extruder scratching infill

Hi Everybody,

My extruder keeps (slightly) scratching my infill -> the lines rattle while being crossed no matter the layerheight (0,3mm / 0,15mm)

or my z-height (already changed from my supposedly ideal -0.995 to -0.800 with no effect)

there are no other problems whatsoever it seems the shells aren't affected at all, the layers are very clean

the bed too, calibration looks good it seems the problem was always there since i often heard the rattling before

but could hardly see it, now that i am moving to bigger modells i'm afraid something might get damaged and the sound is driving me insane

i hope this wasn't posted before but afaik nothing seemed to exactly match my problem

firmware is from march 8th

Re: extruder scratching infill

Perhaps you are over extruding? Try reducing the extrusion multiplier a little.

Re: extruder scratching infill

Perhaps you are over extruding? Try reducing the extrusion multiplier a little.

Re: extruder scratching infill

thanks, will try that, my toplayer did always seem a little rough looks like further evidence

Re: extruder scratching infill

WOW !

the toplayer already looks so much better !

i went "crazy" and used a Multiplier of 0.9

thank you so much, i read about the EM but just didn't realize

it could help with my Problem(s)

UPDATE:

it is completely fixed, i used stealth mode and could not hear a single

scratching sound !

Thanks again,you were a great help and i learned something today

UPDATE 2:

There is still a large print that scratches small ones seem to be OK i'm a little confused

Re: extruder scratching infill

It might help if you posted some pictures...

Have you ever tried a simple extrusion test? Here is a simple one: https://www.thingiverse.com/thing:1796601

The basic idea is that you print a single bottom, single walled cube with zero infil and with "vase mode" selected. The latter means the extruder will never lift from the object. You only need to print about a 1/3 of the height. Then measure the wall of the cube with calipers. You want the wall thickness to match the extrusion width set in your slicer. If it doesn't you need to adjust the extrusion multiplier. One other tip: it is better to set your extrusion width a little bitter than your nozzle size. I find 0.45 works well. Setting it to that exact nozzle diameter is fighting physics for perfect extrusions.

If you have done the above and are still having problems then make your you first layer offset is perfect (can be tricky with current temperature dependent PINDA issue).

Good luck.

Re: extruder scratching infill

Thank you for your kind reply.

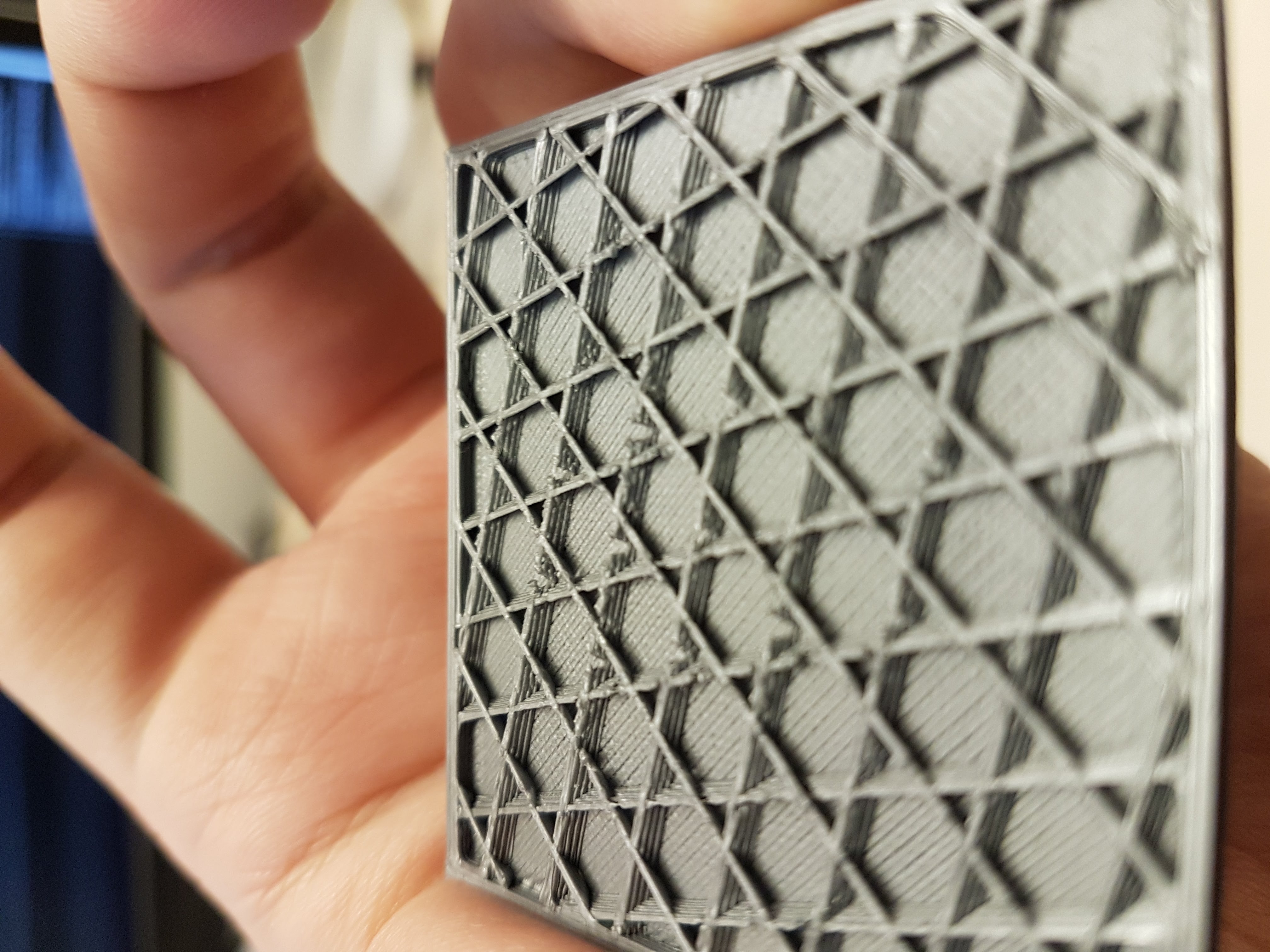

Not sure you could even see my issue on a picture i can hardly see it. -> attached it anyway

I'm more or less just detecting it by the mentioned rattling sound when crossing multiple lines.

"3D-Honeycomb"-Infill fixed it for the time being but i'll try to print the cube and measure it as soon as possible. (the calipers are on their way 😉 )

I should mention that i have already printed several multipart modells that seem to fit perfectly together.

Does that say anything about my extrusion-precision?

You meant the extrusion width should be a litte wider than my nozzle?

I think there was a typo or my english is not good enough 😉 (i'm german)

The extrusion width is already at 0.45, the Slic3r PE default for my MK3.

In the picture you can see the cross-sections of the infill being more "shiny" i think thats caused by the extruder

scratching over it.

PS.: sorry i'm so late my notifications do not seem to work

Re: extruder scratching infill

Unfortunately i'm unable to print any of these "cubes"

i does not print anything, no matter if vasemode on/off 100% infill or 0%

Re: extruder scratching infill

I could not get your suggested "thing" to print but found another that claims to have 0.8mm wall thickness

while i measured almost exactly 0.85 (3 sides 0.85 1side 0.86) divided 0.8 by 0.85 and got 0.94 EM.

What i don't understand is why the MK3 often shows Flow = 95 under tune while printing even if Slic3r PE says EM 1.00.

Should i set my measured EM in Slic3r or will the MK3 Firmware multiply that value by 0.95?

I mean 0.95 is pretty close to the 0.94 so why is the wall thickness that much of?

After some prints i have an EM of 0.93 which almost gives the perfect 0.8mm BUT the problem persists.

I would say it scratches a little less but it's still audible and i think visible.

Re: extruder scratching infill

Just realized i'm not the only one and the behaviour is obviously wanted:

https://shop.prusa3d.com/forum/others-archive--f66/nozzle-bumping-against-infill-t14229.html

See also attached picture.

I will just permanently switch to Honeycomb or 3D-Honeycomb then.

Re: extruder scratching infill

I still haven't been able to fix this on my printer. Below is a short list of my attempted fixes and experiences:

A friend suggested this issue might have something to do with it, but I don't know.

Re: extruder scratching infill

Was this problem ever solved? I've seen multiple people with this issue and only one person fixed it, but they changed so many things (including a whole new extruder!) I'm not sure where to start. My printer is currently grinding on infill as well, and it's making me quite concerned and keeping me from printing big prints.

Re: extruder scratching infill

Have you tried a different infill?

Say gyroid?

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: extruder scratching infill

There is an entry in the start Gcode. That sets flow rate to 95% for most layer heights.

This is independent of extrusion multiplier. So if you change the extrusion multiplier on Slic3r. The Gcode commands for extruder feed rate will be changed. Independently of the flow rate setting.

If you change the flow rate on the LCD the printer will readjust every extruder feed instruction. As the print progresses.

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: extruder scratching infill

I just discovered this problem as well...Is it over extrusion? layer height adjustment? is there a solution?

for reference I am using hatchbox PLA (blue) if that matters. I didn't have this problem with the Prusa filament that was sent with my printer, then again I only printed smaller things with not much infill with that filament.

Re: extruder scratching infill

try reducing flow on the LCD

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: extruder scratching infill

try reducing flow on the LCD

Joan

Hi Joan,

I am currently checking some strange effects with a new roll of white Fillamentum Extralfill by printing multiple xyzCalCubes-G-codes (varying the extrusion mulitplier [EM] and extruder temp via Slic3r) ...

Let me rephrase what I understood from your posts - adapting the EM in Slic3r changes the flow-rate for each G1 command in the G-code-file but on top Prusas "M221 S95" command that is issued at the beginning of each run will reduce the extruder flow on top by 5%. If I go change the extruder flow in the LCD menue during a print it would be like changing the M221 command right at the beginning. Is that the correct understanding?

This would make my job hunting under- and over-extrusion much easier ... but what puzzles me is: why are there two levers aiming at the same thing? EM reduced to 0.95 and M221 S95 would then have the same effect as reducing the EM to 0.90 and removing the M221 command - or am I missing something?

Cheers,

Mark

———————————————

MK3 kit B7-R3 / custom FW v3.5.1 with 7x7 MBL

Slic3r PE v1.41.2

Re: extruder scratching infill

Hi Mark.

Steps per millimetre. Extrusion multiplier. Flow and M221 all do similar things

With varying levels of complexity and understanding

Flow is quick and easy

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: extruder scratching infill

Hi Mark.

Steps per millimetre. Extrusion multiplier. Flow and M221 all do similar things

With varying levels of complexity and understanding

Flow is quick and easy

Joan

Got it ... thanks!

———————————————

MK3 kit B7-R3 / custom FW v3.5.1 with 7x7 MBL

Slic3r PE v1.41.2

Re: extruder scratching infill

Hi Mark,

I was on my mobile earlier

lets imagine a perfect world...

your filament is spot on 1.75mm

your extrusion multiplier is set to 1

and your layer height is high enough for Joe Prusa's M221 S95 to kick in and take effect

when your model is sliced, every printing move will be accompanied by a carefully calculated squirt of hot filament based on the chosen settings, including linear advance (with perhaps a sprinkling of magic.

this information will be included in the resultant Gcode data file... carefully preceeded my the command string M221 S95

when you select and execute the Gcode, the printer will accept the M221 S95 instruction, and use it to re calculate new reduced filament feed values for every printing move...

If you choose to interfeer with this situation, by tweaking the Flow value in settings, you may notice that the initial stored value is 95%.

manually changing the flow value should give the equivalent effect as changing the M221 S value. however flow is immediate, where as changing the S parameter means editing code and re slicing plus restarting the print.. (you can always update the value for the next print!

if we then upset the perfect setup by using say... TPU, now your perfect setup is likely to be under extruding. if you increase the extrusion multiplier to 1.2, to compensate, ... but the M221 command will still reduce the overall filament fed to the nozzle, and any Flow changes will change extrusion values as before...

hope this makes sense,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK