's simple, Prusa printers cannot print material that requires higher temperatures - very small parts can be printed - larger ones will melt the fan schrout no matter what material it is made of. A silicone cap only delays the melting. This happens even faster if you print in an enclosure, then it even happens that the pinda holder bends.

That Prusa printers can print material at higher temperatures is a pure marketing lie.

RE: Melting/drooping fan shroud

I can not confirm your claim. I have printed a number of decently sized PC-Blend parts on my Prusa inside an enclosure, with my PC-Blend shroud and could not detect the slightest sign of drooping or melting. The shroud still looks just like new. And the PC-Blend temperatures are very close to the specified temperature limits for both hotend and heatbed - without silicon cap.

Maybe you have a very well insulated, compact enclosure and reach temperatures above 50 °C inside, but in mine I could not see any issue. If I had seen an issue with the Pinda probe, I had reprinted that part in PC-Blend too. No need for that so far.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Melting/drooping fan shroud

Can't comment on any suggested 'marketing lies', but I've not experienced any notable issues with high-temp printing during 4-5 year ownership of a Prusa MK3. My two MK3S machines have each only had the fan shroud replaced once or twice, which seems fair enough considering all the ABS and ASA models that've been printed. The extruder body on one machine has begun to deform just a little, but it hasn't stopped the printer from printing fine and it's fairly easily rectified by a service in which the deformed part is replaced.

RE: Melting/drooping fan shroud

According to Prusa materials table, Fillamentum ASA has a deflection temperature of 93C, while Prusament ASA is rated only at 86C. So, for people unwilling/unable to print PC, Fillamentum ASA seems more suitable for fan shrouds. Besides, there’re some brands of ABS rated 95-100C

I think also that using a silicone sock, as you suggested, helps to increase noticeably the lifespan of a shroud, even printed with Prusament ASA.

Of course, the ultimate material for a fan shroud is the new Prusament PA11-CF, with a deflection temp. of 192C, A bit overkill, if you ask me... 😊