Looking for advice

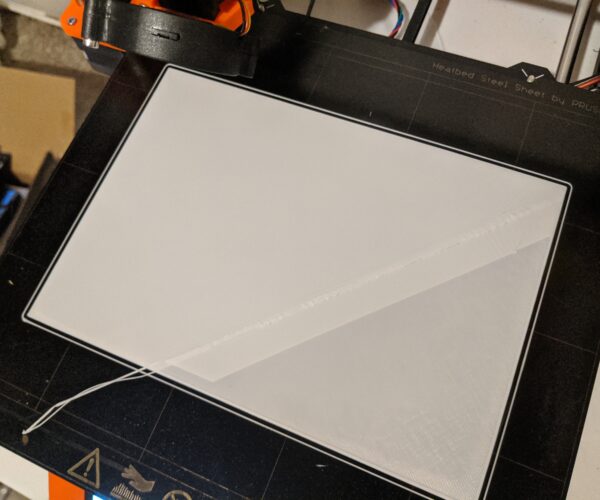

Looking for advice, this happened on the second layer of my recent prints. I've tried a few times. It seems like what happens when the bed bumps into something that doesn't move out of the way, had this happen on another printer. Except there's nothing to bump into. I wasn't around when the printer did this but after the first two fails (this is the third) I checked up every 10 minutes or so. The printer didn't register any errors, just keeps on chugging a few centimeters off... Any idea what could cause this? I can include the stl/gcode if need be and any relevant info about my setup, just let me know what you want to know. It's an mk3 printing PLA at 205 C at a 0.3 mm layer height.

Best Answer by vintagepc:

Disable your filament sensor. There is a known bug with false runout detection and long straight print segments like that. (It should be fixed in the upcoming 3.9 firmware).

RE: Looking for advice

First of all 0.3 layer height with 0.4 nozzle can be problematic and is not advised.

1. Your first layer is too low. Maybe do 0.2 layer height for the first layer and make sure no waves are being generated.

2. Slow down your print or increase the extruder temp. I've seen weird results with this setup and maybe this is one of those.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Looking for advice

Disable your filament sensor. There is a known bug with false runout detection and long straight print segments like that. (It should be fixed in the upcoming 3.9 firmware).

RE: Looking for advice

@vintagepc

This seems to have been the issue. I finally found elsewhere a video of this same thing happening to someone else with disabling the filament sensor as the fix. Also found that matte white filament (what I was using) also has issues with the sensor without the known firmware issue.

RE: Looking for advice

@nikolai-r

Thank you, I had not known that the layer height could be a problem. Do you know where I can read about ideal layer heights vs. nozzle diameter? Filament sensor disabling seemed to work for this issue, the print is still going but made it a few hours without issue.

RE: Looking for advice

there is a general rule of thumb that you should not exceed 80% of the nozzle width.

if you look at the Prusa Slicer settings,

0.3mm layerheight for a 0.4mm nozzle is described as 'Draft mk3'

for the 0.6mm nozzle Prusa slicer describes the 0.3mm layer height setting as Quality! (the Mk3 and Mk3S have profiles up to 0.4mm Layer height!)

for the 0.25mm nozzle, there is no option for 0.3mm layer height!

Oddly the Mk2S printer has a 0.35 'Fast' Profile... but the Mk2S has a completely different extruder setup...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Looking for advice

Concur, nothing wrong with 0.3. I did my entire LACK enclosure at that value, except where necessary for overhangs.

RE: Looking for advice

Concur, nothing wrong with 0.3. I did my entire LACK enclosure at that value, except where necessary for overhangs.

You have a lot of experience. I'm pretty sure you could even make a good slice with 0.4 layer height. 😉 The 70-80% rule of thumb is a good best practice for regular prints. I'm trying to not exceed 0.25 layer height with the 0.4 nozzle. Otherwise I have to pay attention to filament temp and speed.

Back to the topic: the firmware bug explains the shown behavior. It almost looks like Y-shift but then it should be visible on both sides, not only on one.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram