Re: Filament jammed around pulley...

There are replies but very sparing. Go to the e shop and a chat window will display bottom right open and submit abs you'll be chatting in time

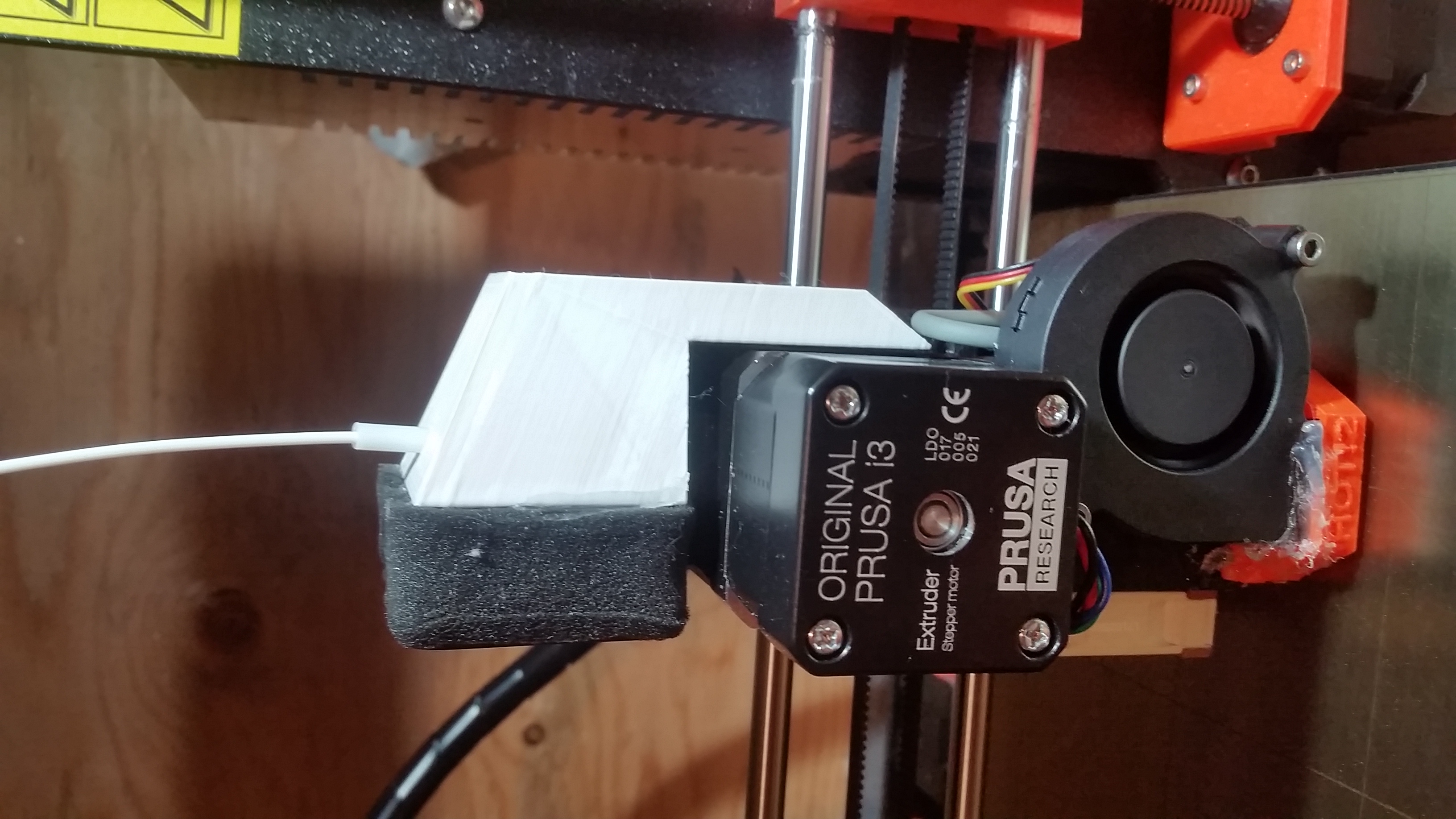

125° is about right for the extruder motor. Here's pix at 16 hrs into a print. Right at the 125° mark

https://photos.app.goo.gl/cSXQplMtbSkkkGV73

Almost sounds like an issue with the heat break. I would be checking out the noctua and heatbreak area.

Re: Filament jammed around pulley...

(This is a repost of my reply to an earlier thread)

I had this exact same issue which began after I started printing in an enclosure. The increased ambient temperature combined with the heat generated by the extruder motor caused the filament to melt between the extruder gears and the bowden tube. See also this thread: https://shop.prusa3d.com/forum/others-archive--f66/clicking-printhead-filament-stuck--t14916.html

My solution: I designed a fan duct to blow air from a 40mm fan into the extruder gear area, it's attached to this post. It's a tight fit so the airflow isn't perfect, but I haven't had the issue since the change. You will need to replace the short bowden tube above the filament sensor with a longer one and drill out the small 'cap' on top of the filament sensor so the bowden tube will fit through it. Let me know if you have any questions.

Re: Filament jammed around pulley...

Ok, I think it's temperature and seems to be aggravated by printing very slow, fine detail areas. I printed three failures in a row of my model, all jamming at the same place, two of them at normal room temperature with no enclosure. Then I switched from S3D to Slic3r for the model. At room temp the Slic3R model printed ok (or it was luck)... But moving back into the enclosure at 86F ambient the Slic3R model failed too.

If it were just the ambient temp I guess I could accept that and just keep it cool, but if printing fine detail at room temperature is too much for it somehow then something is wrong or this design doesn't work.

Thanks for the suggestion about mounting a fan on the pulley... I guess I'll have to consider that. I'll try Prusa support and see what they say... Honestly kind of thinking about giving up on this printer. Every day it's a new problem.

Re: Filament jammed around pulley...

I chatted with Prusa support for a couple of hours... They had me check various things and print a test at a higher layer height. Ultimately the suggestion was to try re-flashing the firmware and doing a factory reset... I am skeptical that this is a software problem...

Re: Filament jammed around pulley...

I chatted with Prusa support for a couple of hours... They had me check various things and print a test at a higher layer height. Ultimately the suggestion was to try re-flashing the firmware and doing a factory reset... I am skeptical that this is a software problem...

I also doubt it, but worth a try. Can you rotate the pulley with you finger, when you open the 'swin door'?

Re: Filament jammed around pulley...

Can you rotate the pulley with you finger, when you open the 'swin door'?

The side of the pully on the door has always moved freely when I have it open, but I believe the side attached to the motor has always been firmly immobile when I've touched it or tried to remove filament jammed around it.

Another data point - I just printed the Marvin that came on the Prusa SD card and I heard it start clicking / skipping at about 48 minutes in.

Re: Filament jammed around pulley...

So maybe heat creep / defect in the hotend. That's too bad. Have you checked that the Noctua fan is in the right orientation? Since it's pre-assembled it's unlikely, but you never know.

http://manual.prusa3d.com/Guide/5.+E-axis+assembly/510?lang=en#s8198

Re: Filament jammed around pulley...

Another data point - I just printed the Marvin that came on the Prusa SD card and I heard it start clicking / skipping at about 48 minutes in.

That is heat creep, might be your ptfe tubing is not seated at the bottom or something else in the extruder is allowing heat creep.

Then again it might be crappy filament.

Re: Filament jammed around pulley...

Then again it might be crappy filament.

It's timely that you mention that because - I think I've discovered that it's the Prusa filament that is causing this!!!

After all of those (half dozen) failures, even in a cool environment I have I just had three successes in a row printing in my enclosure at 90F+ (torture testing it) all with the same model that had been failing... The only thing I changed was I stopped using the Prusa gray PLA that came with the machine and I went back to my old Hatchbox PLA. I even tried two colors of the Hatchbox (black and white)... Both worked fine!

So the question is *what is the difference*? One thing I see is that the Hatchbox lists its temp range starting at 180C and Prusa lists theirs starting at 200C. I remember noting this when I first got the machine because I was used to printing at 190C. Now, before you jump to conclusions, I have been printing all of these tests at 200C or 215C.

So, here are a couple of possibilities:

1) The Hatchbox PLA's lower melting point means that it's putting less back-pressure on the extruder. Not sure why the time or layer height factors would influence that though. 2) There is just something wrong with the gray Prusa PLA - maybe it has voids in it or some other irregularity? It looks so perfect the way it's coiled on the spool that I just assumed it was fine and never even thought to try another until now.

Has anyone else who's having this problem tried switching filament?

Re: Filament jammed around pulley...

30° is OK, but not much more.

Thomas

Prusa recently posted a video about building cheap enclosures in which they talk about running at 40C for printing ABS. But In their more elaborate enclosure they do move the power supply and filament outside the box.

Re: Filament jammed around pulley...

It could be Prusa’s silver filament... I had the same problems, and after switching to other HQ filament, the problems are gone...