Extruder wiring simplification

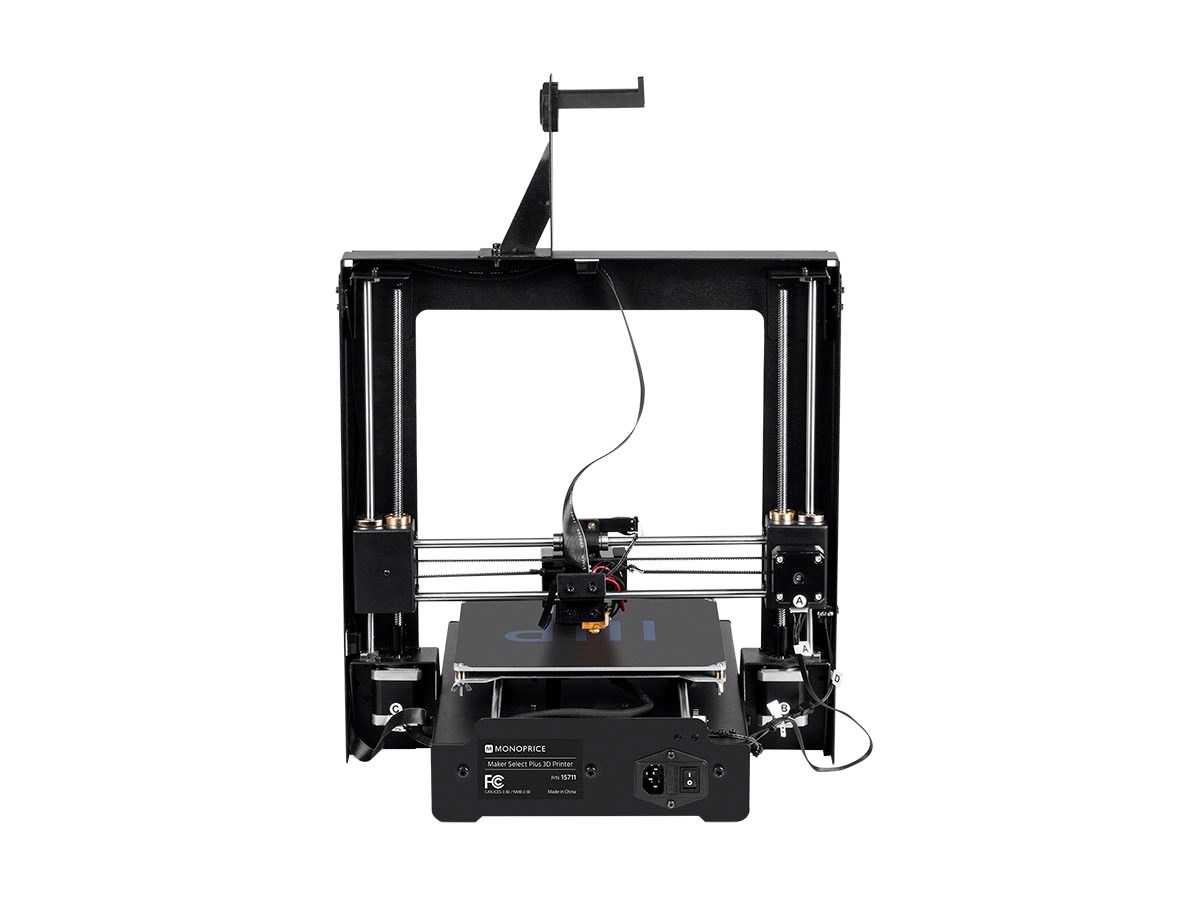

After being down for another week due to the print cooling fan wire breaking, after having been down for a pinda wire breaking, I am kinda tired of having to solder wires and i am wondering why prusa does not innovate and copy the monoprice select i3 plus. a terminal box at the back of the extruder with a nice flat flex cable to go back to the control box

this would be so much nicer than the wrap which allows wires to get pinched and broken. plus assembling the extruder would be much faster and much more reliable.

Re: Extruder wiring simplification

That is like an idea that i have been contemplating

Do you know how they handled extruder heater power and crosstalk between the signals?

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Extruder wiring simplification

That is like an idea that i have been contemplating

Do you know how they handled extruder heater power and crosstalk between the signals?

Regards Joan

http://www.mythoughtspot.com/2017/09/18/wanhao-duplicator-i3-plus-ribbon-cable-pinout/

apparently they split it up among several wires on the ribbon to lower the amperage needed on each.

Re: Extruder wiring simplification

guess somebody needs to try it on the I3 mk3...

there would need to be more signals for the pinda and filament sensor

wonder if there would be any crosstalk between heater and extruder motor phases, Pinda, fan tacho wires or filament sensor?

we would have to keep the fan power separate from heather power because our fans are 5volt and our heater is 24 volt

personally I would like to keep all of the signals separate which would require more pins/wires in total

It's do able, all we need now is someone with too much time on their hands, and the desire to play...

benefits I can see are

replaceable Flex section of cable

Possible simpler strain relief , probably no need for the spiral wrap or braided cover (ideally the cable would run in a straight line with all bending moment perpendicular to the width of the ribbon cable, configured similar to a cable chain to spread the flexure along the length of the ribbon cable rather than concentration it on small sections of the cable length.)

relatively simple interchangeable hot ends, maybe volcano and standard v6 hotend, or Skelestruder / mosquito etc.

reduced cable drag on extruder/X axis

problems I foresee are potentially more rapid cable failure, normal ribbon cable is not particularly flexible

(the power issue is mitigated by the hot end being 24 volts and therefore lower current than a 12 volt heater)

inkjet ribbon cables are normally a very thin plastic film with extremely thin conductors on the surface... these are designed to be very flexible and last millions of cycles, but carry very low current

probably need locking connectors to prevent the connectors shaking loose on the X carriage

So, let me know when you try it... 🙂

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Extruder wiring simplification

Even if they were to use separate power and data wires, it would still be less rubbing in the wrapped cord. So many PITA tasks would be improved if the extruder had some sort of connector(s) to allow removal in 10 minutes or fewer. You could even make a stand-alone Arduino with a subset of RAMPS parts to heat the hot end and monitor the thermistors to make blob and clog removal a snap.

When someone asks you if you're a god, you say, "YES!"

Re: Extruder wiring simplification

After being down for another week due to the print cooling fan wire breaking, after having been down for a pinda wire breaking, I am kinda tired of having to solder wires and i am wondering why prusa does not innovate and copy the monoprice select i3 plus. a terminal box at the back of the extruder with a nice flat flex cable to go back to the control box

Yes, yes, a thousand times yes! This is my biggest complaint about the Prusa design: sooner or later, everyone has to replace some part on their hot end, and with the current design that means completely disassembling the cable bundle and putting it back together. A huge PITA and it takes forever.

My three prior printers were all TierTime models, and the TierTime printers all use a single ribbon cable which terminates on a breakout board on the hot end. Replacing a fan, heater, etc., only requires unplugging the broken part from the breakout board and plugging the new one in. What would be an hour on the Prusa takes five minutes, plus the odds of a cable failure are much lower since there's a proper flex cable for the parts of the cable that flex.

Re: Extruder wiring simplification

That is like an idea that i have been contemplating

Do you know how they handled extruder heater power and crosstalk between the signals?

Regards Joan

http://www.mythoughtspot.com/2017/09/18/wanhao-duplicator-i3-plus-ribbon-cable-pinout/

apparently they split it up among several wires on the ribbon to lower the amperage needed on each.

That would be a great upgrade! - And first step towards multi toolheads, like E3D is experimenting with: https://e3d-online.com/blog/?p=657

As the MK3 has lot of wires the plug could be DB25 or similar.

Have a look at my models on Printables.com 😉

Re: Extruder wiring simplification

There are flat ribbon cables made with very finely stranded conductors, so they are very flexible. For just one example, http://www.alphawire.com/Home/Products/Wire/Hook-Up-Wire/Ribbon/3532?device=pdf

I agree with Joan that you probably want to use at least two "going" and two "returning" conductors for the heater to spread out the load.

It would be best to place the low-level signal wires from the thermistor, the PINDA sensor, and the filament sensor on one side of the cable, and the highest-power circuit for the heater on the opposite side of the cable. The motor wires and fan wires would be in between.

If it were up to me, I'd have the components on the extruder each plug into a header or junction block individually, and then have a combined cable go from the header to the control board. In this way, you could replace a fan, a heater, or a sensor without having to disassemble the whole extruder assembly. In this scenario, it's not even crucial that the cable from the extruder to the control board be a flat ribbon cable; it could be a round, jacketed cable. An advantage of round multi-conductor cables is that it's easier to get them made with twisted pairs (even shielded twisted pairs) than it is to get twisted pairs on ribbon cable. Twisted pairs will greatly reduce cross-talk between circuits.

Re: Extruder wiring simplification

Id be real worried about the heater cartridge burning out the wires, most ribbon cables are only 28awg. If we could find one with 20awg that would be ideal. Or we could run two ribbons one thin gauge for sensors and fans and one bigger for the heater cartridge.

Re: Extruder wiring simplification

I'm new here and not sure how helpfull...

Why not a breakout board on the back of the extruder unit with a 25pin DSub connector and one 25wire cable to the Einsy board? 2 or 3 wires of 25 should be enough for the extruder heater.

Re: Extruder wiring simplification

I've been day dreaming about this idea for a year! (I'm not in a position, time wise, at the moment to want to play with it on my own - but I do have time to be a squeaky wheel at Prusa). Anybody have any advise on what would be the most effective way to push this as a feature request.

Re: Extruder wiring simplification

I would be glad if they just replaced all the wiring with the high flex silicone insulated equilivent

https://smile.amazon.com/EvZ-Conductor-Temperature-Resistant-Extension/dp/B07D3MVRMR/ref=pd_rhf_gw_p_img_7?_encoding=UTF8&psc=1&refRID=Q86CVSBRFRVX0AHA9MS0

sold in sizes from 24 AWG all the way up to 8 AWG (12 AWG should be plenty the high current wires and the 24 for the signal wires.

there are too many failures due to flex problems and done with high flex fine conductor they would no longer be a problem... if I ever do a major upgrade they are what I would use.

Re: Extruder wiring simplification

i would much rather replace a single cable, then have to un/rewrap and possibly damage an individual wire for something like a heater or fan cable that already experiences alot of flexing. it opens the ability to put the hardware in another location that wont be exposed to heat (lack table or other enclosure for high heat printing. having to unbundle every wire and still have them connected while doing maintenance introduces more issues. having the ability to quickly remove/replace/rebuild a full extruder mount by unplugging 1 cable, and putting a specialized or test head for special prints is what i feel would outweigh the feeling that a ribbon/flex/printerStyle cable breakage is the only concern. im already trying to source parts and figure out how easily this can be done just for the print head, then ill goto the X/Y/Z motor breakouts.

really, a simple wire bundle and locking molex brand/style connector (search "molex mini-fit jr.") would remove alot of frustrations. unplug, 4 screws, and the entire head is off, and i can goto my workbench with just that to work on.

i have had so many feeding issues in the past month, that i just want a way to fix/replace the head while another head does the printing. this changing method could also be good for those running the MMU, you can put the MMU head, or the single head quickly, based on the project. E3D is already working on the tool head changing, get in touch with them, work with them, be the guys that help introduce the auto tool changer, or the manual quick changer. in all honesty, im waiting on that for MMU projects.

there are several parts of the printer that just need to have plugs for easy change, routing, or general maintenance without the need to fully disassemble the printer. im already working on changing the PSU cabling this week. and assessing the maximum size of the extruder flex cables and a good universal (easy to source) plugs. then its onto the heatbed cable if i feel it needs love.

and we’ll be saying a big hello to all intelligent life forms everywhere … and to everyone else out there, the secret is to bang the rocks together, guys.

Re: Extruder wiring simplification

Fantastic idea - subscribed.

--------------------

Chuck H

3D Printer Review Blog

Re: Extruder wiring simplification

I agree Migamix, and idealy there would be one cable for power and another for all forms of data multiplexed .

look at the way something like a car was wired in the 60s s or 70s even a very complex car filled with lots of gadgets... every thing had its own wire loom.

today fancy electronics in cars have their own data buss system. I recall reading that the BMW system saves several pounds of copper in each car but more importantly it greatly sped up the build of the cars.

this hobby is still in its rapid growth youth. but in time I expect all data needs to be supported on one simple network and power needs might even be multiplexed on it to make things like simple hot swappable hotend/extruders a possibility.

the e3d tool head changer has a shot at becoming an industry standard but it is still to early to see how it will do... my knowledge of it is limited to the Videos that Thomas Sanladerer has done recently but it still looks to be a good way from a shipping product.

Re: Extruder wiring simplification

Here's a multi-conductor connector that is intended for mixed LF, HF signal and power lines.

Cost might be a bit prohibitive, but the configurable connector is elegant. They are vibration resistant and can go up to 3 row and 120 pins!

Still haven't quite figured out their online configurator to get a ballpark price.

Then there's the issue of tools needed to make the correct crimps

https://www.nicomatic.com/product-cmm_micro_connectors-21-en.htm

Re: Extruder wiring simplification

pretty much every high end printer uses some sort of disconnects and/or ribbon cables for this exact purpose. seriously, watch someone do a head swap on a taz or better yet an ultimaker.

wishlist for mk4?

Re: Extruder wiring simplification

It doesn't help that the current wiring management feeds between different levels of the x-rods. You can pull the head without undoing the entire wiring harness or the x-axis. If the wires were at least ALL routed below the bottom x-rod or above the top x-rod, the print head and x-axis could be serviced independently.

Ribbon cable connectors and a 3-D printed, lock down mechanism would be a doable alternative.

Re: Extruder wiring simplification

Bottom-line: the reason why the extruder connections are "hard-wired" today is for long-term reliability.

It's simple, and it works.

See the i2c errors you can get on an Ultimaker with it's fancy custom swappable hot-ends for why this isn't done today on the Prusa platform.

Not that there wouldn't be some "neat" advantages, for instance:

If you simply made the connection modular, then you could "swap" hotends, much like the Lulzbot, but the lulzbot "harness" is crude and this would require manual reconfiguration to "inform" the printer of the extruder changes; much as on the lulzbot platform where you just flash the printer to be a different printer, not so modular, really.

But really you would only require 3 wires going to the hot-end, 24v power for the extruder and a one-wire self-clocking protocol for the "smarts": PINDA, PINDA thermistor, filament sensor data, thermistor data, heater mosfet control.

And to eliminate the reprogramming aspect, you would simply add some form of small *PROM onto the "thing" which could hold encoded specifics about your hotend: steps/mm, nozzle size, probe offsets XYZ, *material compatibility*, or even additional capabilities such as spindle speeds, laser focus, etc.

(you can see how "blue sky" this is by now I'm sure).

To maintain the "hobbyist" aspect you would of course be able to acquire "blanks" onto which you could specify your own offsets and capabilities, the encoding being extensible to allow future use-cases.

Together this "thing" I describe would permit significantly simplified toolhead wiring (from 19 conductors to 3) , and possibly allow for universal attachment of various capabilities onto the "platform", at the expense of significant re-work of pretty much all critical aspects of the machine.

A the very least this entails retrofitting all the various AtoD and mosfet controls onto a separate board, encoded over this mythical protocol, plus developing and implementing the encoding scheme and capabilities matrix for the "thing", and forking the firmware, etc.

I've put some thought into it, I just don't have the time...

Maybe when E3D comes out with the integrated nozzle/thermistor/heater "thing" then the situation will change somewhat.

Re: Extruder wiring simplification

lee.o,

An excellent outline of the problems with doing this the right way... reliable connectors (milspec can be a good indicator) and high spec flex wire will help but of course all these things add to costs not just of the parts but engineering production, and support.

if the e3d folks get their hot swappable extruder/hotend product developed and into production at a reasonable price I think it may have a shot at becoming the kind of standard their V6 hot end has become with higher end kit producers like Prusa... will I live long enough for it to be useful to me before I am in my dottage?

well I hope so and the glance I saw of its current state of development in this youtube video from Thomas Sanladerer holds true it might and I can see why they are taking a "automatic tool changer" as used in CNC machine tools as their approach to the problem being a good one. I hav not found out many details of this e3d program other than the video though. if they pull it off as an open source project it might see wide adoption in the hobby nut just as a full product but for usage where the user changes the "tool" when they want to at the simple end; all the way to having a rack of as many units as you wat already fed by their filaments ready to change color and type of plastic as needed by the model with out the creation of huge purge blocks at each change.

is this blue sky? .... well yes but at 10 years out It could be the future of the hobby... I don't see liquid resin systems with their chemical mess and smells and the same again at a cleaning stage getting very wide acceptance any faster.