Inconsistent first layer based on X-axis direction

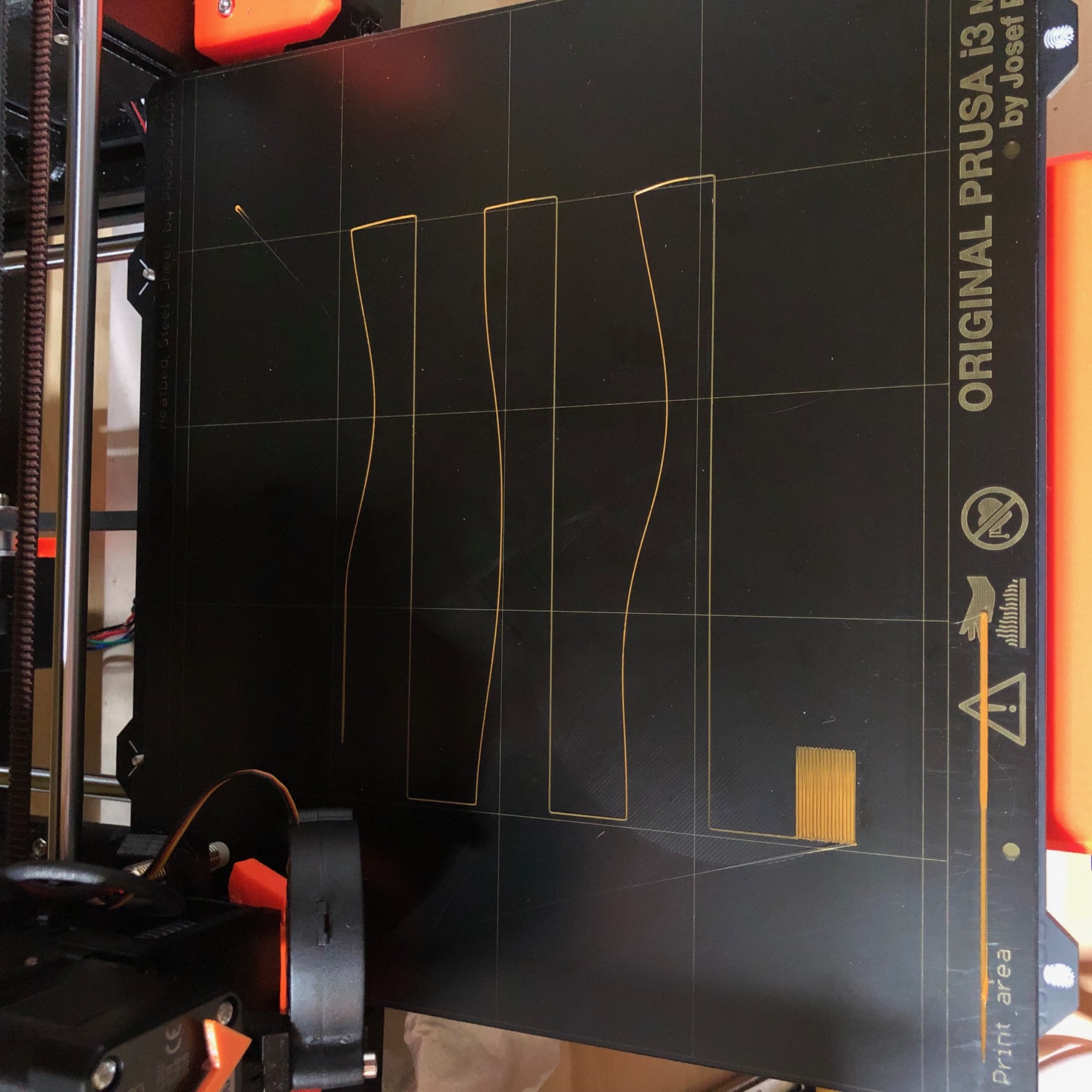

As you can see in the attached photo, I'm having inconsistent first layer extrusion and/or adhesion, based on which direction the X-axis is moving. If it's from left-to-right (X+), I get very bad adhesion, and if right-to-left (X-), the filament is properly squashed. In the photo, I dragged my finger lightly over the extrusions, so you can see which ones easily moved and which remained stuck to the bed. This has cropped up on my Mk3 just recently (after a good amount of recent printing), and I'm not sure what's causing it.

When I first looked at the problem, it seemed to me that the heater block and nozzle were able to slightly wiggle — perhaps some incorrect tightening when I installed the ruby nozzle? I tightened that down, and it seemed solid again, so I re-printed the first layer calibration test, but the same results persisted.

I then tightened all of the screws on the X-carriage. Same results.

I'm at a loss now. What else can I check?

Thanks,

Mark

Re: Inconsistent first layer based on X-axis direction

Addendum: based on further observation, I don't think this effect is limited to the first layer, but is continuing throughout the print. (It was hard to tell at first, since the prints weren't sticking to the bed.)

Re: Inconsistent first layer based on X-axis direction

Your live Z is still too high. The postage stamp at the end should be one solid piece, with no gaps in the lines. A very common issue.

See the Life-Z adjust thread in the Assembly and first prints troubleshooting sub forum for more info. I just posted in that forum with a post that has a larger example STL 75X75 which is easier to see to set the first layer if you desire.

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

Re: Inconsistent first layer based on X-axis direction

Thanks, but that’s not the problem. The problem is the height of the layer is different depending on which direction the X-carriage is moving.

The “postage stamp” at the end is one solid piece, with no gaps in the lines. The thing is, the lines going one way are just lightly adhered, and the lines going the other way are printed so close to the bed that it looks like almost nothing at all.

I hope not to offend, but I've been working with RepRap printers for 8 years, so I'm fairly certain I know what I'm talking about. I just haven't seen this particular problem before.

Re: Inconsistent first layer based on X-axis direction

meet half way

lower the extruder by increasing the negative live Z value, and see it your varying thickness strips stick better. and if they do, then investigate the variation in thickness next

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Inconsistent first layer based on X-axis direction

lower the extruder by increasing the negative live Z value, and see it your varying thickness strips stick better. and if they do, then investigate the variation in thickness next

Thanks, Joan. I guess I didn't mention in my first post, but that's already been done, which is why I'm investigating the variance now.

Please see my previous post (which I guess I was editing while you replied) for more details.

Re: Inconsistent first layer based on X-axis direction

ok Bobtiki,

you have at least two issues,

1, some filament is not sticking to the build plate,

2, the filament that is sticking to the build plate is not squishing together enough in the postage stamp area and it's probably not squished well in other areas either

both of these issues can be addressed by lowering live Z. going more negative

you also say that the filament layed in one direction, is thinner than the filament layed in the opposite direction...

this may be true or may be an optical illusion caused by the displaced filament appearing brighter than the bonded filament... the bonded filament looks darker

if you look at the postage stamp area, which also has filament layed down in both directions, the two directions look similar thicknesses

you ask for help and then reject the help offered. there is not a lot more we can do from afar!

our suggestions address the one common problem that we can see,

after that, we may be able to see other issues

kind regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Inconsistent first layer based on X-axis direction

I'm not rejecting your help — I'm just saying that what you think you're seeing is not what you're seeing. 🙂

If I lower the Z-height enough so that the X+ direction is sticking to the bed, the X- direction so low that it's dragging through the printed PLA, and smearing it into almost nothing. Very much like what you see there — the parts that look like gaps are not gaps, but where the nozzle scraped through the previously laid-down plastic.

There is no middle ground. Either the X+ direction doesn't stick and X- sticks correctly, or X+ sticks correctly, and X- is within microns of the bed, dragging through the plastic already laid down. The difference between the two heights is too great for there to be a middle ground that works for both.

Again, not to offend, or reject your advice. I had the Z-level calibrated just fine before whatever causes this wiggle started happening. I do know how to calibrate the Z-level. I do not know what's now causing this variance.

Re: Inconsistent first layer based on X-axis direction

are you aware that the ruby nozzle has a shorter screw thread than the E3d nozzle. if the hex nut is tight against the heatblock and the base of the nozzle is not tight against the heatbreak tube, then the ruby nozzle inner sleeve may not be fully locking the ruby insert in place, allowing it to shift, which may cause your variations in thickness, and may eventually lead to leakage between the heatbreak and the nozzle,

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Inconsistent first layer based on X-axis direction

That I was not aware of, thank you. Will investigate.

Re: Inconsistent first layer based on X-axis direction

the pictures in this link

https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/having-issues-with-olsson-ruby-read-this--t26235.html#p122723

show the brass components of the nozzel for information sake

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Inconsistent first layer based on X-axis direction

Check Z lead screw flange nuts are tight to the X carriage ends, and that both Z motors are fully secured. If there is play, the torque from the X motor will be tilting the X carriage up and down differently based on X direction.

Re: Inconsistent first layer based on X-axis direction

Thanks, all. After a lot of checking and double-checking, and a few emails back and forth with Prusa support, I think we've found the problem — somehow my heat break had become ever-so-slightly bent. Perhaps while I was printing that wood-fill piece? I wasn't near the printer at the time of failure, though, so I'm not exactly sure how it might have happened.

I ordered a new heat break, and installed it today. Z-height adjustment now looks fine, and I'm presently printing a few parts in PLA. First layer looks good so far. Fingers crossed!

Re: Inconsistent first layer based on X-axis direction

excellent!

Glad you found the cure.

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Inconsistent first layer based on X-axis direction

Micro update: That must have been the problem, because since I replaced the heat break, the printer has been very reliable and the layers are all even. Thanks again for the help!

RE: Inconsistent first layer based on X-axis direction

You just saved my sanity. Was troubleshooting this for days. Thank you!