improving the height setting adjustability of the PINDA

Since Prusa is sending me a replacement PINDA to replace my deteriorating unit I have been thinking about making its installation and adjustment a bit easier.

As I have the needed 8mm taps I was thinking of tapping the plastic PINDA holder on the extruder carriage while the holding screw is adjusted up against a rod turned to the tapping size for 8mm 1mm pitch and jamming a pair of 8mm thin nuts against each other on the pinda (I will have to make these down in the shop as i only have M8 1.25 mm pitch standard nuts but I have some 8mm hex brass rod so making a pair of thin nuts is not a major task in the lathe)... a few mm from the end. then the lock screw could be loosened and the jammed thin nuts precisely turned knowing the 8mm pitch is 1 mm one full turn will move the PINDA 1 mm Half a turn .5 mm a quarter turn .25 mm etc . too bad the Pinda does not have a finer pitched thread... (looking at my metric taps and dies I see .60 mm pitch in 8mm but an even finer pitched rack could be provided on a an adjusting sleeve but that may not be a practical use of time or resources...

Since some form of better fine adjustment of the Pinda would be a good thing. I hope and expect smarter folk than I have considered better options than these, but my search skills are not up to the search here. I thought it best to check for the wisdom of the forum before I set off to do something dumb again.

Re: improving the height setting adjustability of the PINDA

I swear my pinda kinda self tapped itself into it's holder. I just turn it slightly with the screw loosened abit. dealing with the spinning wire is abit odd at first but not too bad.

I have a Prusa,therefore I research.

Re: improving the height setting adjustability of the PINDA

surely you will beed bigger stock, than 8mm hex, for a nut with an 8mm thread?

the early mk2, had nuts for adjustment, and it was fairly crap... the bracket was weak, and the nuts not easily adjustable, it would have been better with a combination of 8mm nuts, and pinch bolts on the plastic mounting sleeve.

the Mk3 doesn't have a lot of space for nuts to rotate on the top side of the extruder clamp...

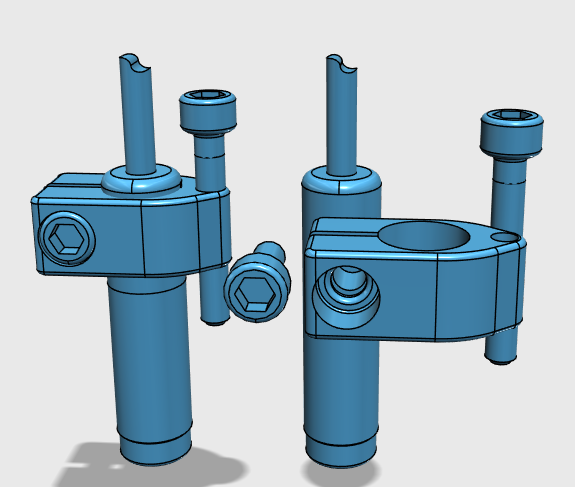

for the Mk3 you could make a metal clamp like below using 3mm hex cap head screws, from your spares bag, (the pinch screw will probably need shortening...) clamp it around the unthreaded section of the Pinda, at the top.

M3 screws have a 0.5mm pitch

the long hex screw could be used to raise the pinda within the existing pinch clamp on the extruder body

start with the pinda a bit low, so that you have safe clearance for the nozzle above the heatbed,

run liveZ adjust, see what the Live Z value is,

then with the pinda lightly clamped in the extruder housing, use the long screw on the new clamp, as a jack, against the extruder housing, you can raise the pinda a little, and retest live Z adjustment until you arrive at your preferred value... since the jack screw pitch is 0.5mm, half a turn will raise the Pinda 250 micron. (don't forget to readjust live Z by the same ammount. or you will damage your pei ) this will help reduce the guesswork

then tighten the pinch bolt on the extruder housing, to prevent the pinda moving after final adjustment

so, if your initial live Z was -1.250

you could adjust the jack screw one whole turn, and change the live adjust Z value in the settings menu to -0.75 and re test... if you're not feeling lucky, reset live adjust Z to 0 and re run the physical adjustment, and see if it now comes good at 0.750 mm

Hope this makes sense to you,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: improving the height setting adjustability of the PINDA

thanks Joan,

I miss spoke the hex brass stock I have is 12mm

I can see that your idea is better, it gets around the way the cable can get twisted and stressed if the whole pinda is being turned... I need to think on this a bit more But you have a Better solution that is clear.

Now to decide to make it out of metal down the shop or to use it as an exercise in learning Fusion 360 and print it out of petg, the 3mm threads won't get enough use to make it a problem (Their running in plastic).

Re: improving the height setting adjustability of the PINDA

Joan the more I think this the better I like your Idea and I have added it to the future projects pile... I do wonder how much the variation in the sensing reaction hight between different PINDAs is the root of the need for some modification like this (and that in part only a problem for me due to things like a glove size of XXXXL and numbness in my fingertips due to age and creeping PN) and if they get their act together and produce them with tighter tolerances there would be no need for this sort of thing and the Super PINDA™ will slot into the extruder of the day perfectly set up :geek:

if I ever do get around to doing this and getting it onto thingverse I will be sure to credit the idea to you.

Happy Christmas to you and yours and all the gang here from all over the world