Leaking Nozzle/Heat Block

Hi all, Need some help/advice. I have a just over a year old factory assembled Prusa i3 mk3. I have always had a problem with small black spots on long prints, which I now believe is a leaking nozzle/heat block. Reading on the forum it would indicate a incorrectly assembly hot end. But before tearing it apart I was considering the following options.

1) Heat to 285° Loosing and re-tighting

2) Heat to 285° Remove nozzle clean and re-install

3) Heat to 285° Remove nozzle clean and install New nozzle(maybe be time anyways)

4) Put printer in corner and get a drink

5) Forum recommendation ?

I just order a M7 socket, so I'm doing #4 now. Thanks in advance

RE: Leaking Nozzle/Heat Block

#4, always #4 ... and even IF you decide #1, do #4 first.

But, read and review the E3D-V6 nozzle replacement guide and the E3D-V6 assembly guide first. Both documents provide key details to prevent you from doing #1 many times and resorting to #4 afterwards.

RE: Leaking Nozzle/Heat Block

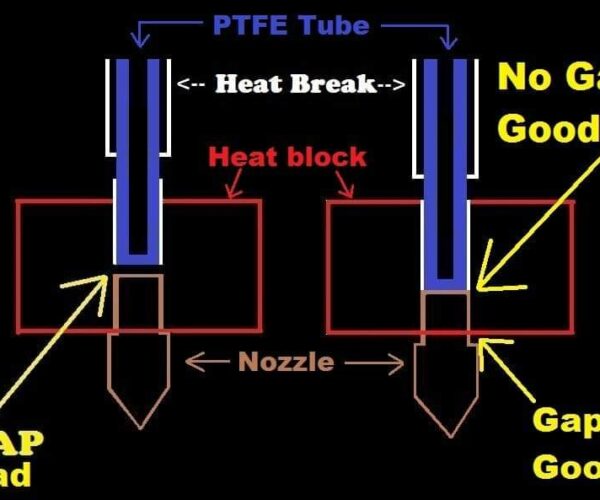

Most likely the heat break has gradually unscrewed from heat block. Think of the heat block as a fancy nut that is used to abbut heat break and nozzle together to seal their ends against each other. Nothing actually locks the heat break and cooling fins against rotation. The system relies on tension of nozzle against end of heat break to keep things in place (and sealed).

You will need to do all the work at temperature or else molten filament material will lock things together.

By the book you would take everything completely apart follow the E3D instructions for assembly. You may be able to get away with only a partial take apart and advance heat break into the heat block.

1. Cut zip locks that hold your heater wires or you may run out of slack

2. Heat to filament temperature and unload filament. Remove fan shroud shift parts cooling fan aside.

3. Increase temp to 285C

4. Use wrench to hold heat block in place

5. Unscrew nozzle completely.

6. Reach into empty nozzle hole and clean out old filament debris with counterclockwise twisting of q-tip.

7. Use wrench to twist heat block 45 degree onto the heat break. (viewed from bottom would be clockwise.) This should advance heat break a little further into heat block.

8. Hold heat block in its temporary 45 degree position with wrench

9. Install nozzle. It should now impinge against end of heat break a bit sooner. Tension to two fingers tight (still at 285C)

10. Let nozzle temp cool

11. Turn off printer

12. Undo hot end cover and straighten out the entire E3d hotend assembly to bring heat block back into normal alignment. The entire assembly including the cooling fins should be rotated, not just the heat block.

13. Redo zip ties.

Hopefully that does it.

RE: Leaking Nozzle/Heat Block

For emphasis.

BE SURE TO UNDO THOSE ZIP TIES! The direction of heat block twist in the above process will otherwise over tighten those wires and snap your heater cartridge and thermistor wires.

Alternative is to rotate heat block in other direction 45 degrees with heat off and hot end cover loose. That increases slack. Retighten hot end cover and when our rotate the heat block it comes out in standard position when you rotate it 45 degrees onto heat break.

RE: Leaking Nozzle/Heat Block

The nozzle and heat break are the important part of the connection. The heater block is only a part that the two thread in to, and the torque pressure must be nozzle to heat break.

Ideally, but impossible, is holding the heat break and torquing the nozzle to it. Since the heat break is fully threaded, with no wrench surface to grab, we use the heater block and hope the heat break doesn't spin when torquing the nozzle down. So the process always starts with the nozzle unscrewed from the heater block 1/4 to 1/2 turn, then tighten the heat break into the heater block until it is in full hand tight contact with the nozzle. Then the assembly is heated and while holding the heater block torque the nozzle to 3 nm.

The 45 degree spin mentioned by Prusa, and Guy, is advisable when this process has not been followed or it is known the torque process has allowed the heat break to "spin" out of the heater block; but is not always needed.

Ideally tightened, the heat break neck should be flush with the top of the heater block, and the nozzle about 1/4 turn away from the HEX bottoming out in the heater block.

But I defer to the E3D-V6 assembly as the primary and correct procedure for assembling the E3D-V6 assembly in the Prusa printer.

RE: Leaking Nozzle/Heat Block

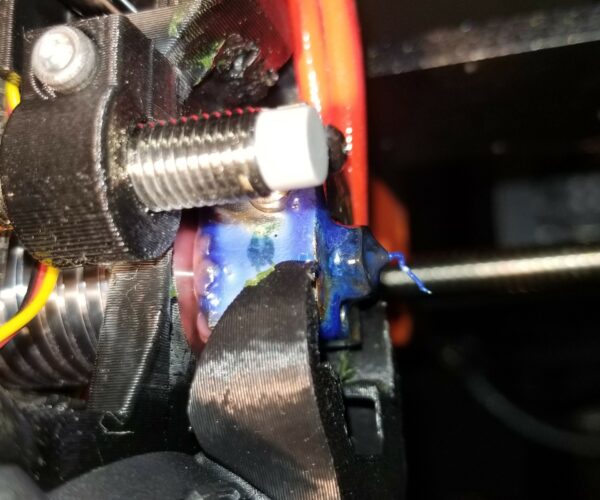

Bought a new heatend assembly because I accidentally cut a thermistor wire on the last one. Got the whole extruder put back together and replaced the standard nozzle with the steel 0.4mm nozzle. However, it still seems to be leaky not just at the nozzle (in blue), but above (in pink) as well. Even in some prints, the printer will leave behind what looks like little balls of smooth, melted plastic. Did I break the "heat break" trying to put the new nozzle on it cold? I figured I could replace the nozzle while it wasn't assembled to make it easier.

RE: Leaking Nozzle/Heat Block

@stricklandj1

It's possible you could have cracked he heatbreak.

if you assembled it cold, you may not have got the nozzle / heatbreak joint, tight enough

It's hard to see, through the molten filament, but it looks like your nozzle may be hard against the heat block, which usually means the heatbreak is not far enough into the heat block.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Leaking Nozzle/Heat Block

hello all,

I just upgraded from MK3 to MK3s. when i took the extruder assembly apart i saw that there was a significant leak. i then tried to clean it off as best as i could, then i completed the upgrade. When i followed the step by step in this thread to address the leak, i noticed that the heat block is extremely loose at 285c. The nozzle is tightened against the throat with about a 2mm gap until it reaches the heat block. the heat block moves very easily, but the heat break does not. (When i had it apart, i was able to unscrew the heat break from the throat to clean some of the plastic from the top of the block, so i don't think anything is cracked.)

I'm not sure of the best way to proceed. Do i disassemble the extruder again and try to clean all of the parts somehow? If so, how? The block is almost completely coated in plastic. Or is there a way to tighten the heat break at temperature? Is there something else that I'm missing? Any help will be greatly appreciated.

RE: Leaking Nozzle/Heat Block

The nozzle and heat break should be firmly seated together - torqued to 2nm. When this happens, the heater block is locked in place and can't move. It could be the heat break and heat sink were never snugged up - and thus the heat break, heater block, and nozzle are free to rotate.

RE: Leaking Nozzle/Heat Block

@tim-m30

the nozzle was tightened against the threaded tube inside the block with about 2mm of threading left on the nozzle. The fins of the heat break had come loose a 1/4 turn or so from the threaded tube that goes into the block(the throat?). What i ended up doing was removing the part cooling fan, the hood, and the support, then I removed the two screws that connect the extruder fan to the extruder cover. i removed the extruder cover, then rotated the heat break counter-clockwise with needlenose pliers covered with a shop towel(essentially blue extra thick paper towel). I brought the temp up to 285, then i used a wrench to tighten the block back into the heat break without loosening the nozzle. It tightened about a quarter of a turn. I'm running a test print now. It seems to have worked. The minor inaccuracies I was getting before the upgrade are gone as well.

RE: Leaking Nozzle/Heat Block

Okay - so we are on the same page:

Nozzle : Heater Block : Heat Break

Heat Sink with Collet:

And assembled heater block, with thermal gel on the heat break ready for screwing on the Heat Sink:

<note> : the nozzle is tightened to contact the heat break at this point, before adding the heat sink; final torque is done at 280c.

At no time should you apply torque to the heat break - the only wrench surfaces are the nozzle hex and the heater block.

RE: Leaking Nozzle/Heat Block

I had the same issue, black PETG leaking all over the heatblock, mostly from the top. At first i thought it was the extruder gears and what not that was acting up as little to no filament was extruding. I was trying to screw the heatblock back in, however as far as it went before it started to hit the extruder assembly (printed plastic parts) wasn't enough to get the nozzle to seal, instead it completely locked up against the heatblock.

Instead of taking the entire extruder apart I did the following:

With the nozzle removed/loosened, I first loosened the screw under the extruder motor (the left one) to remove all clamping pressure on the heatbreak. After removing the extruder fan, you can grab the heat break with your fingers from each side and screw it into the heatblock (while holding the hot heatblock with pliers). As you twist the heat break the heatblock should move up. Afterwards I put the nozzle BACK on and when it was fully tightened down there was a gap between the heat brake and the hex part of the nozzle and everything was sealed and functioning as normal.

In my case, the screw that clamped the heatbreak was already loose and likely contributed to my issue in the first place. In fact, I number of issues on my printer where simply loose screws/motor set screws. As a word of advise, check all your fasteners every now and then, especially if you frequently put your printer in the car like I did.

I hope this helped someone!

RE: Leaking Nozzle/Heat Block

How do you tighten the nozzle in the block without the machine screaming about a thermal anomaly and resetting? I just removed a nozzle with much trouble but replacing without the block moving is hard. I have yet to work out where I can grab the block without issue. I didn't touch any wires as I came at it from the other side, away from the heater and thermistor. But I am unable to do this without triggering the error. How doe the MK4 get past this? I see it's a just a simple operation on the MK4. What is the design change and why can't it be backported to the MK3?

Recent versions of the M3* firmware have a 'Nozzle Change' function (LCD menu) which turns off the thermal protection and handles some of the heating for you.

I use two thin bicycle spanners to hold the block and (un)screw the nozzle.

Cheerio,

RE: Leaking Nozzle/Heat Block

Ah. I was not using that mode, just trying to deal with a leak. Now I know…