Intermittent Under-extrusion During Large Layer Heights

Hi everyone,

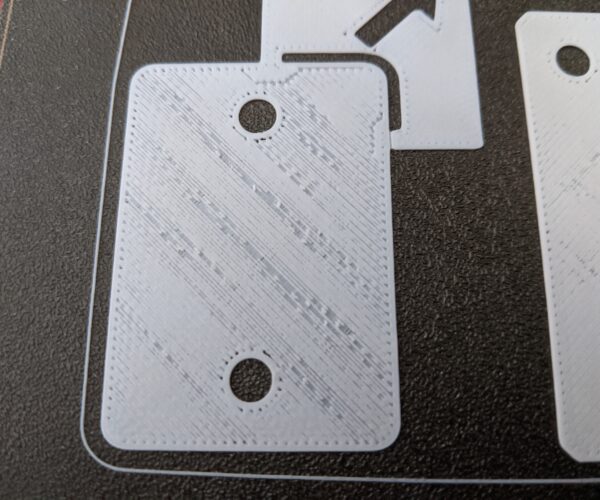

I have a Mk3S equipped with an MMU2S. Over the past week, I have been trying to print the updated Lack enclosure for the MMU2S+Mk3S setup. However, I seem to be experiencing some sort of intermittent under-extrusion during the prints. See the attached photos for images of the problem. The first two showcase the issue in white PLA and the third shows the issue in a different brand and color of PLA. The only modification to my hotend is that I am running a 0.4mm Nozzle X from E3D.

Prior to this set of prints, I had successfully printed small wall-mount for HTC Vive Lighthouses ( https://www.thingiverse.com/thing:1793515 ) with zero issues. In hindsight, I am guessing that this is due to the lower layer heights I used for that print. For printing of the enclosure parts, I wanted to print at large layer heights (0.25-0.3mm) at relatively hot PLA temps (215-220C) because I knew I would be running near the volumetric limit of the E3D V6. For printing, I attempted to use both the 0.3mm draft and 0.2mm speed settings, but both have had similar failures to what I have shown in the pictures.

I have tried troubleshooting in a number of ways:

- Cleared the nozzle with the acupuncture needle. Needle when in clean, I felt no resistance. No difference

- Tried lowering max volumetric print speed. No difference

- Tried upping and lowering printing temperature in the range of 205-225C. No difference

- Swapped nozzles to a 0.4mm E3D hardened steel nozzle. No difference

- Swapped to a different spool of filament (Inland white PLA -> Inland white PLA), no difference

- Swapped to a different brand of filament (Inland white PLA -> Paramount 3D PLA), no difference

- Bypassed MMU buffer and fed filament directly into MMU unit to bypass the small amount of friction in the buffer system. No difference

- Varied the tightness of the idler screw. I loosened it quite a bit, and I believe having it too loose led to the lack of extrusion in photo 3. Tightening to 1-2mm below the surface made no difference

Is there anything else I should try to troubleshoot? I have tried pretty much everything I could think to try. My prints are still on the bed, so I can take additional photos if need be, and I am running firmware 3.8.1-2869, repo prusa3d/Mk3. As I am typing this, I am just now realizing that it says Mk3, not Mk3S. Would a difference between Mk3 and Mk3S firmware possibly cause this issue? If not, my next guess might be heat creep past the heat break, but other than that, I don't really have any idea. Thoughts?

Best Answer by Hypersonic:

Final update: The slight misalignment of the extruder drive gear was the cause. In case anyone else encounters problems like this, make sure that your extruder driver gear is aligned as perfectly as you can get it. As a guide, I looked to see a sliver of the teeth on the gear on each side of a piece of filament that I put into the extruder path during alignment. I will also mark this comment as an answer for future readers.

Now onto trying to get my MMU2S working...

RE: Intermittent Under-extrusion During Large Layer Heights

Update: It seems as though my filament extruder drive gear was about 0.5mm off-center. I believe that made the extruder gears periodically lose grip on the filament. I am currently retrying the above print with an adjusted extruder gear and also 0.4mm less retraction which was the fix I was going to try before I noticed my extruder gear was not quite in line with the filament path.

RE: Intermittent Under-extrusion During Large Layer Heights

Final update: The slight misalignment of the extruder drive gear was the cause. In case anyone else encounters problems like this, make sure that your extruder driver gear is aligned as perfectly as you can get it. As a guide, I looked to see a sliver of the teeth on the gear on each side of a piece of filament that I put into the extruder path during alignment. I will also mark this comment as an answer for future readers.

Now onto trying to get my MMU2S working...