Extruder slipping - have tried all the standard troubleshooting

I have several thousand hours of prusa printing (2xMK3S+ and Mini) and I have been able to work through repair and maintenance issues over the years. Recently I was using a cheap PLA filament for a large amount of Sci-fi models. After that large amount printing I started to have problems with extruder slipping and clicking. I have tried all the usual troubleshooting. And of course I am not using that filament brand again.

I have read that the brand of PLA has issues with inconsistent filament diameter. Given that I have tried all the standard troubleshooting methods without success, If the inconsistent filament diameter damaged a part of the printer, which parts should I consider changing to fix the problem? Hotend or extruder?

Would inconsistent filament be more likely to damage extruder gears or the 3d printed parts around the extruder gears or something in the hotend?

Thanks,

Tom

RE: Extruder slipping - have tried all the standard troubleshooting

I had a similar situation a while ago. I found out that two things were happening: First, the clicking noise came from a bit of filament that somehow got stuck behind the extruder gear, and second, when I inspected the gears more closely I saw that over the years the 'teeth' of the gear had lots of filament in them that accumulated there over time. I carefully removed this with a sharp tool and cleaned the whole thing thoroughly. The problems were gone after that.

I don't know if you have the same problem, but hey... it would be simple enough to check before you go on to replacing parts...

Good luck!

RE:

I too had a similar situation although the extruder clicking was very quiet. Quieter than extruder skipping I have experienced on other printers. Originally, I investigated the zits and layer adhesion due to the breaks in the print.

Searching for causes led me to try a range of tuning and changes to try to either eliminate and/or isolate the cause as follows:

- clearing the nozzle using cold pull technique

- first layer calibration/tuning

- changing filament

- drying filament

- fresh/new filament

- idler tension

- extruder steps

- extruder flow

- drive gear alignment

- ensured the drive gears were clean

- checked the PTFE tube

- temperature towers to tune print temperature

- changed the hot end (as I had a Revo installed and returned to the original) to eliminate the hot end as a potential source of problems and figured if I needed to go through Prusa support this might be helpful.

The tuning was very successful the and saw improvements to print quality and at times I thought some reduction in the problem. After all that I was getting extremely good first layers and very accurate prints except for the intermittent holes in the print. By this time it was very clear that the problem could appear anywhere in the print including on the first layer, infill, perimeters, close to print corners, middle of a straight section or just before a corner.

By this stage I was pretty sure the problem must be related to the extrusion path and happened on this post. I new that I did not have any filament stuck as I had partially disassembled the extruder but then also changed the hot end. So I decided to go back and look at the extrusion path and immediately started get some more issues including noise and skipping when loading filament.

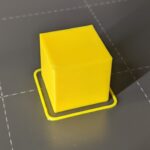

Upon opening the idler door and checking the idler gear it became apparent that the idler mounting shaft was not sitting properly in the 3D printed idler door. I tried re-centering the pin but it seemed to be too loose a fit in the print. I have a spare set of all the 3D printed parts so I tried assembling the gear, bearing and pin into the spare. The fit of the pin was much more secure (although when mounting the door it was much looser on the extruder).

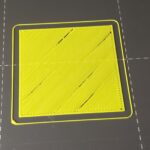

I have run of a couple of prints since swapping out the door and the results have been excellent per photos.