Help for clog removal saught

Hi community,

I'm having a bad clog somewhere inside the extruder of my MK3(converted-to-S). I think it's the "well known" PLA retraction, heat creep, 0.2mm step inside heat sink issue. Filament is still loaded and the bondtech gears have chipped quite a bit filament at that spot already. I'm unable to unload filament normally and pushing an acupuncture needle inside the nozzle doesn't get the filament flowing.

I've read all the Prusa documentation ( https://help.prusa3d.com/en/article/clogged-hotend_2008 ) of "cold pull", "forcing the clog out", etc. but I still have filament loaded. Those all apply to unloaded filament situation.

I then turned to the "filament stuck in the PTFE tube" section. Do I understand it correctly that I should remove the PTFE tube (with filament inside) while the nozzle ist heated? What happens with the partially molten filament from inside the heat sink/nozzle where the clog is? Won't this get pulled up and could contaminate/damage the inside of the bore where the PTFE tube was, so that I cannot insert the PTFE tube later on again?

Asking Prusa support to clarify this, I got the recommendation that I could also unscrew the nozzle while heated (still with filament inside?) and then do a quick "push, cut, pull" to get the clog outside the bottom and the rest of the filament upwards. But here I'm also wondering whether molten filament couldn't contaminate the threading inside the heater block when pushing out molten filament, so that as a consequence I'm unable to screw the nozzle back in?

I'm puzzled a bit. Please someone guide me what's the correct and best way to go forward with minimal negative consequences. If possible, I don't want to disassemble and replace everything!

Thanks and greetings,

Stefan

RE: Help for clog removal saught

I would start out by warming the thing up, maybe to 260-270 or so, and let it sit for a while, let the heat stabilize and move upward.

Then carefully, either manually or using the load function, try to get things moving.

You might also try probing upward with an acupuncture needle or small rod when the thing is hot.

RE: Help for clog removal saught

And I can't make things worse when "cooking" PLA inside the hotend? I remember YouTubers (Thomas Sanladerer?) saying so.

RE: Help for clog removal saught

If you're sure it's only PLA in there, you could try a lower temperature. I just pulled those numbers out of my head thinking of what higher temp filaments like PETg and ABS might need to soften. I think the key is to let it heat for a while and let the heat spread and loosen up anything that's in there.

RE: Help for clog removal saught

I wouldn't worry too much about cooking PLA if you're going to be cleaning it out quickly.

If you've got a jam somewhere below the Bondtech extruder gears, here's what I do:

- Raise Z so you can see what's going on.

- Remove the cooling fan shroud.

- Open the extruder door.

- Heat to 265C.

- Insert a 1.5mm x 150mm-ish rod down through the top of the extruder, past the Bondtech gears and into the PTFE tubing.

- Press firmly but not too hard, and avoid twisting the extruder assembly. With any luck, whatever's stuck will loosen and extrude out the nozzle.

- In some cases, you might need to remove the nozzle, clean the heater block out and insert your rod from below (holding it with pliers to avoid cooking your fingers).

This procedure has saved me many extruder tear-down and PTFE replacements.

A small hex wrench might be sufficient to push filament further into the PTFE tube, but usually not. I use brass rods from hobby shops, but @charles has found that 1.6mm tungsten welding rods work well.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Help for clog removal saught

Sadly I had to disassemble the hotend. This video helped a lot:

Removing the PTFE tube then showed that the tip of the filament indeed was larger than the inner diameter of the PTFE tube, so that there was no way getting it upwards. And I also realized why I wasn't able to push it downwards: the bondtech gears scraped into the filament in a way that it got flatter in one dimension, but larger in diameter in the other, so that essentially the filament did not fit the PTFE tube when pushing and did not fit when pulling either. 🙁

I've already ordered an original E3D V6 heatbreak (without the step), heatsink, nozzle, PTFE tube (OD 4, ID 2), silicon sock and Arctic MX-4.

I hope I have everything ready to replace those parts while maintaining the current heater block with thermistor and heater core with its cabling. I really don't want to replace the heater block and have to do all the cabling. 😮

Wish me luck ... or give me any final famous hints. 😉

RE: Help for clog removal saught

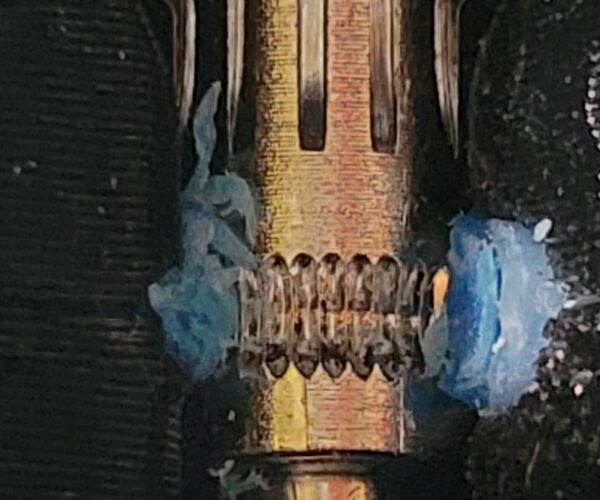

Did it look something like this? I had a print stop, no error message, but now the filament is well and truly stuck: I can't pull it out the top even.

This had happened previously with some wood-infused filament--which seems a bit brittle anyway--so I chalked it up to that. But this is good old pure PLA, and it did the same thing.

It is nearly 40 (101F) today, so I'm wondering if that was the issue? But it looks more like it was ripped up than melted.

RE: Help for clog removal saught

Woah! No, that's not what I have been seeing!

As I didn't take good photos (my cellphone's camera isn't that good in macro conditions) I just had to google for an example. It looked something like the second photo here: https://imgur.com/gallery/WIkNJkJ (not my photo, not my account) however still inserted and the chewed part exaclty located at the bondtech gears.

The "flattening" here was the reason I couldn't push it downwards into the PTFE tube and the clog inside the heatbreak was the reason I couldn't pull it upwards.

Still waiting for my E3D replacements to arrive (hopefully tomorrow or the day after) ...

RE: Help for clog removal saught

@stefan-b20

Thanks! I couldn't quite tell from the description. I'll post my question top-level.

RE: Help for clog removal saught

I just wanted to report back that I successfully repaired my MK3S with a stock vanilla E3D heatbreak - and installed a silicon sock.

Time will tell whether this "upgrade" got rid of the constant clogging when printing long PLA prints.