Filament stuck in the hot end?!

Hi guys!

Another problem after another haha Built my mk3 recently and it's been working fantastic the past 2 weeks until last weekend. Had a splat of printing a job and it clogged up the nozzle area but I was able to clear it up via heating it up, swearing and carefully picking around the cables. It worked fine for another 2 days until this fine weekend. Smells like something died/burned/melted, so I started the process of unloading the filament. And at the end, I had to yank out (with alot of struggle/heating/MUCH patience) what PLA filament out of my extruder. BUT I was able to figure that something still seemed stuck in the hot end area when my extruder wasn't even "loading/letting out" any filament. Is this normal and does it happen often? 😐

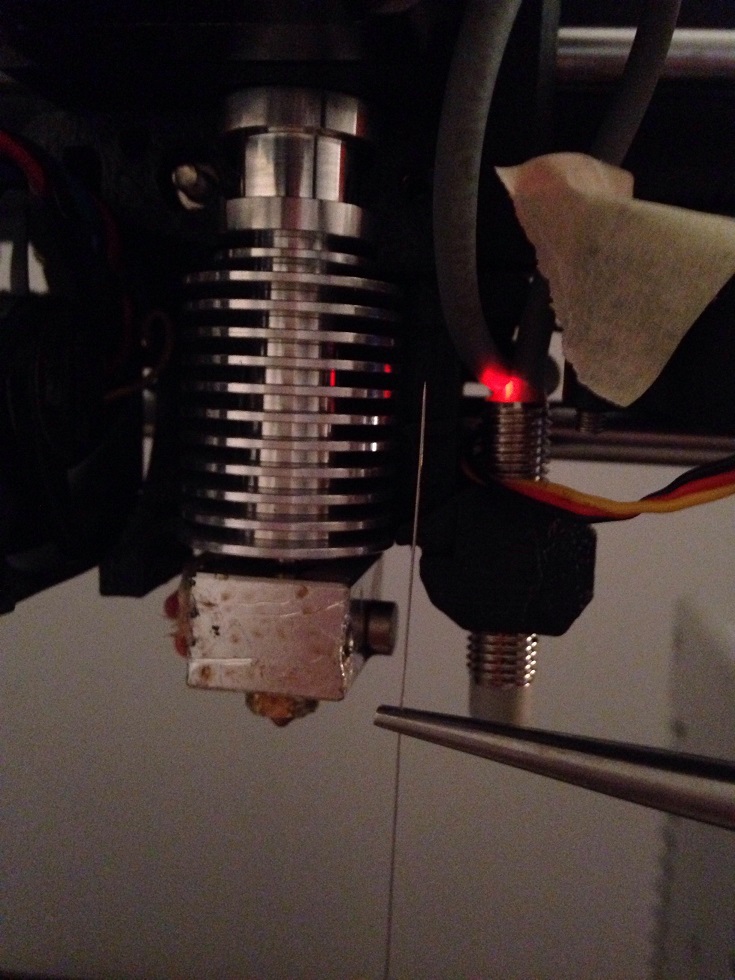

I've followed the "replacing nozzle" instructions in the manual/booklet to dissemble the extruder for visible inspection. And here's a photo of how far I was able to test a needle going in from bottom up the nozzle before feeling it getting stuck around the mid area with the multiple lined cylinder (Obviously a techhead who knows the language...) = so around 3cm upwards.

I've heated this up to 250/270 degrees (and waited 5mins to see if it'll melt like cheese) and poked/prodded it to try unblock it. But it keeps bending the needles (0.3 acupuncture ones, yes. I went to buy some ruddy acupuncture ones like the booklet said.) I have and remain clogged.

Just wondering if there's anything else I can do to figure out what is this evil? Or if it's at the point where I'll have to consider getting a replacement part? OR is this how it's supposed to be and I've been trying to fix the wrong part!?

Hope to hear from you soon.

Cheers,

Christie

Re: Filament stuck in the hot end?!

Since your needle is getting past the nozzle and up partially into the hotend, a partial blockage sounds likely. Open up the extruder housing (2 screws on left) and examine the feeder gear area. There's a bit of PTFE tube below the gears through which filament is pushed into the hotend. Do you see anything poking up? It's not uncommon for filament to break off in there, particularly if you've had to fight to pull it out in the past. If filament breaks off below the feeder gears (where the gears can push it into the hotend) but above the hotend (where it would melt), you can remove it fairly easily. To check for a blockage:

1. Loosen extruder tension gears at left of extruder housing.

2. Examine PTFE tube below feeder gears for stuck filament. Try to pull out if reachable with needle-nose pliers. Is successful, stop here and try reloading.

3. Raise Z to max for clear view.

4. Remove the orange part cooling fan via the single front screw.

5. Head nozzle to 250C to loosen everything up.

6. Remove nozzle by grasping heatblock with 17mm wrench or pliers. You want to prevent the block from rotating and damaging the heatbreak.

7. Remove the nozzle using a 7mm socket. Ideally, you want a socket that will hold the hot nozzle. Be careful with it, and have a place to put it to cool.

8. Use a length of wire to fish out any gunk from the nozzle socket in the heat block.

9. Use a 1.5mm rod, wire or wrench to push up into the heat block from below. You want to gently probe upwards until you can insert it up into the PTFE tube from below.

10. Examine the feeder gears and PTFE tube. With any luck, a bit of stuck filament will be poking up.

Reverse the process to reassemble, remember this thing is still HOT.

If you have a spare nozzle, you might try it just to eliminate a partially clogged nozzle from the equation.

What firmware are you running? Recent firmware updates addressed extruder motor overheating which could weaken filament above the hotend.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Filament stuck in the hot end?!

Sounds to me like the OP may have melted filament *before* the heatbreak, probably from a retraction or an unloading. Because of this, you can't melt it out. That happened to me recently. The fix is to remove the heatbreak and clean it out.

Re: Filament stuck in the hot end?!

I have had good luck with heating up the hot end, opening the bond tech tensioner, and sliding a very small ball allen down in to the ptfe tube to clear blockage. This has happened to me a couple times when I have let the filament run out.

Re: Filament stuck in the hot end?!

Currently in the same boat. I've tried all the normal unclog tricks as above, and expect to have to take apart the hot end assembly to clean it out. Fortunately, I have my original to "practice" on before working on the replacement that's currently installed. My current conundrum is how to remove the clip that holds the PTFE tube in the heat sink? I don't want to brute force it, because I'd rather not break it if that can be avoided. I have not been able to find a guide on how to remove it. Any help on that would be appreciated, along with any other tips for clearing a hard clog above the nozzle like this.

I haven't done much more than probe with a needle through the nozzle, and then a small drill bit with the nozzle off. I won't be surprised to find that I've mangled the PTFE tube, but I decided I'd better do more research on the proper methods before ruining more things.. like I did the last time I tried to solve a problem on my own. LULZ

TIA!

Re: Filament stuck in the hot end?!

Hi Mr flippant.

The black ring is only removeablewhen the ptfe is out.

Sometimes it is easier to undo the heatbreak and push the ptfe out of the bottom of the heatsink.

If the top of the ptfe is a bit mashed. Consider cutting it off at the top of the black ring to make it easier to push through

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Filament stuck in the hot end?!

Exactly the answer I needed, if not the one I wanted. 😉 Looks like complete disassembly of the hot end is what I'll be doing.

Thanks, Joan!

Re: Filament stuck in the hot end?!

Hi guys!

Just wanted to let you know to conclude this thread: it was the teflon tube. No idea how since this is less than a month since I built my printer, but the tube was pretty warped and wouldn't let anything through right in the middle (I must be cursed haha). Got a replacement thanks to Voxelfactory and put it back to together and it's working fine again.

Thank you for all your suggestions, everyone!

Keep up this great community 🙂 We got this!!

Re: Filament stuck in the hot end?!

I'm having the same trouble- but over and over. I think I've had the hotted out and apart 3 times, and now I'm looking at having to do it again after only 8 hours of printing. I go to bed and everything is fine; I wake up and the extruder stepper is just ticking as it tries to feed.

If I try to unload the filament, it just shreds at the stepper and breaks there. I can't push it through with a very small Allen key- it's too stuck in the ptfe tube.

After disassembly I pull the ptfe out of the hotted and inside it there is length of PLA with a fat blob stuck at the end of it, preventing it from moving forward or backwards.

I'm really hoping someone can give me some advice as to how to keep this from happening. I'm using Matterhackers Pro PLA through a .40 ruby today.

Best,

Rocco

Re: Filament stuck in the hot end?!

I have had good luck with heating up the hot end, opening the bond tech tensioner, and sliding a very small ball allen down in to the ptfe tube to clear blockage. This has happened to me a couple times when I have let the filament run out.

This is exactly what happened to me tonight, the filament ran out and 'broke' below the gears, so I am going to try this method when I get back from my business trip!

Great info.

Rp

Re: Filament stuck in the hot end?!

Before unloading extrude a small amount of filament. To do so go to settings/move axis/extruder and increase the value by 10

Regards,

Martin

Martin Wolfe

Re: Filament stuck in the hot end?!

Same problem here, ordered new PTFE tube beside other spare parts already. Printer running only for 4 weeks ...

Re: Filament stuck in the hot end?!

Same issue here. It happened 3 times already. I have already replaced the tube twice. For me it happened with both PLA and PETG. Unfortunately, with PETG, it messed up my hot end as well - I have to replace the heathink now. A user has posted a way to cool the part better using a custom printed duct ( https://shop.prusa3d.com/forum/others-archive--f66/filament-stuck-at-top-of-hotend-t15356.html ) . I think I will give that a try next.

Re: Filament stuck in the hot end?!

Just wanted to post what worked for me: I had the same thing. Basically filament stuck in the hotend. Couldn't load more filament to push it through and there wasn't enough filament sticking out of the tube by the gears to pull it out. Worked on it for a very long time. Ultimately what worked for me was to heat it up, remove the nozzle and then stick a straightened paperclip up through the bottom where the nozzle was removed. I had to push very hard but the filament eventually popped up enough to grab it with pliers. If I had tried that to begin with I would have saved a few hours of head scratching.