Hotend - Are their any definitive fixes?

Hello, I want to love this printer, but from day one and my third hotend, it just is not reliable. I'm tired of cold pulls and unclogging and new nozzles etc. I'm sick of having to disassemble the entire extruder to change a nozzle because it become loose between the heat break and heater block. Then there is the random overextrusion and blobs everywhere.

I printed an entire Voron and about 12 stealthburners on my Ender and have not had a single clog or underextrusion/overextrusion blobs all over issue yet.

The cooling shroud is warped to hell after less than 9 months of printing as well and this has only printed ABS two times at 255 C.

Please help before I start shooting the extruder and hot end for target practice while using the x axis as a target holder.

my third hotend, it just is not reliable. I'm tired of cold pulls and unclogging and new nozzles etc. I'm sick of having to disassemble the entire extruder to change a nozzle because it become loose between the heat break and heater block. Then there is the random overextrusion and blobs everywhere.

These are all rare events for most users. The most common causes of your issues are misassembled hot-end/nozzle assemblies, see:

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

... pay particular attention to the diagrams at the bottom of the page, the placement of the gap is fundamental.

And filament quality. While poor filament is rare these days many long term printers have old, dodgy, stock from the early days.

Also the more precise printers are more susceptible to poorly stored filaments, damp filament is a particular problem for many users, especially this year.

Unless you are printing abrasive filaments you should only just be coming up to your first worn-nozzle change. What prompted you to change them?

Are you using an enclosure for ABS?

Cheerio,

RE: Hotend - Are their any definitive fixes?

I would say it's not too rare if their is the entire Issue 602 github on similar problems... I just don't want to have to start modifying a machine that should be under warranty.

As far as nozzle changes, if I get constant clogs after cold pulls and cleaning I switch the nozzle. My last 4 prints failed due to it having clogs and partial clogs so I just opt to switch it. No I have only printed PLA and PETG on this machine save two short ABS prints (as in 12 minutes, so I didn't worry about an enclosure). I don't trust PETG in an enclosure, the PC/ASA fan shroud is already deformed without having any extra heat.

I have never down a cold pull on any other of my 3d printers. I use the same filaments in both my Ender and Voron and have had zero issues. Not one clog on either ever and I've printed on the Ender for coming on 4 years. The only filaments I use are Polymaker, Hatchback, and Prusament.

RE: Hotend - Are their any definitive fixes?

Just rebuilt it again. New nozzle. Half way into the first layer (25 minutes) already starting to clog.... stock settings in Prusuck Slicer just to make sure I'm not messing it up... Prusament. I'm not sure what to say at this point. Seems this little 5v cooling fan is just not enough to keep the filament from getting sucked into the cooling section hot. Which is what the Github 602 page finds as the largest problem, not enough hot end cooling.

Prusa, what's your response when will you get a 24v fan like everyone else?

RE: Hotend - Are their any definitive fixes?

602 is something entirely different from what you describe. Maybe your heatbreak or PTFE tube are messed up. And you should not be getting nozzle loosening if the nozzle is tightened following the correct procedure.

FWIW, I have had my Prusa for about the same length of time as you have had yours, and I have never needed to do a cold pull or change a nozzle on it. I did see some deformation of the fan shroud, but only because I was removing that shroud to install a modified unit for unrelated reasons. It wasn't bad enough to have caused any problems or be noticed on its own yet.

RE: Hotend - Are their any definitive fixes?

Are you printing at extremely low layer heights? Or printing PETG at PLA temps? Or switching from PETG to PLA without heating back up to PETG temps before switching? Are you using an E3D or another quality nozzle?

It sounds like you have lots of experience so please don’t take offense, anything is possible. I’ve been printing with a MK3S+ for 18 months, primarily PETG and some PLA without ever experiencing a clog (yes, I consider myself very lucky).

I did buy a roll of cleaning filament and always run some through the hotend when changing over from one type of filament to another. I rarely need to do a cold pull. I’ve only changed the nozzle once and purchased a E3D nickel plated copper nozzle.

I rarely print layer heights less than 0.15mm. Lower layer heights generate more back pressure and increase the potential for clogs.

Hope you get it sorted.

Cheers

RE: Hotend - Are their any definitive fixes?

I had a problem with a non prusa fan changing the settings in the experimental menu, fixed that..

on intricate models you can hammer the filament into a larger pellet, using large retractions, which eventually clogs the hot end, so i use 0.4mm instead of the default 0.8mm retractions

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

With your printing history you should still be on your first nozzle - are you using genuine E3d parts? There are 'clone' nozzles commonly available that are a fraction too short in the thread causing no-end of problems.

Cheerio,

RE:

I wish I could say anything you guys suggested is an issue. These are nozzles and hotends directly from Prusa, so if it's not officially E3d... I'm not sure how to get one.

0.2mm layer height, sometimes 0.15mm. I almost always use PETG on this machine and it's not between changes this is mid print. Temperatures vary on filament manufacturer and color after I do a temp tower. some as low as 220C some as high as 245F. I printed ABS twice at 255. The shroud should not be deformed from that.

@NetPackRat - The 602 issue is very much like this, actually the same if you read the information. The filament is clogging, likely due to insufficient cooling as the filament is warming further into the heat break and softening. Then when you go to extrude again you get a pressure build up and overextrusion. Next retraction, it cools and you repeat. Eventually it clogs.

RE: Hotend - Are their any definitive fixes?

It was my understanding that 602 is a cosmetic defect caused by the way the hob gears in a direct drive extruder can induce a variation in filament speed based on how they grab the filament and the speed of the motor. Far less prevalent in bowden drive extruders like your Ender has.

Anyway, if you think the issue is cooling related you may be able to fit a higher output fan; the only issue with that is the firmware expects either the Noctua or Delta fans used by Prusa and it can cause problems with other fans. I am told there is an "altfan" option that can be selected through the LCD screen menu that will bypass Prusa's anti-noise BS and just run the fan at 100%. This is one of the differences between the Bear firmware for the Bear extruder and X axis and the Prusa firmware; it just runs the fan at 100% no matter what fan you use, and it's one of the reasons why the extruder in my Bear printer cools much better than the one in my Prusa. It's a little louder than the Prusa (I am using a Sunon in the Bear) but that's not something I care about.

RE:

Netpackrat, you should dig deeper on 602, its about the entire extruder/hotend sucking. I should also note the Ender is DD, linear rails, all metal hotend, dual z extended bed.... so no I don't deal with a bowden except to guide filament from the spool to the drive.

And 602 is a bit more than gear mesh issues hence why they modify the entire hot end to fix.... actually a lot more. And if you read my posts, you will see that I'm not keen on modifying a machine that is supposedly under warranty... I want Prusa to give me a fix... which will never happen.

And this is by far the noisiest printer I own, so I'm not really sure I need to make it louder, although a little 5v fan can't be louder than the steppers without silent drives.

As far as the Bear ideas: so you paid $1000 for a printer that is worth maybe $400 just to modify it to work because the manufacturer is still stuck in reprap days? And on that paid another $100 plus in parts to do so? Why not just buy a pre-built Voron or a Bambu for $100 more? Prusa is a multi-million dollar company. They need to start fixing their sh!t instead of touting it as the best on the market.

I'm still waiting for Prusa to respond as the fan shroud thing is a big deal. I shouldn't have hot end parts melting less than 9 months after the machine was bought. Yes I can print parts, but its like telling someone to buy a car and to machine their own parts because the original are crap. Oh, and melting plastic is kind of a fire hazard.

RE: Hotend - Are their any definitive fixes?

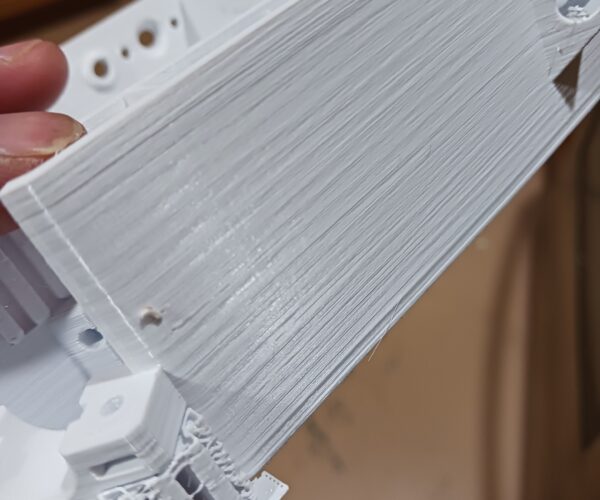

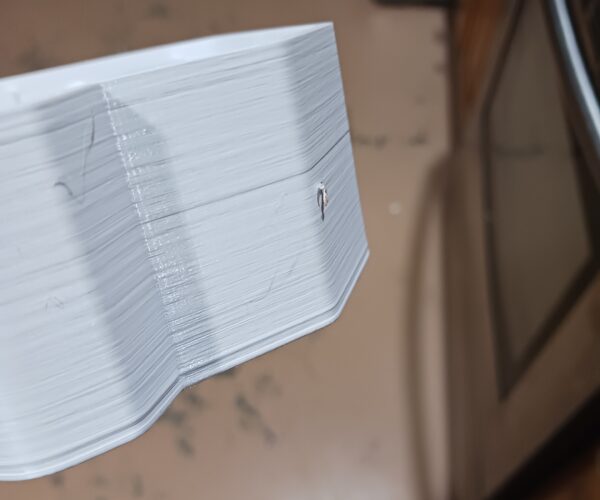

This is what an $1100 printer does stock..... not acceptable. These are their stock settings and their filament. I have my own settings that help, but its still bad.

RE:

Not that you probably care, but I bought the Prusa and I liked it, so I built the Bear from scratch (second printer). Currently using the Prusa to print parts for a Voron.

FWIW, Prusa doesn't pay a lot of attention to this forum so the only response you are going to get is just people trying to offer suggestions that might be helpful. Not sure why you feel the need to respond with condescension and snark to people who are only trying to help you. I agree that a newish printer that is under warranty should be printing better than that, and I would encourage you to contact Prusa directly rather than continuing to waste your time here.

Thank you for the pictures

Your hotend/nozzle is wrongly assembled; see the link I gave above, and your belt tensions are off (or possibly your smooth rods are dirty and need lubrication) attend to both then come back with a similar stock print, preferably in a mid colour, it's always hard to diagnose white.

Cheerio,

OK, so I took a look at the 602 page, ignore it.

Most of the first dozen or so pictures illustrating the problem show a mixture of damp filament and incorrect belt tension, if there is an underlying problem it's being masked by this.

Cheerio,

RE:

Diem, Wrong.

Belt tension is per Prusa specs, passes everytime although I agree its slack... its following their instructions.

As far as filament... way wrong my man. My filament sits in a house sub 30% humidity and I put it in the stove for 12 hours at 150F (right near the glass transition temp)

PacRat? What help has the forum provided so far? I've gotten only comments that are irrelevant or make no sense and honestly seem pretty fanboi with no actual meat or help.

Cheerio

RE: Hotend - Are their any definitive fixes?

Diem, the hotends came from Prusa. I think you need to read a bit deeper before you answer as this has been covered.

RE: Hotend - Are their any definitive fixes?

Diem, are you implying the stock Prusa software's belt tension wizard is off? When I tension it to Voron type specs I get a reading of like 150 which they say is way too tight.

RE: Hotend - Are their any definitive fixes?

For me the Hotend is also a nightmare. I lost interest in printing all together because of it. After only about 10 printed items the hottend is more glogged then running and now I cant even buy a replacement anymore. I love to build things but this is getting out of hand.

Hopefully at least I can buy a new hotend for my MK3S...