Level bed, uneven first layer

I've been on a journey to get my Prusa's first layer even and smooth. However, I cannot seem to achieve this. I'll lay out what I've done, my thoughts, and then hopefully you can suggest the best course of action.

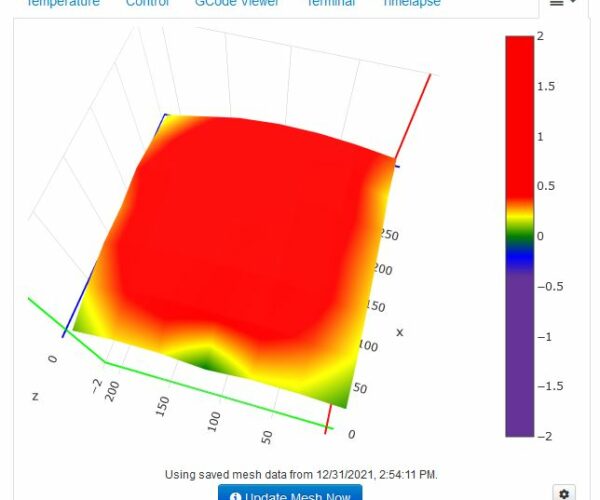

My prusa's original bed mesh level looked like this:

The red values were around 0.4-0.6. And while it was like this, I was unable to print much of anything. The little I could print had to be small, slow, and push out extra plastic just to get it to stick to the bed well.

After some research, I went and followed this video on how to install the nylock mod and level the bed. Now my bed looks like this:

I'm pretty happy with these values, and feel they should now produce a consistent first layer assuming I have the z offset set properly. My live z adjust is set to -1.475, and most of the squares seem to be coming out alright, but the middle left square is awful, way too high. The bottom right of my bed is lower, as the skirt usually has trouble sticking there. Here is the bed calibration test without any bed level compensation through software:

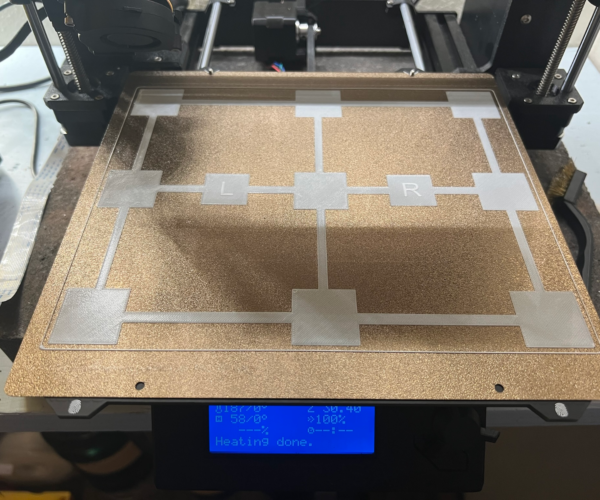

I am not using the default plate that came with the printer, insteadI have this one from Amazon. I have printed on it successfully, many times in fact before I started this journey, so I don't think the plate is warped or has any issues.

Here's what I've tried so far to fix the issue.

- Disassembled the extruder - I thought maybe there was a clog in the PTFE tube, gear, or hot end that was causing the filament to come out inconsistently, presenting as an uneven layer, but actually a mechanical fault. I found nothing wrong, and filament passes through freely and as expected.

- Multiple nozzles - I had the default nozzle on for a while, then I've switched to several others. Each one has the same problem, and I've checked to ensure they aren't clogged.

- Tightened screws - I tightened every screw I could reach to ensure it was on properly. The ones under the bed, and that are difficult to access I didn't touch because I don't have a tiny screwdriver

- .Cleaning the Plate - I've cleaned the plate with IPA several times, even used fine grain sandpaper to see if I could revive the texture, but none of it helped.

- Bed Level Calibration - I've adjusted these values all the way up to 100 (over several prints) to try and get the middle looking just right, and the left side sorted out, but no matter the values I put it, I can't get it level.

- Physically raising the left side - I've brought up the left side of the bed, quite a bit, to see if that would help, but it continually is too close to the nozzle compared to everything else.

Here is a big square I printed to show that, even though the bed calibration looks ok, the printer is essentially unusable:

Trying to print anything bigger than the middle section that's clean on that square results in destroyed parts of the print. Obviously I'd like to be able to use the entire printer, not just a few centimeters of it directly in the center.

My conclusion is that the Pinda sensor is malfunctioning. Somehow it is reading the values when it runs the mesh level, and then doesn't actually compensate for those values when printing. I've no idea if that's possible, but it seems like it's the only thing left. Should I replace the sensor? Should I reach out to Prusa directly and get support and see if I can replacement parts? I've heard they have good tech support, but haven't had to contact them before. But I've been at this for weeks now, and I'm slowly losing hope of ever getting it working.

I've run out of ideas and things to test and tweak. Any suggestions would be greatly appreciated.

RE: Level bed, uneven first layer

If you built it yourself from current Marlin source, using the example config, it should be right.

I've had great success using the UBL routines in preference to the default bi-linear, but have never bothered to dig into the underlying code to understand why it behaves differently below the surface.

Yes, I was referring to the prebuilt firmware that Creality provide for download from their site. You're not using that it seems, so that isn't the issue.

RE:

I just did a run (with Z_SAFE_HOMING activated, to see if that would change anything) and it turns out that, when probing the lowest point in my bed (which for me is the center, thus any time homing) I would hear almost like a slight skipping sound, but the probe would probe successfully.

It turns out that 0.5mm of a gantry sag is enough for my right roller to bottom out and hit the frame eeeeever so slightly on the right side, so BL Touch would try to compensate, but it would hit the frame on the right side on the lowest points which meant it wasn't compensating enough.

Leveling my bed at a higher point (turning all the screws higher so at the lowest point my gantry would still have about 0.5mm of play to go) did solve my issue where some points of the bed were too far, but I still seem to have an issue where the leftmost side of the bed is too close?

It's weird because it seems to be only on the left side, where my probe couldn't reach (because it's mounted on the right side of the extruder assy). Anyway, I'm going to try removing that 0.5mm difference in the X gantry sag, and I will report if that makes any difference, but I doubt it.

RE: Level bed, uneven first layer

You start saying:

The little I could print had to be small, slow, and push out extra plastic just to get it to stick to the bed well.

Later you state:

I have printed on it successfully, many times in fact before I started this journey

Which one is it? Did you have a working setup and "started the journey" anyway or did you never have a working setup to begin with? This is mutually exclusive and important for troubleshooting.

Your PINDA is obviously working ok, since you get the mesh - so no point in replacing it. PINDA does not correct for anything, it's just the sensor used to get the mesh data. During printing PINDA does not do anything, the printer (firmware) is using the mesh to correct the z-position. Which leads to the next question:

Do you have an ORIGINAL Prusa MK3 running the original firmware? Or do you have a clone running something else? If so: No point in contacting Prusa support. Same goes for the PEI sheet, you can not expect Prusa to support that.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!