Extruder Clicking 0.10 layer height

Hi all,

I've been using my MK3 for a while now on 0.2 layer height, works great and the quality of the prints is terrific.

However I'm now trying to print at 0.10 layer height and it doesn't work.

The extruder starts clicking and no filament makes it out of the printer anymore.

Things I've tried:

- Realign extruder gears

- Playing with extruder tension

- Disassembled extruder to make sure the ptfe tube is inserted all the way into the hotend

- Thoroughly cleaned the nozzle

The first layer prints fine as it's printed at 0.2 layer height (slic3r default).

But after that it starts failing fast.

My thoughts are that it's related to the extruder or the z layer height somehow.

I'm trying more things but if someone has a good indication to what the issue is from experience it would help.

Thanks

Re: Extruder Clicking 0.10 layer height

I would wash the build pate then raise the Z offset abit. OR try .15 first.

I have a Prusa,therefore I research.

Re: Extruder Clicking 0.10 layer height

Hi Greg,

when does this problem start?

are you trying to use 0.1 mm first layer? (first layer should be 0.15 or larger, upto 80% of nozzle diameter)

is it the second layer,

is it some time later...

could it be a retraction issue? perhaps you are retracting too far... I normally reduce the standard Prusa retraction distance

do you have any pictures?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Extruder Clicking 0.10 layer height

Hi all,

So as I mentioned, the first layer prints at 0.2 fine, 2d layer it starts printing at 0.1 and it fails rather quickly.

Actually to make sure it's not slic3r related I'm now printing the provisioned gcode from Prusa on the SD card.

- So the Prusa Buddy at 0.15 layer height prints fine, no issue.

- Trying to print the Prusa Marvin at 0.10 layer height however starts failing fast (picture attached)

You can see it stops printing but even before that there's a skipped layer.

As I mentioned I printed this directly from the Prusa files to avoid Slic3r settings.

Re: Extruder Clicking 0.10 layer height

looks like air printing/partial jam or clog there

Re: Extruder Clicking 0.10 layer height

Slow the print speed down.

Try printing hotter,

or with les fan speed.

Try extruding by hand, is the extruded material in a straight line.

Re: Extruder Clicking 0.10 layer height

Sorry, it's been a while since I updated this post.

Reason is that i accidentally cut the heating wires on the hotend while removing the nozzle ...

I had to wait for a replacement to arrive.

Anyway, I seem to have resolved the issue of printing at 0.10 layer height through mechanical tinkering.

However 0.05 still posed an issue.

The only way I found it posssible to print at 0.05 is to set the extrusion multiplier to 0.9 and up the nozzle heat to 220.

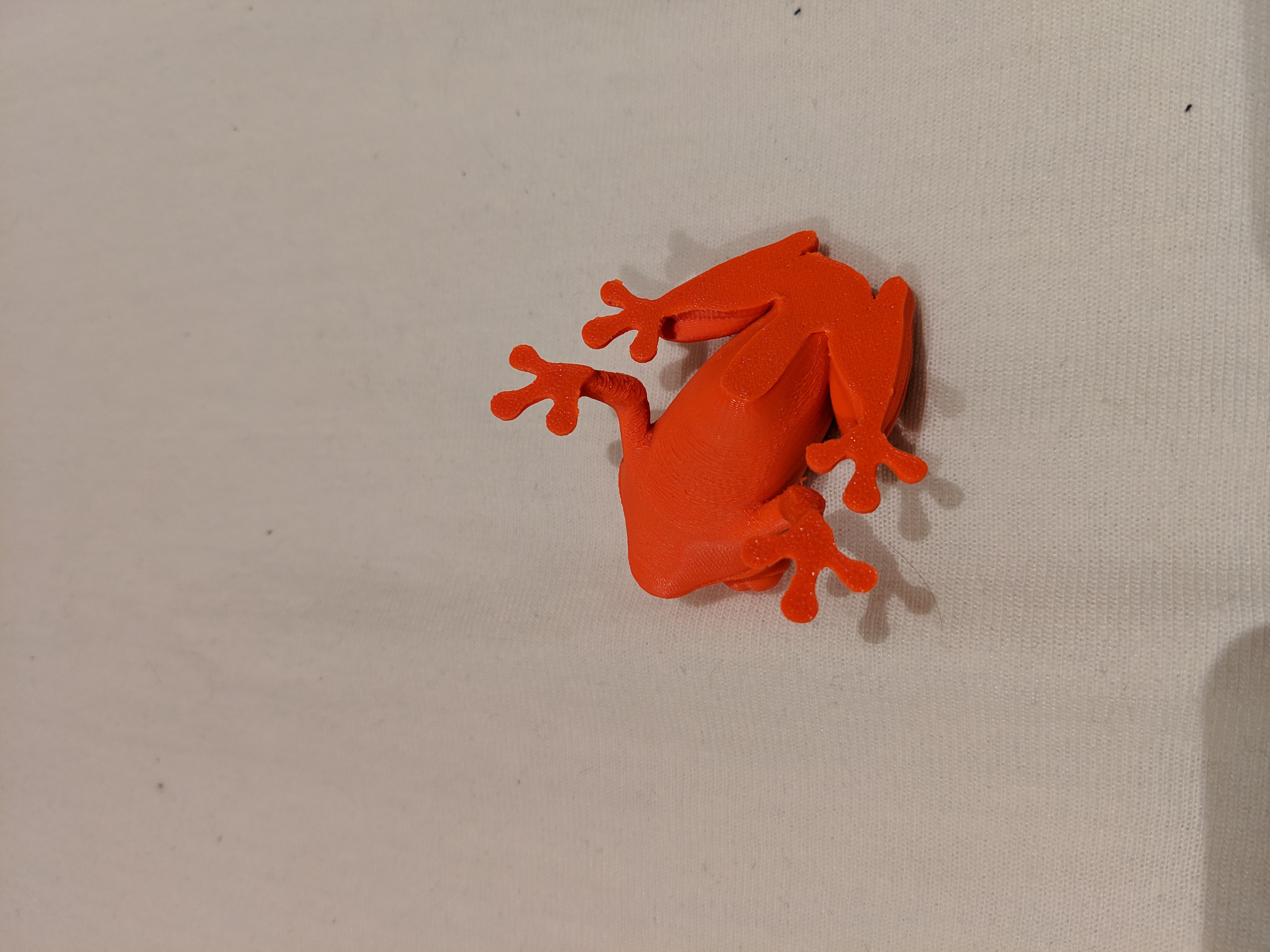

I attached the results of the treefrog.

Overall quality seems ok to me, maybe someone else can comment on this?

I do see some issues on the back of the legs which I think is due to inproper cooling as it's printing at a higher temperature right now?

Maybe printing slower will help here as well which is the next thing I'm going to try.

Re: Extruder Clicking 0.10 layer height

So one thing I realized was that I changed the ptfe tubes in the hotend after printing Wood filament for a while which clogged the ptfe tubes.

Quite randomly I found the post on how to replace ptfe tubes in the MK3, which requires drilling out the tubes etc.

I tried replacing the tubes as per instruction but accidentally broke off my nozzle in the heater block.

So after that I just ordered a full new hotend to see if it would fix the issue and it actually did, it's now printing 0.05 without any issues.