Easiest way to remove Y carriage bearings to apply grease

My Y carriage rattles like a bag of bones and I'm assuming it's the bearings. From what I've read, I should've greased them before installing them. I think I'm going to pull them off and pack them with some SuperLube soon.

My question is, what's the easiest way to get to the bearings on the Y carriage? Can I just remove the clips that hold the smooth rod in place and slide them off one end? I don't really want to have to tension and adjust my belt again if at all possible (it's sitting at about 270 right now which seems about perfect).

Just wondering if anyone has a simple procedure to get to the bearings with the least amount of disassembly? Thanks.

RE: Easiest way to remove Y carriage bearings to apply grease

Print the belt tension gauge that Prusa posted on the prints library. Throw away the sensor readings - they are crap.

Yes, you got it. Remove the bed. Remove the clips. Remove the bearings. Hope you have the little thing that screws onto the grease tube to lube the bearings. pack them good. Put it back together. Adjust the belt. No avoiding that.

RE: Easiest way to remove Y carriage bearings to apply grease

No, no, no. Lubrication cannot be your problem. Do some checking to see what is rattling, because it is guaranteed it is not worn bearings.

The bearings are made of Delrin, which has a high abrasion resistance and a very low coefficient of friction. A dot of silicone oil is all you ever need, like it says here.

If your bearings are rattling around like "a bag of bones" something is damaged or maladjusted. Packing it with grease will make a mess and will not fix the problem.

Cheers, mate.

RE: Easiest way to remove Y carriage bearings to apply grease

I would suggest temporarily removing the belt and checking to see if the Y axis carriage slides smoothly and without play or sticking. Without the belt, there should be essentially no resistance felt and the assembly should slide forward and backward easily and there should be no slop or play in the system. This is a good sanity check to be sure that the assembly is in proper order.

RE: Easiest way to remove Y carriage bearings to apply grease

I’ve done some more sleuthing and I actually think it might be the nylock mod that is causing the rattles. I’m going to switch to using the silicon method as well when I take off the heat bed.

During assembly, my Y axis moved pretty smoothly but without greasing the bearings I do recall thinking it had a little more “scratchy” sound than I would’ve expected.

RE: Easiest way to remove Y carriage bearings to apply grease

I use a syringe and apply lubrication right to the rods. Then I move the bearing up and down the rod to spread it around.

--------------------

Chuck H

3D Printer Review Blog

RE: Easiest way to remove Y carriage bearings to apply grease

No, no, no. Lubrication cannot be your problem. Do some checking to see what is rattling, because it is guaranteed it is not worn bearings.

The bearings are made of Delrin, which has a high abrasion resistance and a very low coefficient of friction. A dot of silicone oil is all you ever need, like it says here.

If your bearings are rattling around like "a bag of bones" something is damaged or maladjusted. Packing it with grease will make a mess and will not fix the problem.

Cheers, mate.

I am afraid I beg to differ with parts of this.

I too followed the manual, and my bearings were a bit grumbly on install, I stripped the printer back down after spesking to Prusa live chat, they advised packing with grease, which I did, now they are nice and quiet. (Although I packed using the rod and my finger to force the grease into the races as they sent me a video to illustrate this method)

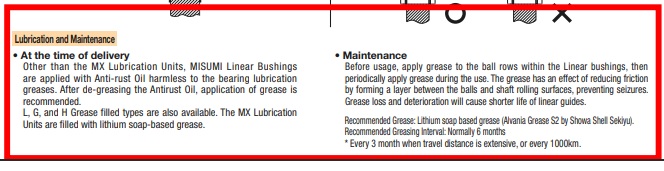

The standard bearings in the MK3 are not delrin, they are LM8UU Linear bearings.

https://uk.misumi-ec.com/vona2/detail/221000091803/?HissuCode=LM8UU#

The ball bearings are metal, running on a metal shaft and require lubrication, different people use different lubricants and methods. However Misumi recommend degreasing the shipping oil by soaking in 99% IPA and greasing correctly before installation, then regreasing every 6 months at least. Please see the manufacturers data sheet from Prusa.

https://forum.prusa3d.com/wp-content/uploads/2020/12/Misumi_Linearbearings.pdf

Prusa seem to be slowly changing/updating their install manual to reflect this advice from Misumi, the mini install manual shows the Misumi recommended method, I suspect the MK3 manual may follow suit at some point.

https://help.prusa3d.com/en/guide/3-x-axis-extruder-assembly_199519

There are rubber wipers front and back which serve as dust seals, it is also very tricky for grease/oil to get past these seals and properly lubricate the ball races. Rub some grease on your rods and you will find it pushed to either end, almost no grease gets past these seals.

Very much horses for courses, but I certainly will be keeping my LM8UU's well greased, and most probably when the next stripdown/grease is due I will replace the LM8UU's with Igus Drylin linear bearings, these seem to get good feedback, can be ran dry, or with lubrication and dont have the need for dust seals.

Just my 2 cents.

Tank you very much!

RE: Easiest way to remove Y carriage bearings to apply grease

Just in case you need to get to the bearings and really don't want to mess with the belt there is a way to do that.

Remove the 2 screws behind the lcd display that hold the belt idler. With that removed from the frame you can take the belt of the y-motor pully and move the bed without the belt attached to anything but the bed.

If you have the older style y-rod holders on the frame (pre MK3s+) you now just cut the zipties and lift the bed of the printer complete with the rod.

But it is a good idea to print the prusa belt tension gauge to check the belt before and after installing.

RE: Easiest way to remove Y carriage bearings to apply grease

Funny thing. This thread had me checking my bed for up and down motion this morning - a few weeks back I had changed out the linear bearings on X and Y for Drylins. Drylins are known to take some time to settle in - and when I first installed them, a day of printing later, there was some play (up and down) if I held the corner of the bed and checked for vertical play in the bed. At that time, i tightened down the bearing holders (no u-bolts for me - yay!) and that was that.

Today, I took off the bed, tightened the bearing holders again slowly one by one checking for the vertical play, until it was gone. If you switch out to Drylins, it's a thing you need to do till they are seated well.

Back to printing - 🙂

RE: Easiest way to remove Y carriage bearings to apply grease

@dan-rogers

Good to know Dan

Thanks for the update, think when my bearings start to run dry and need relubed ill give the drylins a go.

They dont look too expensive, saw 12 for around £13 plus postage.

Are you running them dry, or with lubricant? I believe both is an option, I though with them light oil would be a good option, something like SuperLube oil.

Tank you very much!

RE: Easiest way to remove Y carriage bearings to apply grease

Glad to see that Prusa is making some changes to the manual to address the grease packing debate.

I think I'll definitely remove the Y carriage and grease the bearings per the new Mini manual instructions. I have some SuperLube 21030 that people seem to think is pretty good for this purpose.

As for the X carriage bearings, I have no idea how hard it will be to remove the smooth rods from the Z axis carriers. I watched one video that implied the rods loosen in the carriage over time so maybe it wouldn't be as hard to get them back in as during first assembly.

RE: Easiest way to remove Y carriage bearings to apply grease

@clarmrrsn

I'm running them dry as the instructions said no lubricant. They have a lubricant built in that oils or other can interfere (according to instructions they came with). I am totally happy with them even with the occasional seat-in steps - it doesn't take more than 10 min to remove the bed and readjust. The huge gain I got with them is my carriage and X axis moves are nearly silent now. Of course the Moon's steppers had a lot to do with that too.

RE: Easiest way to remove Y carriage bearings to apply grease

@dan-rogers

I think that is part of the problem with a lot of folks. Almost an Asberger's approach to instructions....never should be rarely. I have lubricated mine and they work much better.

--------------------

Chuck H

3D Printer Review Blog

RE: Easiest way to remove Y carriage bearings to apply grease

@cwbullet

Oh cool! What are you using for lubricant? I'll give it a try!

RE: Easiest way to remove Y carriage bearings to apply grease

@cwbullet @dan-rogers

I was sort of a hybrid build, I followed the manual, except I cleaned the shipping oil off by soaking in IPA and wiped some grease inside the bearings with a piece of PTFE tube (I did not have the tool supplied with the mini), however this surface grease was pretty much all removed when I inserted the rod, and the bearings were still not quiet.

My bearings are actually reasonably silent after packing correctly with superlube, but when running by hand along the rod out the machine I could feel a very slight grumble, but not enough to be concerning.

Not convinced that the build quality of the bearings are that great, think drylins are the way forward.

Tank you very much!

RE: Easiest way to remove Y carriage bearings to apply grease

@clarmrrsn

Very respectfully, your own link disagrees with you. If you click on your link, is clearly says

| Lubrication Type | No |

|---|

https://uk.misumi-ec.com/vona2/detail/221000091803/?HissuCode=LM8UU#

The ball bearings are metal, running on a metal shaft and require lubrication,

RE: Easiest way to remove Y carriage bearings to apply grease

@tdk408

With the same amount of respect back might I suggest that you read the entire post, most specifically the manufacturers installation document for LM8UU Linear Bearings.

I saw this as well, but it is clearly a misprint on the Misumi site, You CANNOT run metal against metal without lubricant!!

If you wish to run your bearings like this, feel free, but expect some nasty noises and wear lines to appear. 😀

I have attached the Installation PDF for reference.

Tank you very much!

RE: Easiest way to remove Y carriage bearings to apply grease

@baklin

Thanks for the tip on the idler pulley mount. I was able to remove the bearings without messing with the belt at all. As you said, just loosening the mount allowed me to remove the belt from the motor shaft. From there you can just remove loosen the 4 screws that hold the smooth rods down and then remove the 8 screws that that hold them in place against the frame. That allows the rods to slide out and there's enough slack in the belt to twist the carriage over for easy access to the bearing brackets.

After soaking the bearings in IPA and then packing using SuperLube and the printed applicator tip they seem much quieter. I also went ahead and swapped the Nylock Mod for the Silicon Mod ( https://www.schweinert.com/silicone-bed-level-mod-prusa-mk3) which also seems to have eliminated some additional spots that can rattle.

I'm down to just one rattle that I can't seem to locate. It's weird b/c everything seems tight so it may just be the bearings themselves. I've read about changing the Y motor mount or wrapping it in a zip tie, but for the life of me I can't localize this rattle on the printer. I might have to try the cardboard tube method at some point.

It's definitely much better than before and I feel better knowing the bearings are greased. Thanks all for the help.

RE: Easiest way to remove Y carriage bearings to apply grease

@trimetric

Had a look at the silicone mod, it looks interesting.

I wondered about using m3 silicone washers between the nyloc and the bed (Nyloc Mod), and then a piece of silicone tubing between the nyloc and the frog that is slightly compressed. This should in theory eliminate all noise as act like shock absorbers while still making it easy to adjust.

I used fibre washers between the bed and nyloc nuts to try and minimise noise a bit, it helps a little, but silicone washers would be far superior.

Occasionally get the odd rattle, it could be down to the nylocs or the misumi linear bearings, they seem to have a bit of a track record of being noisy, it can be very difficult to eliminate these types of noises with ears alone.

Might go for Drylins sooner than anticipated, not feeling the love for the LM8UU's.

It is not causing any issues, just a bit annoying when you hear the odd feint buzz now and again

Tank you very much!

RE: Easiest way to remove Y carriage bearings to apply grease

@clarmrrsn

Yeah, sometimes you get the perfect movement that creates some weird resonance. I was printing this sheet holder ( https://www.prusaprinters.org/prints/51462-expandable-steel-sheet-holder-mk-mini) and you have to print the long parts diagonally across the heatbed b/c they are too long otherwise. The combination of X and Y movements caused the worst sound I've ever heard from my printer. I almost stopped it but finally figured out that it was just resonance and that I could quiet it by holding a few places on the frame.

The silicon mod was actually pretty simple. I thought it would be hard to get the screws aligned but it really wasn't too bad. It did take a bit more pressure on the heat bed than I thought to get the threads started. The biggest problem is that you really have to start one at a time so you need a bit of uneven downward force on each corner/side at a time to start the screw. I was wondering if 10mm is too wide to start, maybe cutting that down to 9mm would require slightly less compression and make it easier to get started. When I was done, they were squished pretty good so I feel like they could be slightly thinner and still accomplish the goals.

Your combination idea might be perfect as it would prevent having to use the heated as leverage on the silicon initially but still provide that damper between the bed and the nylock nut. The same tubing should work (3mm ID, 7mm OD), probably just cut down to maybe 2-3mm in a jig instead of 10mm. Definitely worth a try.