Interesting facts about bearing lubrication from the horses mouth

the lubrication of bearings like these is not a simple this is the best way question as it comes down to the application and environment in which the bearing must work. you might find this of interest. http://www.nsk.com.br/upload/file/e3317.pdf

take a look at this PDF as it relates to the bearings we use on our printers

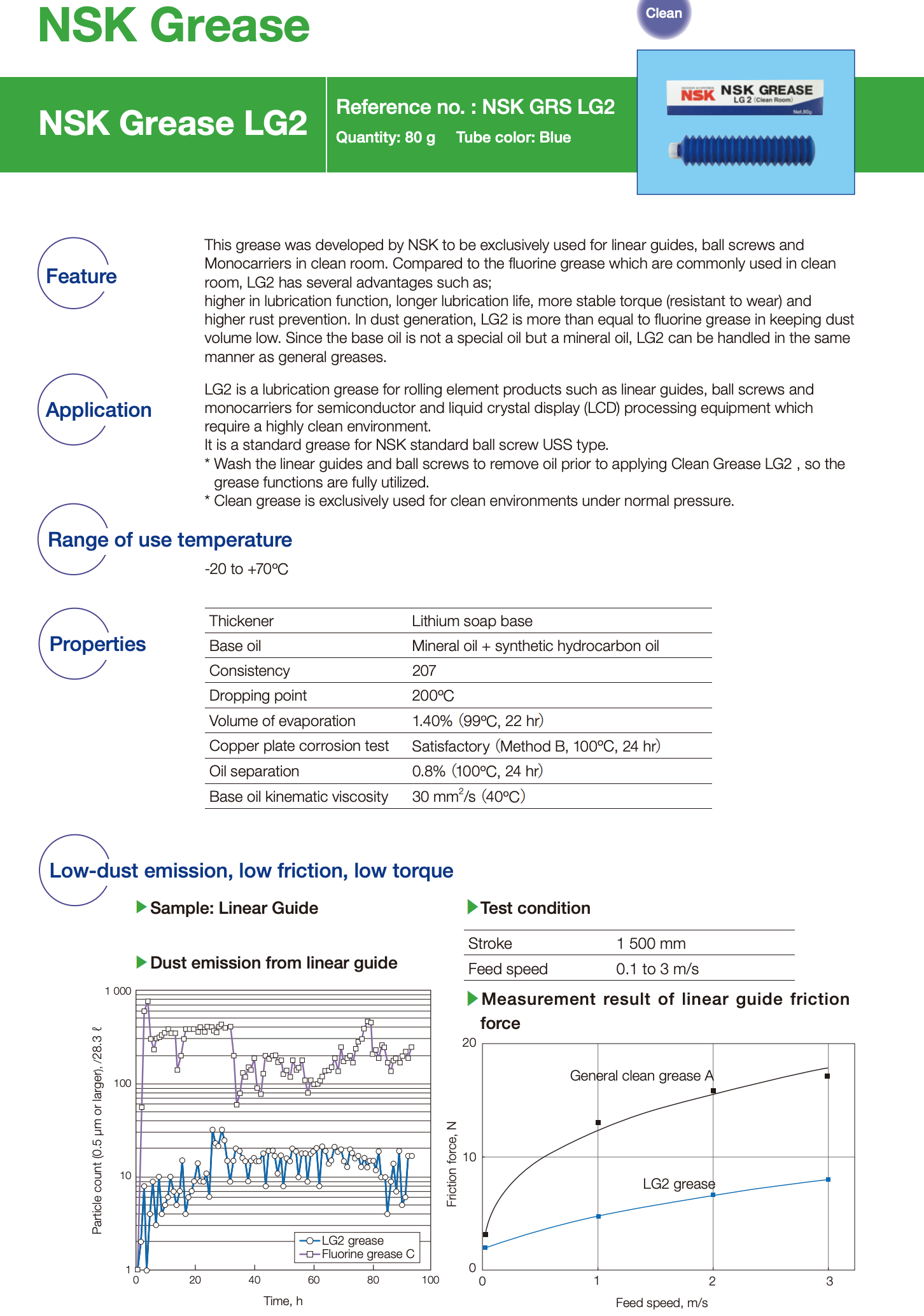

this is a key page from the PDF above in the URL This is what I will use when upgrade to matched Misumi bearings and rods.

Re: Interesting facts about bearing lubrication from the horses mouth

if I'm converting correctly, that stuff looks like it is many times more viscous than common light oils or ptfe we have been using. I don't even know what to believe anymore, except my printer has never run better since using ptfe on misumi lmu8 🙁

obviously we're not using these in super high load or clean room environments like the pdf mentions, but still

Re: Interesting facts about bearing lubrication from the horses mouth

I am told that if you buy your bearings and rods through Misumi, you have the option to get them pre-lubricated. They use NSK-LG2 so perhaps that one would be a better match ... it is fresh news to me and here is that page from the PDF it is a bit cheaper than the LGU I settled on as the LGU is food safe hich I expect requires a longer paper trail in industrial use.

Re: Interesting facts about bearing lubrication from the horses mouth

Nice advertising 😉

But in generally : correct

Thomas

Re: Interesting facts about bearing lubrication from the horses mouth

Nice advertising 😉

But in generally : correct

Thomas

I guess I should state that I am neither a lubrication engineer nor do I have any connection with NSK other than as a user of their bearings over the last 50 years... mostly over the last 20 as Timken bearings have reduced their bearing range of stock designs and sizes requiring special order for older designs... NSK has a longer list of these sort in stock and with the antique restoration I do.

I have increased my use of their product.... but I am not a shill for their products and I feel that dissemination of manufacturer product data such as can be seen in this PDF is of value to those who want to understand how their hobby machines work and how best to care for them.

Do let me know if the posting of informational PDF links of this sort is not desired here. I understand that this Forum Belongs to Prusa and that marketing products that they sell would not be allowed but I don't recall seeing bearing lube for sale in their eStore.

Re: Interesting facts about bearing lubrication from the horses mouth

Hi.

Thanks for the research and sharing your experiences.

What itches me is that these lubricants are specified for clean room application and emphasizing their low dust emissions (which is a yay for clean rooms). Sorryly it says nothing about their capacity for collecting dust. My shot at this is, since these are highly viscous, they havve a low surface tension and thus tend to absorb dust. which should quickly degrade their properties if used in a non-clean-room (thus dusty) environtment. And I dare to say most of us are living in a dusty environment with between 500.000 particles per cubic meter for inner cities and 10.000 praticles per cubic meter at the north pole. I guess the folks developing such lubricants have clean rooms according to the highest class in ISO 14644-1 in mind, with around 35 particles per cubic meter, an overpressured laminar flow air conditioning and monstrous filter systems.

Besides: operating our printers would surely not be compatible with clean room standards, because, honestly, they are spraying microparticles all around.

I need to do further research, but my stomach tells me PTFE is enough.

I'd appreciate other opinions and further hints concerning lubricants.

Regards,

Achim

-Prusa i3 MK3 single extruder (kit) as intended by author

-Creality CR-10 modded beyond recognizabilitty 😀 Constantly sleep-deprived. General wisecrack of the benign kind. Knows he knows nothing.

Re: Interesting facts about bearing lubrication from the horses mouth

well I wipe down the rods each day and that collects the last 24 hours of dust etc that has accumulated and I toss a dust cloth over them when not in use... but I do take your point...

however you should see my home machine shop where the daily wipe down paper towels are very dirty after use. my tools have lightweight Spindle oil, added fresh each day they are run, to their high speed parts and sticky way oil for sliding parts also renewed daily... Then we have various cutting oils, microdrop mist cooling fluids and tapping fluids as well as quite a few others in use. even a home machine shop is not a clean place, most of my machines are over 50 years old and had decades of industrial use before I obtained them. In some cases when I got them I rebuilt them 15 to 30 years ago. They are as accurate today as they were when new...

Some to a ±0.001 inch standard and some to ±0.00005 inch standard and one (the surface grinder) that can work to ±0.00001 inch if I do my part on these latter type and control the temperature of the part being made.

Now modern machines do use recirculating lubrication and filter it (and modern in this context can have several meanings as heavy machine tools have done this for about 100 years and by 50 years ago they had replaced total loss lubrication on even machines not much larger than my Bridgeport

the point of all that is that daily maintenance has far more to do with the life of machines holding their as built tolerances and I think that is also true of our printers... to have contaminated lubrication getting back past the seals on our bearings and acting as a "grinding paste" is not much of a concern for me first of all other than in the "grinding room" area of my shop the dust found in most homes is not very hard being mostly dead skin cells and pet dander etc and remember that the bearings and rods on our machines are hardened

Re: Interesting facts about bearing lubrication from the horses mouth

Wohaa, that's some home shop! I know only one man with a Bridgeport in his cave. I'm far beneath that level.

Yet I'm with you on the point of "love your machines and they love you back".

Anyway, my machines feel loved enough with a less expensive PTFE lube and I don't feel I need to do more to preserve their 0.2mm tolerance. There are too many other things that have a stronger effect there. And since I'm a hobbyist who generates no income with his machines, I have to take economics into account. The cheapest is seldom the best, but there's a threshold above which a further improvement takes exponential effort. So I stick below.

And, forgive me, I have to quote here (and I totally mean it as a compliment):

"Do not meddle in the affairs of wizards, for they are subtle and quick to anger." 😀

Cheers!

-Prusa i3 MK3 single extruder (kit) as intended by author

-Creality CR-10 modded beyond recognizabilitty 😀 Constantly sleep-deprived. General wisecrack of the benign kind. Knows he knows nothing.