Extruder skips towards the end of the print

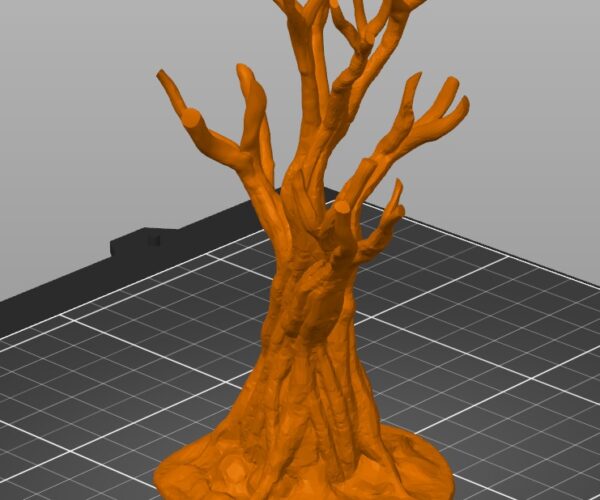

Hello everyone,I've run into an issue with my Mk3S+ while printing semi-complicated prints. I've been printing some trees for tabletop games and about 85% towards the end of the print, when the "branches" are printed, I get extruder skips in irregular frequencies.

This does affect print quality to the point of the print being damaged. There is a workaround, which albeit annoying, allows the print to complete - once the skips start, I perform a filament change and the print then continues for anywhere between 15-30 minutes until the skipping returns.The pulled filament looks clean and well shaped. I've also performed several cold pulls (with standard and cleaning filament) which looked fine that didnt help with the issue... The nozzle is like 4 weeks old, but I strongly suspect the issue is related to the nozzle. Im slicing with the prusa slicer with very standard settings and the premade profile for the filament I use (Das Filament), so no deviations there and I assume its a hardware problem and not related to the slice.

It's a prebuild kit, so no assembly mistakes on my part 😉 I admittedly had to take the extruder apart a month or two ago since the filament broke off and was stuck in the PTFE tube, but since the print performs well for about 4h and the issue always reappears at the same stage I dont think its a general extruder problem.

I also printed like 20 of these things earlier this year (but sliced with my standard cura profile before I switched to Prusa Slicer), so thats another hint that the STL itself is not at fault.At this point I'm tempted to change the nozzle to a fresh one and see if that helps, but changing the nozzle every 2-3 weeks sounds like a rather expensive fix 😉 But I'm out of ideas otherwise..Has anyone else experienced such issues and can provide me with a pointer as to what to check and/or do?

Best Answer by Neophyl:

I've attached a project of how I'd print that tree without too many changes to the base settings.

The filaments slow down if layer time settings were the default and as I thought when it gets to the higher parts it was slowing the print down to 15mm/2. This means the filament is staying in the hot zone longer and combined with retractions most likely is resulting in the heat creeping upwards. Maybe enough that those 3-4 degrees ambient would tip the balance. I've increased the filaments minimum speed to 25 the same as your external perimeters speed and also changed the time to 5s instead of 15. Pretty much all of my pla filament profiles have those changes as it helps with printing tall thin things.

With the base size of that tree if its not sticking enough that you need a brim then something is wrong with your plate adhesion. Either its not completely free of grease and/or your live z is not dialled in. Plenty of threads on here that detail how to sort those out (about half the posts on the forum are for those 2 items it feels like 🙂 ) Seriously with that much surface area it should be stuck like a limpet.

The way its designed it doesn't need any supports. There's no overhang sufficient to warrant them. Will print quicker without.

Changed infill to cubic. Similar weight to strength ratio as gyroid but doesn't shake the printer as much on long runs and uses less gcode as the lines are straight.

On my printer I have retractions turned down to 0.6mm and I have retract at layer change turned OFF. However the reason I can get away with that and still have very little stringing (even printing hotter than recommended) is that I calibrate my filaments. By that I mean I measure the average actual diameter of the filament with a calliper. If its 1.76 then I change the default from 1.75 to match the real world value. Once that is done, in practice I've found that extrusion multiplier hardly ever needs to be touched. Making sure that one value is accurate tends to be enough.

If you think about it that one assumption of diameter is the building block of every calculation the slicer does on how much plastic to extrude. If the filament is a bit under sized then you get a bit of under extrusion, if its thicker then it puts out too much and contributes to problems like stringing and also rougher top layers or slightly oversized parts.

RE: Extruder skips towards the end of the print

Its quite possible a slicer setting, as using a different slicer doesnt cause the issue according to your post. I rather doubt its the nozzle.

Save the project (File>save project as) and then take the 3mf file and zip it up. Attach the zipped file to a reply here. Must be zipped or the forum wont accept the file type.

With the project we can slice and look for problem areas. as we can slice it with the same settings you are using and then use all the various tools to check layer by layer.

One possibility like on the thin branches it may be doing many many more retractions, which could be causing heat creep and as such extruder skips which might not occur on the thicker parts. That's just one possibility. Combine that with the generally higher ambient temps at the moment, higher ambient always causes more of these types of posts on the forum historically.

Another possibility is the slowdown when layer time settings, once layer time drops below a certain configured time then the printing gets slowed down. That can also cause feed problems, and does cause part cooling problems which results in more curls and then the extruder hitting raised filament.

With a project its less guesswork 🙂

RE: Extruder skips towards the end of the print

Wow. Thats great food for thought, thank you very much!

So there's a To-Do list for me now to troubleshoot, which is great in itself 🙂

1. post the *.m3f Gnarled Tree - Done 😀

2.Try and reslice the stl with Cura as a direct comparison. See if issue persists. I assume the Prusa Slicer has different retract settings - plus the profile in Prusa Slicer has a printing temp for 210°C for Das Filament while I used 215°C in Cura. I'm not familiar with slowdown settings in Cura - I didn't drill that far down into it, but I could compare the settings between the two slicers if solved.

3. If issue doesn't appear with Cura, try printing with 215°C in Prusa Slicer since that one is the obvious difference. Then see if layer time slow down causes the issue.

4. Last option then would be to try and print overnight with lower ambient temp. I don't think it will make THAT much of a difference, a few °C at most... I was not aware that a temp diff from like 4-5°C can affect a print that runs in the low 200's. But gotta rule out the factors one by one.

RE: Extruder skips towards the end of the print

Thanks for the file, i'll try and take a look after work 🙂

As for the ambient temp, the v6 extruder on the mk3 is ambient air cooled (like most extruders). Now they are 'rated' to be ok up to 40 degrees, however I've seen (and experienced) issues in the low 30's. The higher the ambient the lower the temperature difference slope so the more inefficient the cooling gets. In practice its only really a problem with pla and happens most if you print inside an enclosure. Its why all the advice is to print pla with your enclosures doors open. However I don't know where you are geographically but recently in the UK we have had some 40+ days, which is hotter than my enclosure normally gets with the doors shut lol.

Hence the warning to keep the ambient in mind. Hang around the forums long enough and you start to see the trend of more 'my extruder is skipping' posts during hot weather.

RE: Extruder skips towards the end of the print

I'm based in Germany, we've had quite a few good hot days as well. Not reaching the 40s (yet,) but 37°C or so was possible. Now I don't have that inside my flat for obvious reasons, but neither do I have an AC. And with the air sitting still with no wind, reaching 30s inside this room is plausible. Living room has 27°C usually...

Lesson learned!

Print FDM in the winter, SLA in the summer 😛

What's still confusing me a bit though is why the filament change helps. Working theory - the break in printing allows it to cool down a little bit. Doesnt fit with my understanding of heat creep, but that would fit the bill more than different slicing.

RE: Extruder skips towards the end of the print

I've attached a project of how I'd print that tree without too many changes to the base settings.

The filaments slow down if layer time settings were the default and as I thought when it gets to the higher parts it was slowing the print down to 15mm/2. This means the filament is staying in the hot zone longer and combined with retractions most likely is resulting in the heat creeping upwards. Maybe enough that those 3-4 degrees ambient would tip the balance. I've increased the filaments minimum speed to 25 the same as your external perimeters speed and also changed the time to 5s instead of 15. Pretty much all of my pla filament profiles have those changes as it helps with printing tall thin things.

With the base size of that tree if its not sticking enough that you need a brim then something is wrong with your plate adhesion. Either its not completely free of grease and/or your live z is not dialled in. Plenty of threads on here that detail how to sort those out (about half the posts on the forum are for those 2 items it feels like 🙂 ) Seriously with that much surface area it should be stuck like a limpet.

The way its designed it doesn't need any supports. There's no overhang sufficient to warrant them. Will print quicker without.

Changed infill to cubic. Similar weight to strength ratio as gyroid but doesn't shake the printer as much on long runs and uses less gcode as the lines are straight.

On my printer I have retractions turned down to 0.6mm and I have retract at layer change turned OFF. However the reason I can get away with that and still have very little stringing (even printing hotter than recommended) is that I calibrate my filaments. By that I mean I measure the average actual diameter of the filament with a calliper. If its 1.76 then I change the default from 1.75 to match the real world value. Once that is done, in practice I've found that extrusion multiplier hardly ever needs to be touched. Making sure that one value is accurate tends to be enough.

If you think about it that one assumption of diameter is the building block of every calculation the slicer does on how much plastic to extrude. If the filament is a bit under sized then you get a bit of under extrusion, if its thicker then it puts out too much and contributes to problems like stringing and also rougher top layers or slightly oversized parts.

RE: Extruder skips towards the end of the print

Holy ****.

I'll print that tree as you provided. I have 4 more of these trees for diversity reasons, so I'll update my settings according to your recommendations. If I ever figure out where and how 😀

But if heatcreep is the problem (and I totally believe you), wouldn't a better heatbreak not work in resolving? I think I have a steel/copper one flying about somewhere here... Just have to install it.

I usually just go with a brim. Might not be super efficient, but its better to have a brim as a rule of thumb than not to have it 😀 GOt a bit burned from the Vyper I had before the Mk3S... edges lifted off all the time from that thing.

RE: Extruder skips towards the end of the print

Well scratch the heatbreak, its a different version with only threads on one side. Sad 😉

Also nvm, found the settings by just saving the changes you did in the project.

Now I just gotta wait for the "sanity print" (my own... something simple, but I need a success :P) I started to complete and test it!