Loss of accuracy?

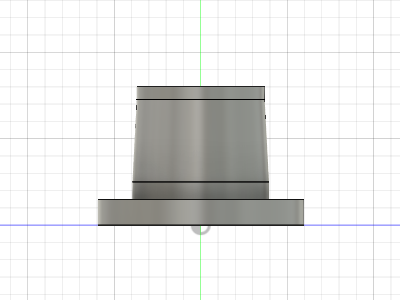

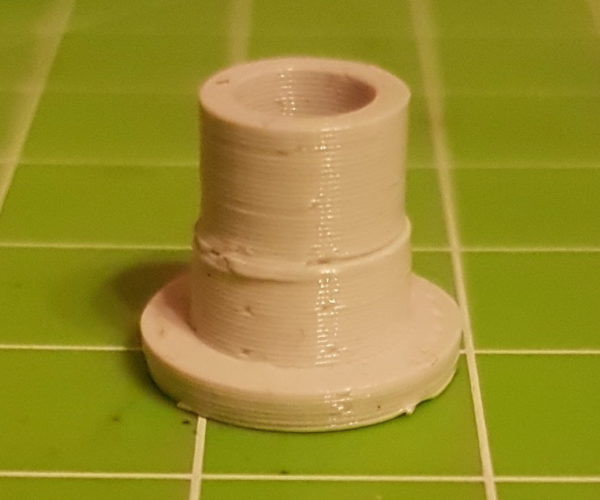

I recently started working on a mechanism in Fusion 360 that included friction fits for ball bearings. What I designed worked as intended.

Fast forward to recently. I print in PLA, and I had some kind of issue with any filament except for one (which hence has been my go-to for a while). I did some research and decided to replace my heat break with an un-modified version. I did that, it worked better, then it happened again. So I disabled the filament sensor and things went smoothly. (I should have tried that before).

Anyway, here is the problem (TLDR): the parts I printed successfully before do not work anymore. I did have to resize them along the way, too, but the sizes are off. And a piece that should be at an angle has a step in it. See pictures. (I have printed other things, larger, more organic, and they work fine. Cannot speak to their accuracy, though).

I can tell that there is something wrong with the print, but going through troubleshooting lists has not yielded anything I could pinpoint.

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)

RE: Loss of accuracy?

I don't think many people here will be able to answer you, we do not have MINI yet. Do you have one already? If you received one as part of beta test or review unit, it may be better to ask support directly. It does have custom hotend AFAIK, you may need to wait few more weeks until people receive their MINIs, do a teardown and will be able to advise here.

RE: Loss of accuracy?

@dominic-b4

Are you sure you are posting on the correct thread?

Can you let us know please, what printer are you talking about and how should we interpret "decided to replace my heat break with an un-modified version".

So you already had installed anything non standard before the troubles started?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Loss of accuracy?

@zoltan

First off, you are right! This is in the wrong place. I have the MK3! So sorry about that! Can you move this, or should I simply re-post in the appropriate thread?

As for what I modified, like I said I have printed for a while, but only used one brand and color of PLA filament - all the others gave me issues, in that the print would be interrupted and the printer would ask me to change the filament. I then did what someone recommended in this thread: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/prusa-edition-heat-break-easily-jam-clog-with-pla/ . That only partially worked so I also disabled the filament sensor. Now I can print with any PLA filament (at least from those I already had), but the accuracy has suffered.

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)

RE: Loss of accuracy?

I think you need to cross check the thread you have posted in.

RE: Loss of accuracy?

@payalguptha379

I did and realized my mistake - but I wanted to wait for a mod to let me know whether I need to re-post this in the appropriate place or they can move it. As far as I can tell, I cannot delete this thread here myself.

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)

RE: Loss of accuracy?

@be-inspired-with-dominic

moved to correct thread

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Loss of accuracy?

Size changes in parts can be directly related to the last XYZ calibration that was done; and any changes in belt tension.

XYZ cal sets the motor steps per millimeter based on bed calibration points (metal embedded into the FRP material).

Belts, while very good, stretch and wear. Changes in belt length and thickness affects the calibration result. Thus, gcodes that used to print to scale at the correct size, no longer print to scale properly.

As for the new "step" in your part, zip and post the STL model you are slicing from. And, while you are at it, zip the exported 3MF project.

RE: Loss of accuracy?

3MF is really important. You changed the model - and a missing layer can show symptoms like you have.

Folks here can take a look.

RE: Loss of accuracy?

I did run an XYZ calibration after replacing the heat break. I have not yet checked my belts - will do that after work.

And here is the .stl and the .3mf - File_Dominic

Thank you!

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)

RE: Loss of accuracy?

Your model checks out. I tested it with 3D Builder - no errors found.

RE: Loss of accuracy?

I don't understand why you have Supports turned on. This model has no need of supports.

Personal preference: for the work I do, I always use Quality or Detail rather than Speed.

RE: Loss of accuracy?

@robert-rmm200 Thank you for checking!

I left supports on because I thought it would not make a difference. My thinking was that the slicer checks whether they are needed, and in this case would deliver the same result as if I had turned them off.

I will try the other presets later to see whether that helps.

Is it possible that replacing the heat break has somehow altered the material flow and should be accounted for in some setting or other?

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)

RE: Loss of accuracy?

Reading the project file in PrusaSlicer settings:

- print set up default, why?

- what do you have set a default FFF printer instead of MK3 printer? is there any purpose or only mistake?

- generic PLA what kind of PLA is it?

- did all troubles come after the heat break change?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Loss of accuracy?

When I open his files, I get Original Prusa i3 MK3, which is fine.

If it really shows default FFF printer, that could cause issues.

I am just hoping someone else gets a chance to print his STL. That will show a lot.

RE: Loss of accuracy?

Sorry it was my fault, I had only MK3S in my printers portfolio

0,2mm SPEED MK3 profile - not the most accurate set up, the print should look slightly different anyway, will try tomorrow morning to print with Prusa PLA

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Loss of accuracy?

I printed the part three ways: 0.20 mm SPEED, 0.15 mm Quality; then after being unhappy with those tried 0.15 mm Quality with Detect Thin Walls (very slow perimeters).

The last method seems to provide the best result.

I only wish I understood better exactly what Detect Thin Walls is doing.

RE: Loss of accuracy?

@tim-m30

That's interesting, thank you! I just sliced the model in both 0.15 versions, and it occurs to me that the one with "detect thin walls" takes 7:30 instead of 8 minutes. I'll give it a try later!

@zoltan

To answer your questions, I am using PLA from a German supplier that gave me good results - but only the color "grey". I have no idea how to be more specific about it, but it is no "special" PLA as far as I can tell. This is the filament that worked well all the time, as opposed to pretty much every other PLA I tried (mainly metal effect, copper and gold, and from Prusa IIRC). With any other PLA, the print would stop after 1-2 layers, it would start beeping and demand a filament change. Once I did, another layer or two, and the same would happen. I eventually read about the heat break, got a stock one, replaced it, and things improved slightly, but not much. So I disabled the filament sensor. Now I can print every PLA I own, basically. TLDR: pretty basic PLA.

Another thing I find interesting. I have been working on this mechanism for a while and started out with slightly bigger bearings, and thus this part was bigger, although not by much (2mm in diameter, I think). I never had any issue with that, and I mainly used 0,2 SPEED for testing. Apparently, there was a threshold where that geometry stopped working with that preset.

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)

RE: Loss of accuracy?

Take this as anecdotal: I find my surface finish is best at .20 Quality. I.E., half the nozzle diameter. Works great for big surface area, like boxes.

For lithophanes, I use .15 Detail which seems to work out well.

RE: Loss of accuracy?

@robert-rmm200

That's good to know, thank you!

Update: printed the part in 0.15 with thin walls detected and it works! Currently testing 0.2 with detect thin walls for comparison (prototyping speed).

Remember to Be Inspired!

Standard MK3 (heat break replaced with standard model)