Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

At first I thought it's a clog after the 0.25mm nozzle stops extruding and clicking is heard. But then I did a cold pull and saw this:

How can I fix this without disassembly? Can I just get a nozzle cleaner and clean the possible plastic build up from the heat creeping up there?

I'm a newbie and dissembling means 99% chance of breaking something and killing my Mk3, and I'm not confident with my skills. So I want to avoid that.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

1st question: are you printing in an enclosure or with high ambient temps?

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

@bobstro

Thanks for replying. No enclosure and ambient temps of 23-25

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

@tim-m30

How is this fixed?

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

I'm hoping Bob can give an answer ... lol ... I sent him my heat break that was causing my jams.

Seriously, I replace my Prusa heat break with a stock E3D-V6 version and the jams stopped. The Prusa version has a 2.20 mm section that when things add up, it jams. Some jam some don't, and no one seems to have a good answer as to why. It might be as simple as a very minor difference in assembly - where the nozzle is a bit lower in the heater block, or the nozzle is a bit higher in the heater block. Even the heat sink paste used on the threads of the heat break/heat sink interface is in question.

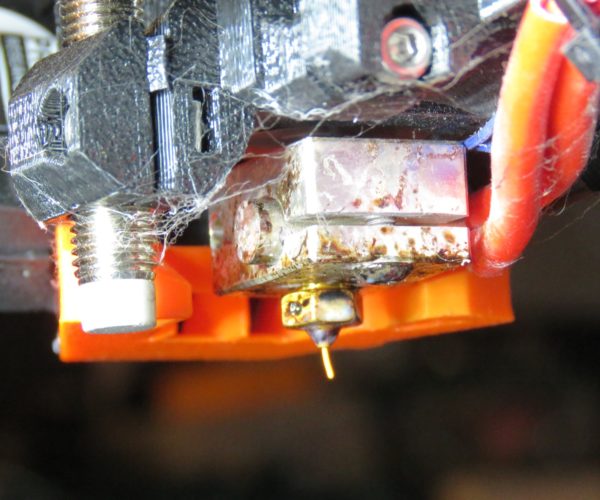

Take a good close up photo of the nozzle and heater block: try to show the nozzle best you can - similar to this photo: the gap between the nozzle hex and the heater block is what I am trying to see.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

I'm hoping Bob can give an answer ... lol ... I sent him my heat break that was causing my jams.

Got sidetracked with the stripped heater block last week, and I needed to observe it this week to ensure everything is back to normal. I've got a spare heater block and am hoping to play with your cursed heatbreak next week sometime. Not sure I'll have the patience to do a lot of long prints with it, but at least I can try a few things.

I think this is going to be one of those things that is highly dependent on a number of factors. Replacing the heatbreak is an easy-enough answer (though in my case, the heatbreak was welded to the heater block, the heater block was welded to the thermistor and heat cartridge - dem bonez!) but I want to play around with retraction settings. I've never been able to convince anybody experiencing the issue to reduce de-retraction speeds (I'm using 50mm/s retract, 25mm/s de-retract) to see if the non-Newtonian behavior of molten filament might come into play. I have seen a couple of threads where it seems the builder may have applied thermal paste between the heatbreak and heater block. There's a fair amount of variation in how far you can sink the heatbreak into the block as well. Any of these and other factors might be just enough to move the transition zone up enough to make a difference.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

Tim have you got a family of spiders living in your printer 🙂

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

Can a specific filament be the issue?

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

Guys I've been using the Silver filament that comes with the MK3 printer, but it's not prusament.

I just changed to a local brand which is black and it's printing an hour in, could it be the filament???

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

Guys I've been using the Silver filament that comes with the MK3 printer, but it's not prusament.

I just changed to a local brand which is black and it's printing an hour in, could it be the filament???

The non-Prusament that ships with the printer is decent stuff. A specific filament might have different behaviors with different settings and environmental issues.

You definitely want to determine whether it's a lower extruder or higher extruder issue. Not that they can't compound each other, but the fixes vary. "Heat" is always a concern, and air circulation is a big part of that.

A quick test is to try printing PETG. If that prints well, it's not purely a mechanical issue. If nothing else, try dialing speeds back with the front knob (50%) when the problem starts and see if that helps. If so, slicer settings may be all you need.

Do keep in mind that a 0.25mm nozzle will be more prone to blockages in general. Get good at doing cold pulls. I strongly recommended cleaning filament.

Was your printer a kit or pre-built?

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

with such a small nozzle diameter i wonder if you are hitting a volumetric extrusion limit with maybe the extruder too tight so filament jams before you‘d be warned by extruder noise?

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

with such a small nozzle diameter i wonder if you are hitting a volumetric extrusion limit with maybe the extruder too tight so filament jams before you‘d be warned by extruder noise?

Doubtful it is that. The E3D-V6 can melt more than enough plastic to keep up with anything a 0.25 mm nozzle can demand.

As for filament type? If you are trying to print ANYTHING with a metallic sheen a 0.25 mm nozzle is going to present problems. Galaxy Black, Mystic Brown, even the purple Prusament, all have flakes in them that I'd think can cause problems. I recall I had issues with Mystic Brown printing thin layers with a 0.4 mm nozzle; not full on jams, but layer inconsistencies. You might want to find a plain monotone filament to try.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

«tim-m30 there is volumetric limitation - just not caused by the heat blocks melting capabilities but by the nozzle diameter. If you feed too fast you will hit that limit. if your extruder does not start grinding the filament in time (reducing pressure) a possible scenario is that you get molten filament pressed back in the heartbreak.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

«tim-m30 there is volumetric limitation - just not caused by the heat blocks melting capabilities but by the nozzle diameter. If you feed too fast you will hit that limit. if your extruder does not start grinding the filament in time (reducing pressure) a possible scenario is that you get molten filament pressed back in the heartbreak.

I need to update my notes on testing throughput. I did finally try larger nozzles and the maximum throughput does increase, presumably due to reduced back pressure. I haven't tested with smaller nozzles. I suspect the max volumetric rate varies proportionally to the area of the nozzle opening. Which will really screw up calculating maximum volumetric rates in slicer settings. I got so far as being comfortable with 11.5mm^3/s as a safe default for PLA with a 0.40mm nozzle. Casual testing didn't indicate nozzle materials made much of a difference, which makes sense if they do ultimately hit the same temps.

For now, slowing way down in a good test.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

«tim-m30 there is volumetric limitation - just not caused by the heat blocks melting capabilities but by the nozzle diameter. If you feed too fast you will hit that limit. if your extruder does not start grinding the filament in time (reducing pressure) a possible scenario is that you get molten filament pressed back in the heartbreak.

I need to update my notes on testing throughput. I did finally try larger nozzles and the maximum throughput does increase, presumably due to reduced back pressure. I haven't tested with smaller nozzles. I suspect the max volumetric rate varies proportionally to the area of the nozzle opening. Which will really screw up calculating maximum volumetric rates in slicer settings. I got so far as being comfortable with 11.5mm^3/s as a safe default for PLA with a 0.40mm nozzle. Casual testing didn't indicate nozzle materials made much of a difference, which makes sense if they do ultimately hit the same temps.

For now, slowing way down in a good test.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

«tim-m30 there is volumetric limitation - just not caused by the heat blocks melting capabilities but by the nozzle diameter. If you feed too fast you will hit that limit. if your extruder does not start grinding the filament in time (reducing pressure) a possible scenario is that you get molten filament pressed back in the heartbreak.

I need to update my notes on testing throughput. I did finally try larger nozzles and the maximum throughput does increase, presumably due to reduced back pressure. I haven't tested with smaller nozzles. I suspect the max volumetric rate varies proportionally to the area of the nozzle opening. Which will really screw up calculating maximum volumetric rates in slicer settings. I got so far as being comfortable with 11.5mm^3/s as a safe default for PLA with a 0.40mm nozzle. Casual testing didn't indicate nozzle materials made much of a difference, which makes sense if they do ultimately hit the same temps.

For now, slowing way down in a good test.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

«tim-m30 there is volumetric limitation - just not caused by the heat blocks melting capabilities but by the nozzle diameter. If you feed too fast you will hit that limit. if your extruder does not start grinding the filament in time (reducing pressure) a possible scenario is that you get molten filament pressed back in the heartbreak.

This "overflow" effect happens even with retractions and a 0.4 mm nozzle; so it probably also happens with a 0.25 nozzle. But my thought is it's retractions that make it happen, not so much the actually pressure doing the forcing. Though this segment of Polycarb that has extruded a nice long fragment up into the heat break hints it could also be pressure exerted during long higher volume flows.

ps: in any case, the OP filament imaged above shows no sign of any dramatic backpressure forced upwards extrusion like the PC example here.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

I would have interpreted the OPs image differently - bulge on the right side of the image is in my opinion partially heated material fused to the filament strand.

Looking on the OP filament image and the short color transition zone from mottled grey to more substantial black before the stretch zone i wonder if there is some kind of heat (the lack of..) issue involved. Might be just the light on the image.

RE: Heat Creep issue suspected with 0.25mm nozzle printing on my Mk3

I got so far as being comfortable with 11.5mm^3/s as a safe default for PLA with a 0.40mm nozzle. Casual testing didn't indicate nozzle materials made much of a difference, which makes sense if they do ultimately hit the same temps.

For now, slowing way down in a good test.

I've been playing around with PLA (made an error and ordered some spools of black PLA instead of PETG so I have plenty test material to waste) and volumetric speeds to evaluate a safe max for my printer as well. Up until now I had great success with setting 14mm³ on the 0.4 nozzle. I wonder if Slicer calculates correctly.