Lemon printer? Nozzle leaking after nozzle replacement.

Just installed a new tungsten 0.4mm nozzle and followed the instructions. Disassembled hotend, cleaned it, installed nozzle flush with the heat block, unscrewed quarter turn and installed the heat break. Heated to 285 and gave it 1/8th turn when at 285. Got one six hour print and it's leaking from between the nozzle and block. This is my fourth time disassembling my hotend because it's dripping onto the print after a few hours causing either layer shift when my y belt skips from running into the blob or just ruining the print altogether.

I just replaced all the bearings and rods because the old rods got scratched up by the bearings within a week of printing as well. I've had this printer 6 months and I'm already 300$ in the hole replacing parts on a ready to go printer.

Did I get a lemon? I've had the words two years of my life and finally scraped together enough money to go back to school and provide for my son and my most expensive piece of equipment is now non functional once again. Wtf do I do?

Any advice will help Ty.

Not old till you hit triple digits...

-Güber McSanchez.

RE: Lemon printer? Nozzle leaking after nozzle replacement.

Just installed a new tungsten 0.4mm nozzle and followed the instructions. Disassembled hotend, cleaned it, installed nozzle flush with the heat block, unscrewed quarter turn and installed the heat break. Heated to 285 and gave it 1/8th turn when at 285. Got one six hour print and it's leaking from between the nozzle and block. This is my fourth time disassembling my hotend because it's dripping onto the print after a few hours causing either layer shift when my y belt skips from running into the blob or just ruining the print altogether.

If it's leaking molten filament around the nozzle, the junction right above the nozzle is not tight and/or not solid. That's really the only place such a leak can occur.

I would carefully inspect all components, making sure that the lower end of the heat break (as well as the new nozzle) has no protrusions or rough surfaces that may allow molten filament to leak through.

Also, if there's crud in the threads of the heat block, this may prevent a good tight seal, and give the false impression that everything is tight.

Remember that there's quite a bit of pressure in the extruder, and it does not take much to force the molten filament out of whatever exit passage it can find. Normally the only exit is through the nozzle, but if there's another opening, however small, the molten filament will find it.

RE: Lè cleaning.

I gave the whole hotend a good clean with 90%isopropyl, q tips and a brass brush. The threads had minor carbon speckling in the deepest part of the grooves but the nozzle threaded in easily without tools. I cleaned the touching flats on the heat break and nozzle and no light peeks between when I hold them together. I read somewhere that cpu paste can sometimes help. Or I over torqued the heat block and ruined the threads.

Edit, Also Ty for the quick response.

Not old till you hit triple digits...

-Güber McSanchez.

Follow up

https://dyzedesign.com/shop/nozzles/tungsten-carbide-nozzle/

Just to idiot check myself. This is the nozzle I got. 1.75mm m6 type.

Not old till you hit triple digits...

-Güber McSanchez.

wrong nozzle type

https://dyzedesign.com/shop/nozzles/tungsten-carbide-nozzle/

Just to idiot check myself. This is the nozzle I got. 1.75mm m6 type.

That's wrong nozzle.. you need E3D V6 nozzle type, which has 1.5mm longer thread.

[Mini+] [MK3S+BEAR]

RE: Figures.

Murphy strikes again. Thank you very much for the help. Do you perchance know where I can get a correct tungsten nozzle?

Just checked the measurements on both nozzles and they're identical give or take 0.1mm length wise.

Not old till you hit triple digits...

-Güber McSanchez.

RE: Lemon printer? Nozzle leaking after nozzle replacement.

Amazon has them, at least in the states.

Nozzle size.

So I just checked the threads and they're identical. The original brass one is 0.55mm longer according to my mitutoyo. My Olson ruby from prusa is also 0.5mm shorter than my stock brass nozzle. Thread pitch is identical on all three. Overall length on stock nozzle is 12.50 and my tungsten one from dyze is 12.45mm overall.

Should I just buy a new heater block and hope for the best?

Not old till you hit triple digits...

-Güber McSanchez.

RE: Lemon printer? Nozzle leaking after nozzle replacement.

So I just checked the threads and they're identical. The original brass one is 0.55mm longer according to my mitutoyo. My Olson ruby from prusa is also 0.5mm shorter than my stock brass nozzle. Thread pitch is identical on all three. Overall length on stock nozzle is 12.50 and my tungsten one from dyze is 12.45mm overall.

Should I just buy a new heater block and hope for the best?

If this were mine, I would carefully inspect all of the hot end components.

I would check very carefully for debris on the threads of the heat block and heatbreak. Unless you REALLY tightened by force, you should not have damaged the threads on the heat block. I would also check the lower end of the heatbreak, to be sure there's no debris or rough surfaces that might interfere with a good seal.

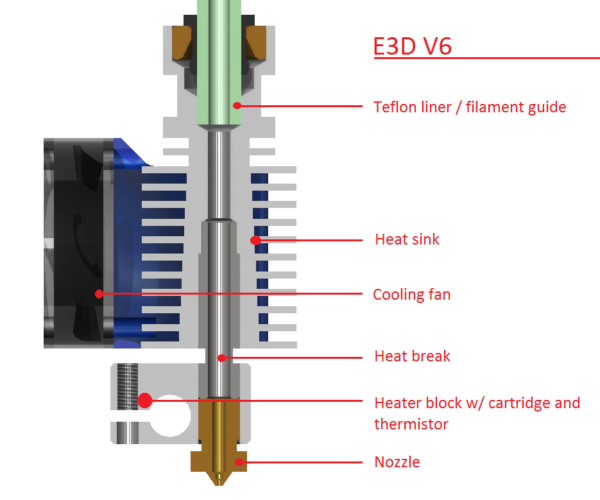

The last time I had my hot end disassembled, I cleaned and 'chased out' the threads on the heatbreak and the heat block and carefully removed all of the burned-on debris from the heat block. I'm sure you have seen the diagram below which shows exactly how the pieces are intended to fit (below).

The hotend cannot take a joke! 😉 It has to be assembled as shown, with no gap, even the slightest, between the top of the nozzle and the bottom of the heatbreak. You can see from the diagram that this point is the only discontinuity on the hot higher-pressure end of the system, and if a leak is to happen, that's where it will be.

There are some 3d printed 'torque wrenches' which may help you apply the proper torque when seating the nozzle (with all of the accuracy of a stopped clock) but I've lately just used the feel of two fingers on a small 'breaker bar' to seat them.

So I just checked the threads and they're identical. The original brass one is 0.55mm longer...

-I stand corrected: official documentation says thread length difference is 0.5mm.

As jsw pointed out (above), there's no joke with hotend -you simply need E3D V6 type nozzle.

[Mini+] [MK3S+BEAR]

RE: Brutal...

That diagram looks similar to ones I've seen yes. While I'm usually a bad punner (I have a baby boy so I have an excuse for dad jokes) I've noticed that the hotend has indeed zero sense of humor. I have a few torque wrenches that can go down to 10lbs ±5% for gunsmithing and jewelry.

Ty all for the advice btw. The only reason I measured is because I found out I have sh!t depth perception last year and until I get my glasses I don't trust my eyes.

It's amazing that 0.5mm makes such a difference.

Edit, does this mean my Olsen is out of spec? I havent used it yet.

Not old till you hit triple digits...

-Güber McSanchez.

Torque mayo.

On the torque thing also, I have Popeye (not kidding) forearms from my hobbies (blacksmithing etc) and am banned in most households from even touching mayonaise jar lids for fear over overtightening and depriving people of their sauce unjustly.

Not old till you hit triple digits...

-Güber McSanchez.

I would think that 0.5mm could be compensated for by simply screwing in the heatbreak a slight bit more, but I would agree that the best solution is to get the correct nozzle, which should be available within a few days at most.

Title

I'm going to install my ruby and see what that does while I order a new one. On new nozzles, do I need a new assembly for a volcano nozzle x? Or can you point me to some reading on the subject? I'm going back to "school" and teaching myself solidworks etc to work up to industry additive manufacturing and I've read a bit about higher temperature nozzles for higher print speeds but not much.

Not old till you hit triple digits...

-Güber McSanchez.

Volcano, Supervolcano, and BY nozzles are all different

Be sure you buy the correct nozzles for your E3D hotend. The Volcano, Supervolcano, and v6 all have very different geometry. E3D's technical drawings with dimensions are easily located on the web.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

This one?

Just took apart my hotend and damaged the threads on my heat break. Just to have spare parts (read, I don't want to clean the aluminium) I'm going to get another hotend. Is this the right one for my stock carriage? I can't remember if it's a 12 or 24v system according to the manual.

Not old till you hit triple digits...

-Güber McSanchez.

MK3 is 24v system.

Drop in?

Tyty.

Would this be a drop in replacement for my stock mk3s+?

Not old till you hit triple digits...

-Güber McSanchez.

Prusa version has longer cables

[...] Would this be a drop in replacement for my stock mk3s+?

No, that's the standard E3D V6 hotend. You want the Prusa version. It is available in the US from Filastruder. Pay attention to the notes on the PTFE tube.

Mind you, the parts from the standard version are interchangeable, but the Prusa version has different cable lengths.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Amazon has the Prusa version of the E3D hotend, or at least they did about a year ago when I ordered one to have a spare on hand.